Broken fluff collecting device for textile machine

A collection device and textile machine technology, which is applied in the direction of combination device, dust removal, dispersion particle separation, etc., can solve the problems of affecting production volume, endangering life, and affecting workers' lung organs, so as to improve the range of absorbing dandruff, and the device The effect of stable operation and improved transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

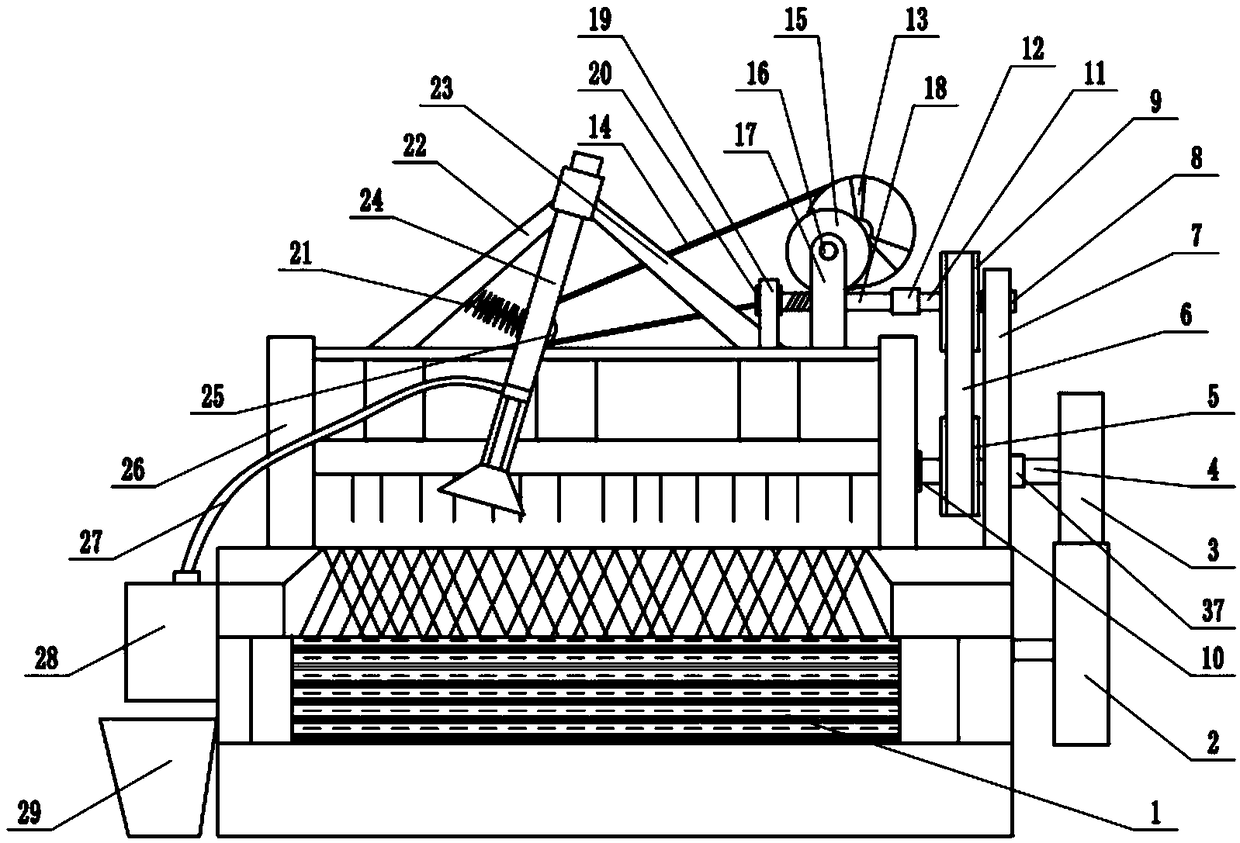

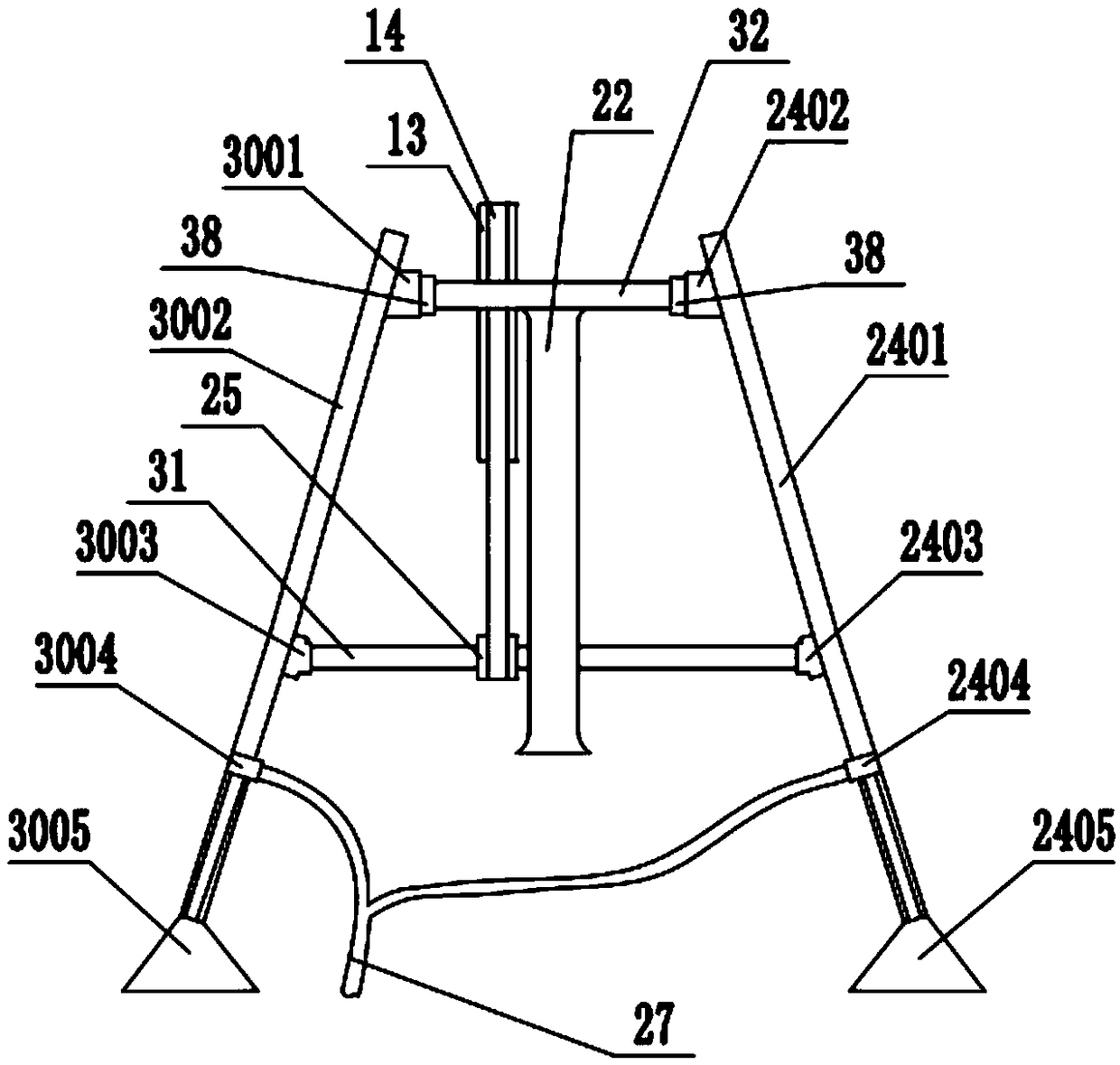

[0019] A method for collecting scraps from textile machines, the method is to drive the left and right swing of the collection bracket through the rotation of the gear assembly, the transmission of the synchronous belt, the transmission deceleration of the worm gear 15 and the worm 18, and the swing motion of the eccentric wheel 13, and through the sucker to the working The loom 1 in the loom performs the process of cyclically swinging and absorbing the debris, and realizes the collection and treatment of the debris through the combined action of the collection box 28 and the waste collection barrel 29; the device is composed of the loom 1, the weaving Machine gear 2, first gear 3, first shaft 4, first synchronous wheel 5, first synchronous belt 6, first support 7, first bearing 8, second synchronous wheel 9, second bearing 10, second Shaft 11, coupling 12, eccentric wheel 13, second synchronous belt 14, worm wheel 15, third bearing 16, second support 17, worm 18, third support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com