Falling-film reactor

A falling film reactor and reactor shell technology, applied in membrane technology, chemical instruments and methods, gas treatment, etc., can solve the problem of uneven liquid distribution on the inner wall of the guide tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

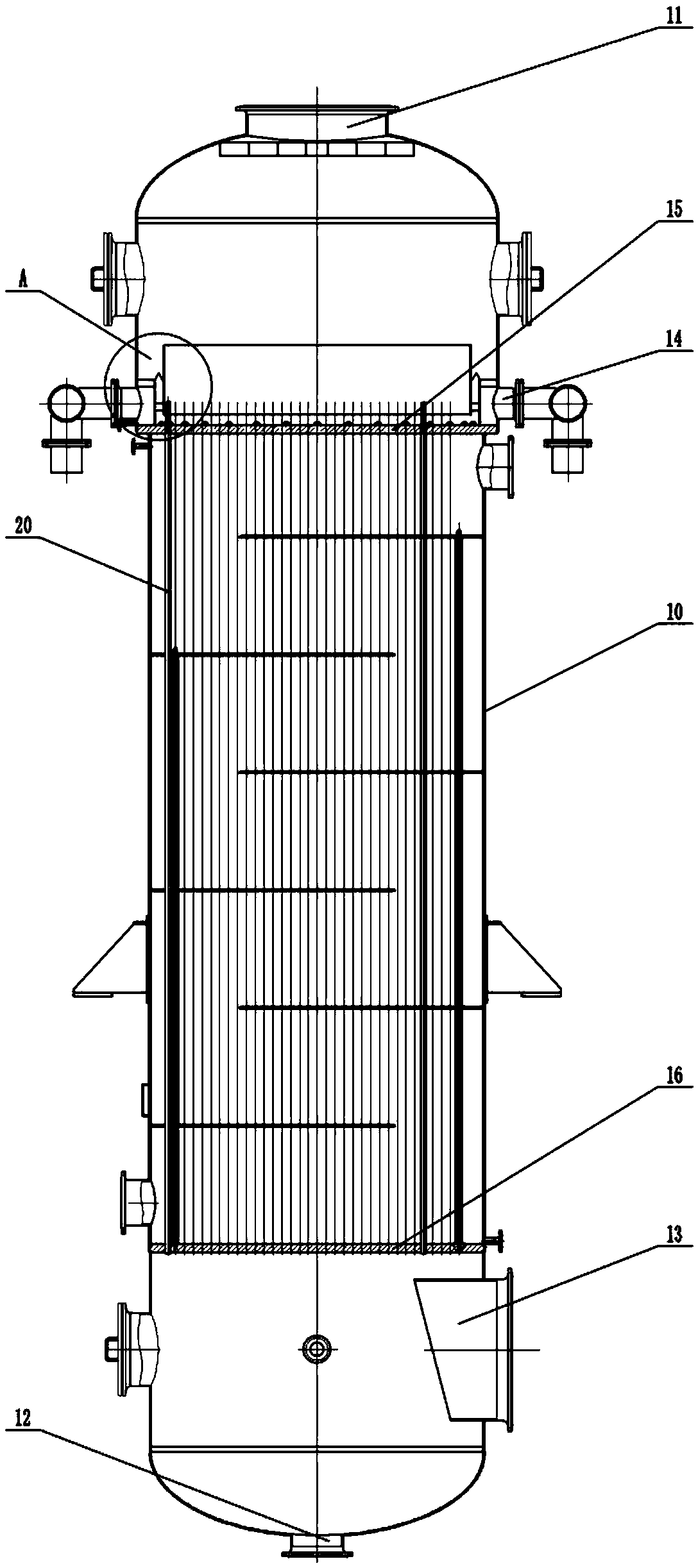

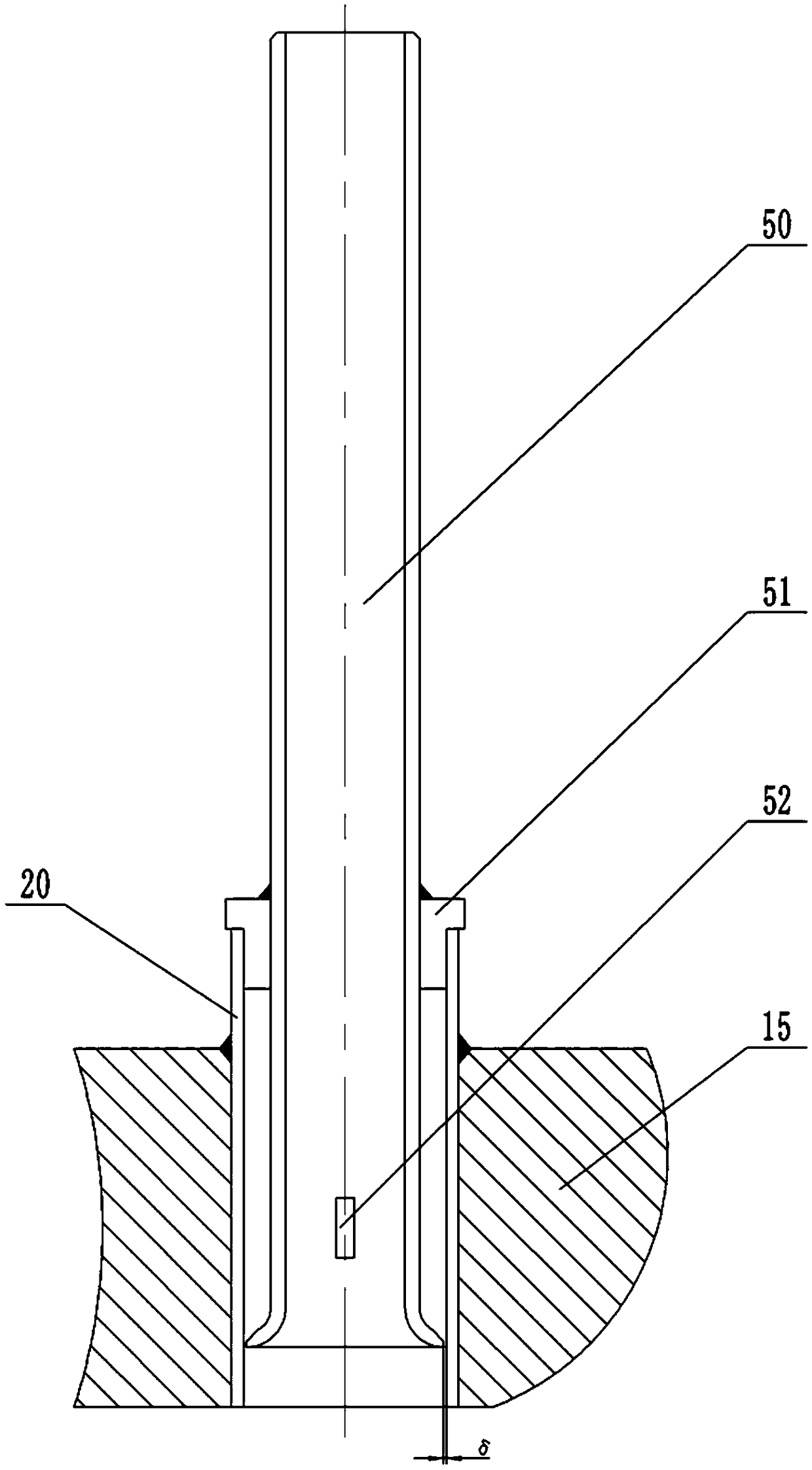

[0023] Instructions attached Figures 1 to 5 The reference signs in include: reactor shell 10, air inlet 11, liquid outlet 12, air outlet 13, liquid inlet 14, upper tube plate 15, lower tube plate 16, draft tube 20, liquid separation Barrel 30 , through hole 31 , zigzag groove 32 , flow channel 33 , overflow plate 40 , falling film reaction head 50 , L-shaped stop block 51 , center positioning block 52 , and liquid channel 60 .

[0024] Such as figure 1 , figure 2 Shown, a kind of falling film reactor comprises reactor shell 10, and the top of reactor shell 10 has air inlet 11, and the bottom of reactor shell 10 has liquid outlet 12, and reactor shell 10 The upper side wall is provided with a plurality of liquid inlets 14 , in this embodiment, there are eight liquid inlets 14 , and the eight liquid inlets 14 are evenly distributed along the circumference of the side wall of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com