Thimble anti-collision structure and ejector module

A thimble and anti-collision technology, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems that the thimble module is easily hit and damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

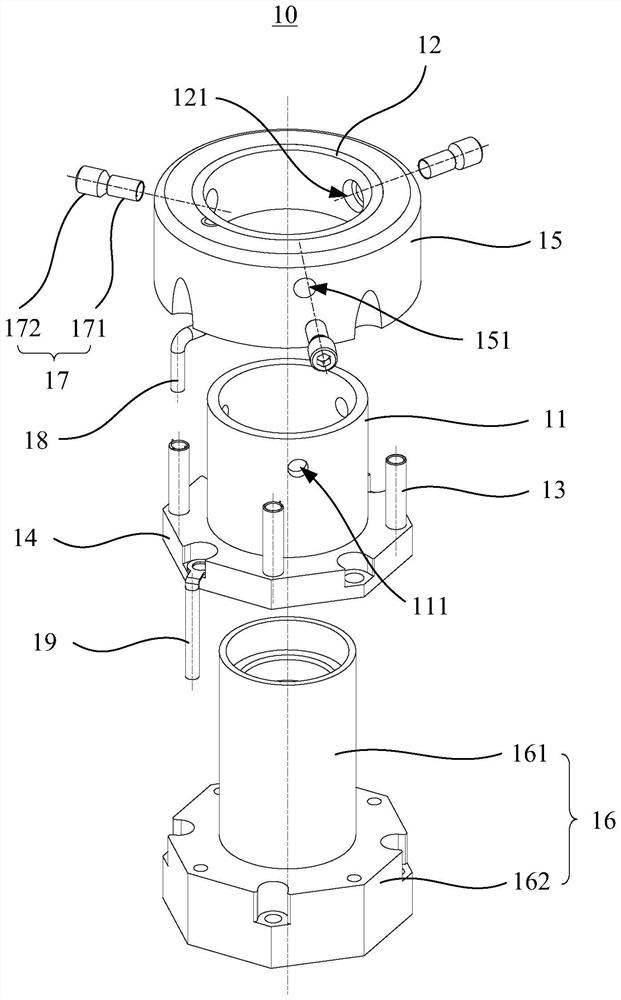

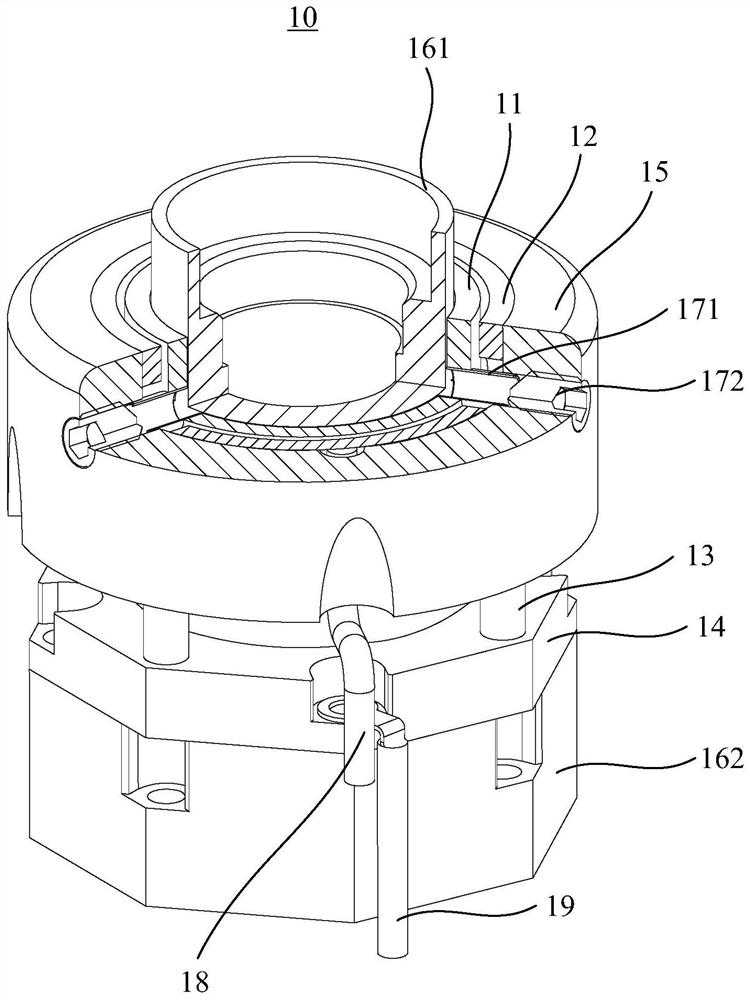

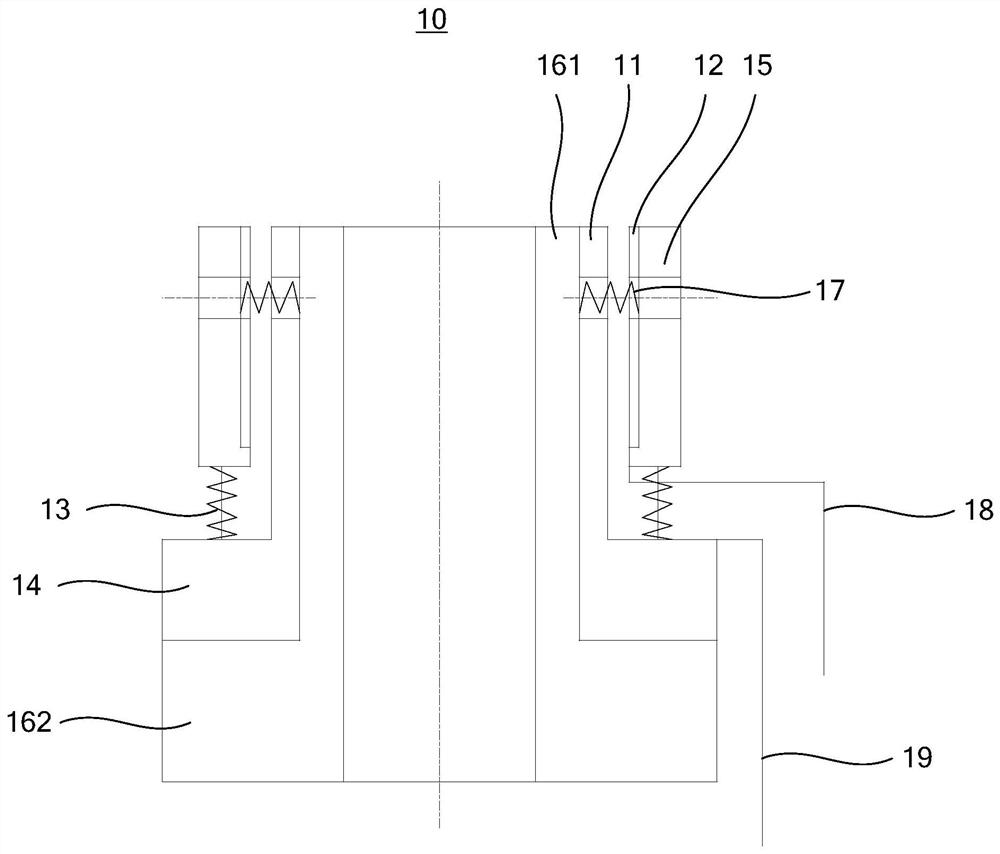

[0021] Such as Figure 1 to Figure 3 As mentioned above, in one embodiment, a thimble anti-collision structure 10 is provided, including a conductive cylinder 11 capable of inserting a thimble and a conductive ring 12 sleeved on the periphery of the conductive cylinder 11, and the outer periphery of the conductive cylinder 11 is provided with elastic A support member 13, one end of the elastic support member 13 is connected to the conductive cylinder 11, and the other end of the elastic support member 13 is connected to the conductive ring 12. When working normally, the conductive cylinder 11 is connected to the conductive cylinder 11. The conductive rings 12 are arranged at intervals, and the two are in a power-off state. When an external object hits, the conductive ring 12 moves relative to the conductive cylinder 11 , and the conductive ring 12 is in contact with the conductive cylinder 11 to be energized.

[0022] The above solution provides a thimble anti-collision struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com