Automatic hooping machine

The technology of a hoop hoop machine and a hydraulic cylinder is applied in the field of hoop production and processing accessories, which can solve the problems of inconvenient adjustment, high use limitation, poor use reliability, etc., so as to reduce the use limitation, improve the supporting capacity, and facilitate fixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

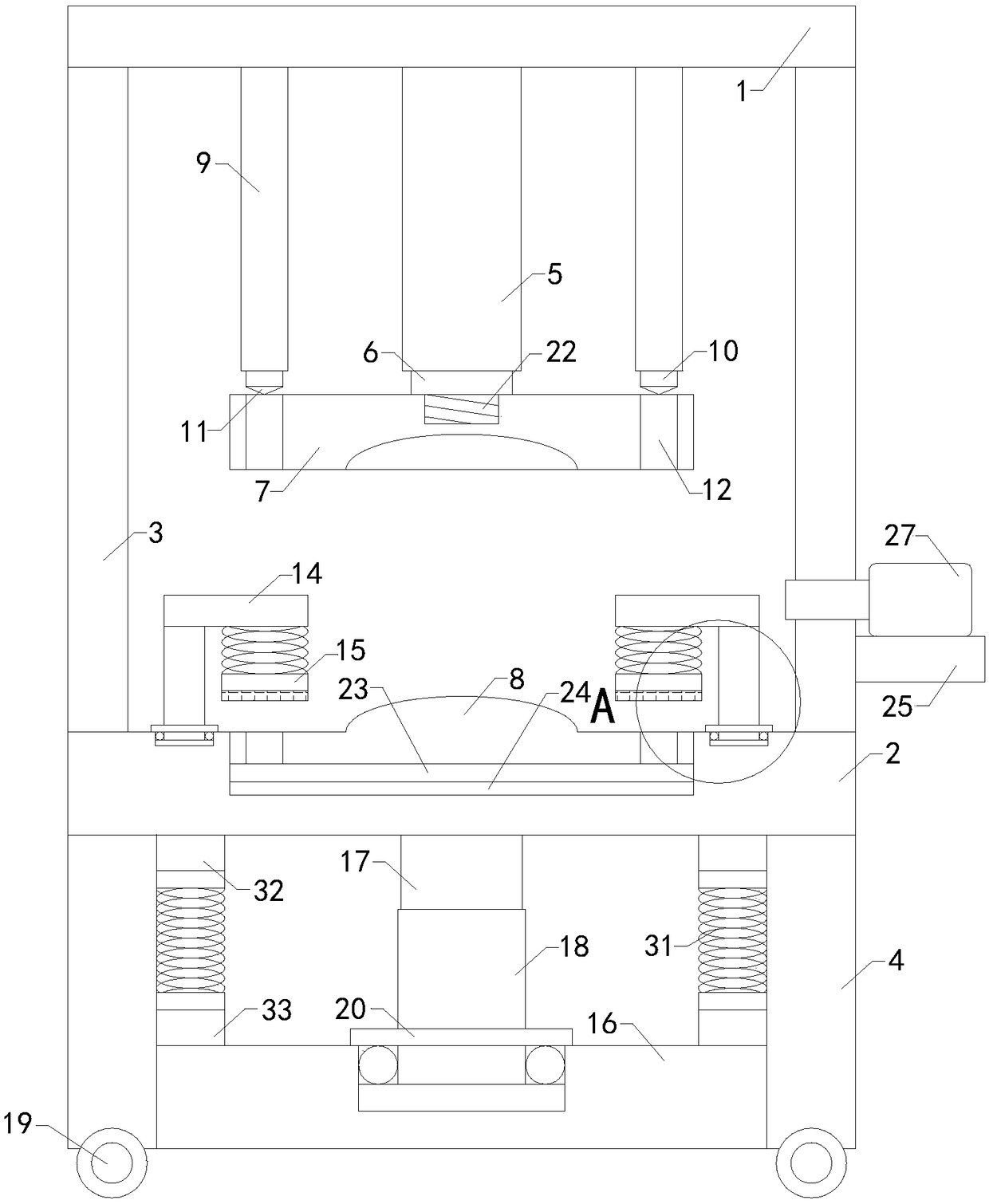

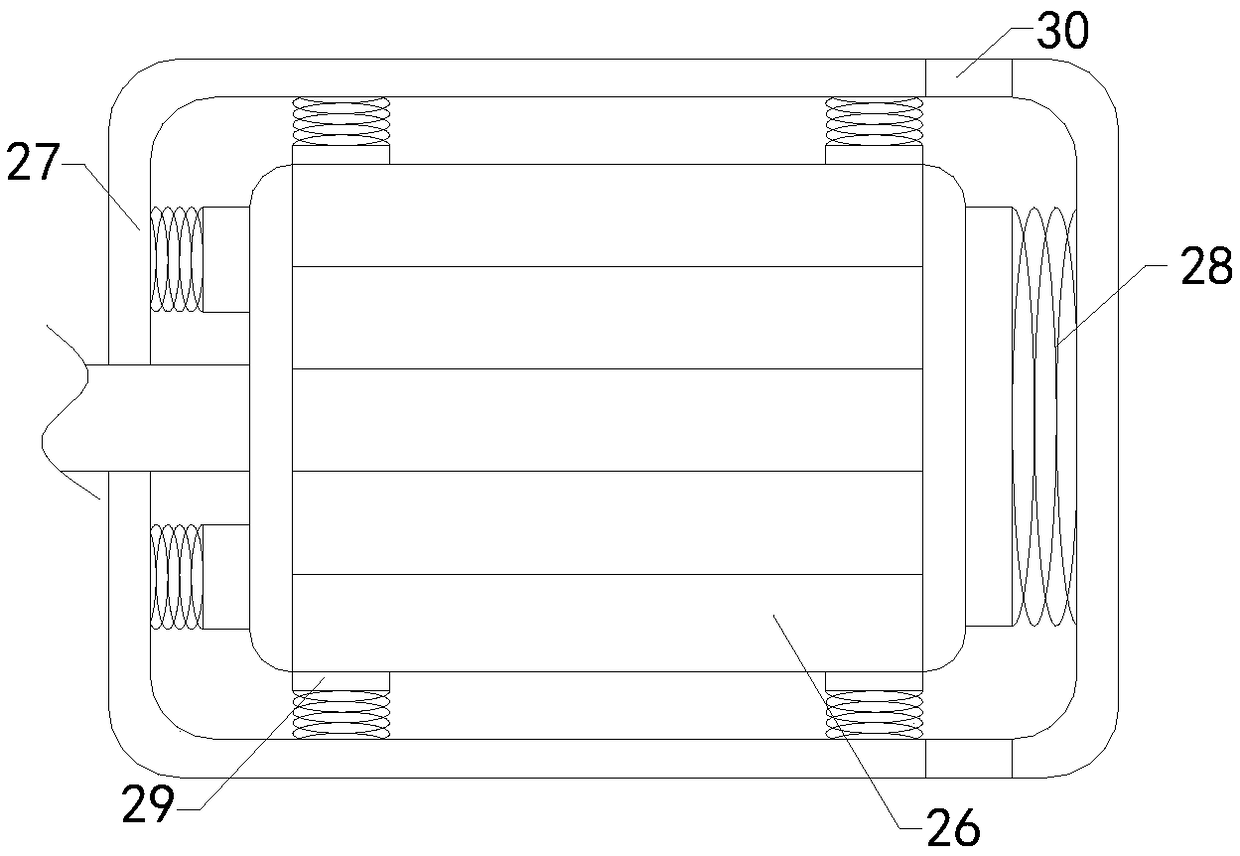

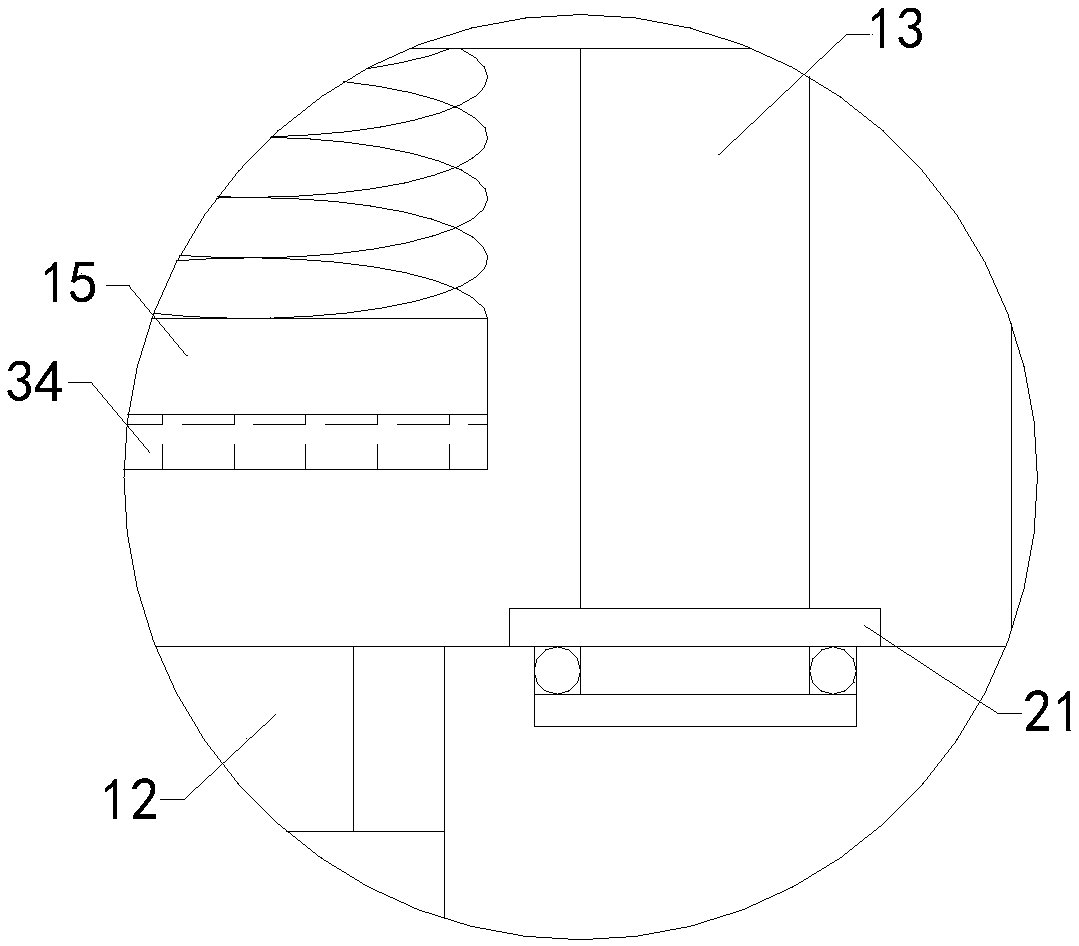

[0018] Such as Figure 1 to Figure 3 As shown, an automatic hoop machine of the present invention includes a top plate 1, a bottom plate 2, a left side plate 3, a right side plate, four sets of supports 4, a first hydraulic cylinder 5, a first telescopic rod 6, an upper template 7 and Lower formwork 8, the tops of the left and right panels are respectively installed on the left and right sides of the bottom of the top panel, the bottoms of the left and right panels are installed on the top of the bottom panel, and the tops of the four sets of brackets are respectively installed on the bottom panel The left front side, the right front side, the left rear side and the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com