Spraying granulating machine for nano metal powder production process with sundry cleaning function

A nano-metal powder and sundry cleaning technology, which is applied in spray evaporation, liquid separation into beads and granulation, solid separation, etc., can solve the problems of lower product quality rate, inconvenient operation for users, and blockage of feeding port, etc., and achieve improvement Excellent rate, easy to clean and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is attached Figure 1-4 The present invention is described in further detail.

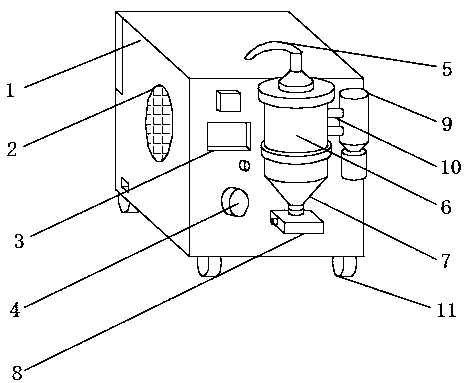

[0027] A spray granulator for the production process of nano metal powder with the function of cleaning up debris, including a body 1,

[0028] Such as figure 1 As shown, the front outer surface of the body 1 is inlaid with a display screen 3, and the front outer surface of the body 1 is provided with a pressure gauge 4 near the position of the display screen 3. After the body 1 is turned on, the display screen 3 will display numbers, so that the staff can understand When the body 1 is in the state, the pointer of the pressure gauge 4 will rotate with the internal state of the body 1. The upper surface of the body 1 is fixed with a delivery pipe 5, through which the body 1 can be connected with the drying tower 6. The front end of the body 1 The drying tower 6 is fixedly installed, and the moisture of the fog droplets inside the drying tower 6 evaporates and dries quickly, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com