An adjustable parallel seam welding fixture for surface mount ceramic shell

A ceramic shell and parallel seam welding technology, which is applied in the field of parallel seam welding fixtures and adjustable parallel seam welding fixtures, can solve the problems of poor sealing accuracy consistency, high seam welding quality requirements, and the shell cannot be put in, so as to improve production Efficiency, reduced production costs, simple and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

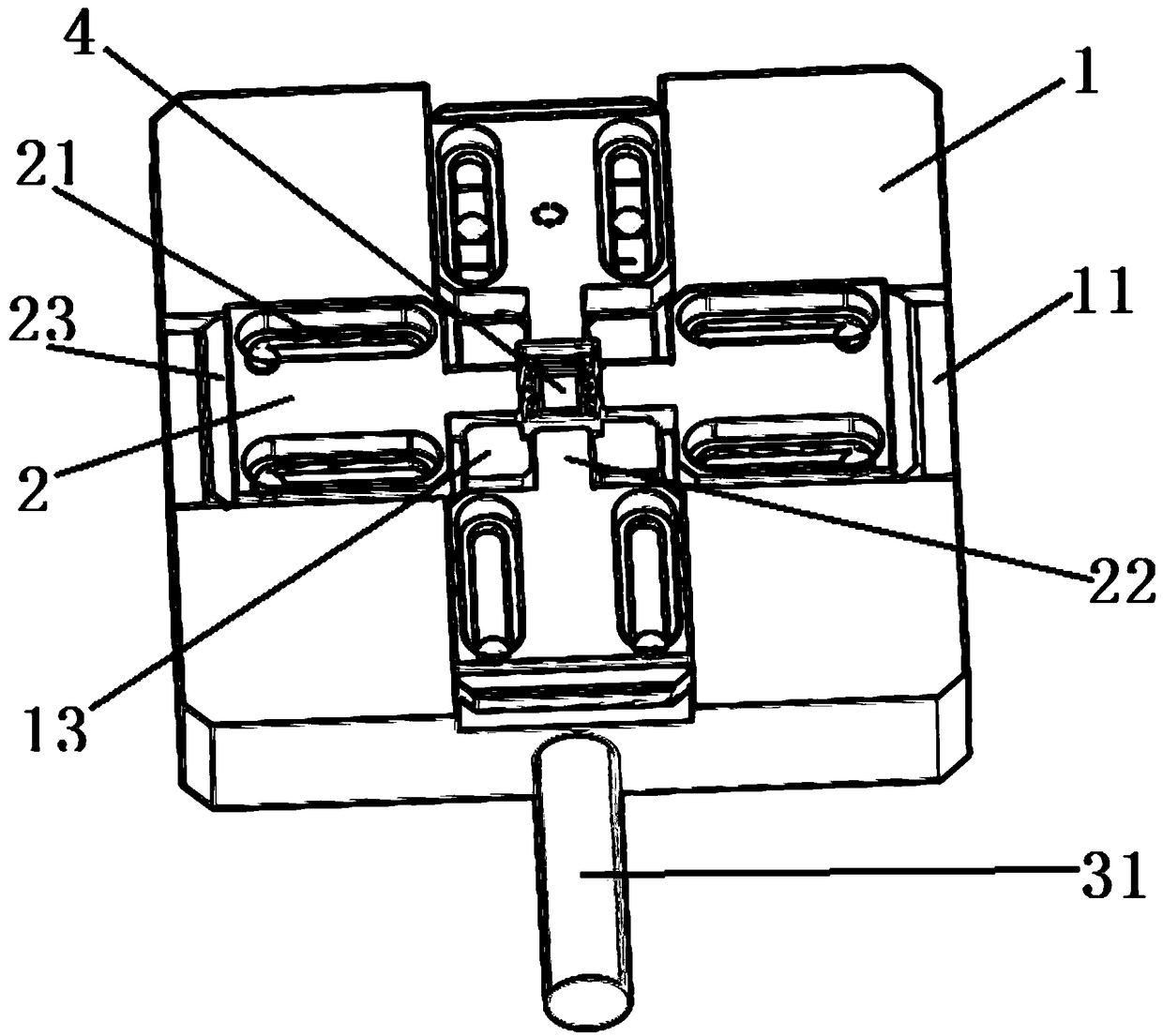

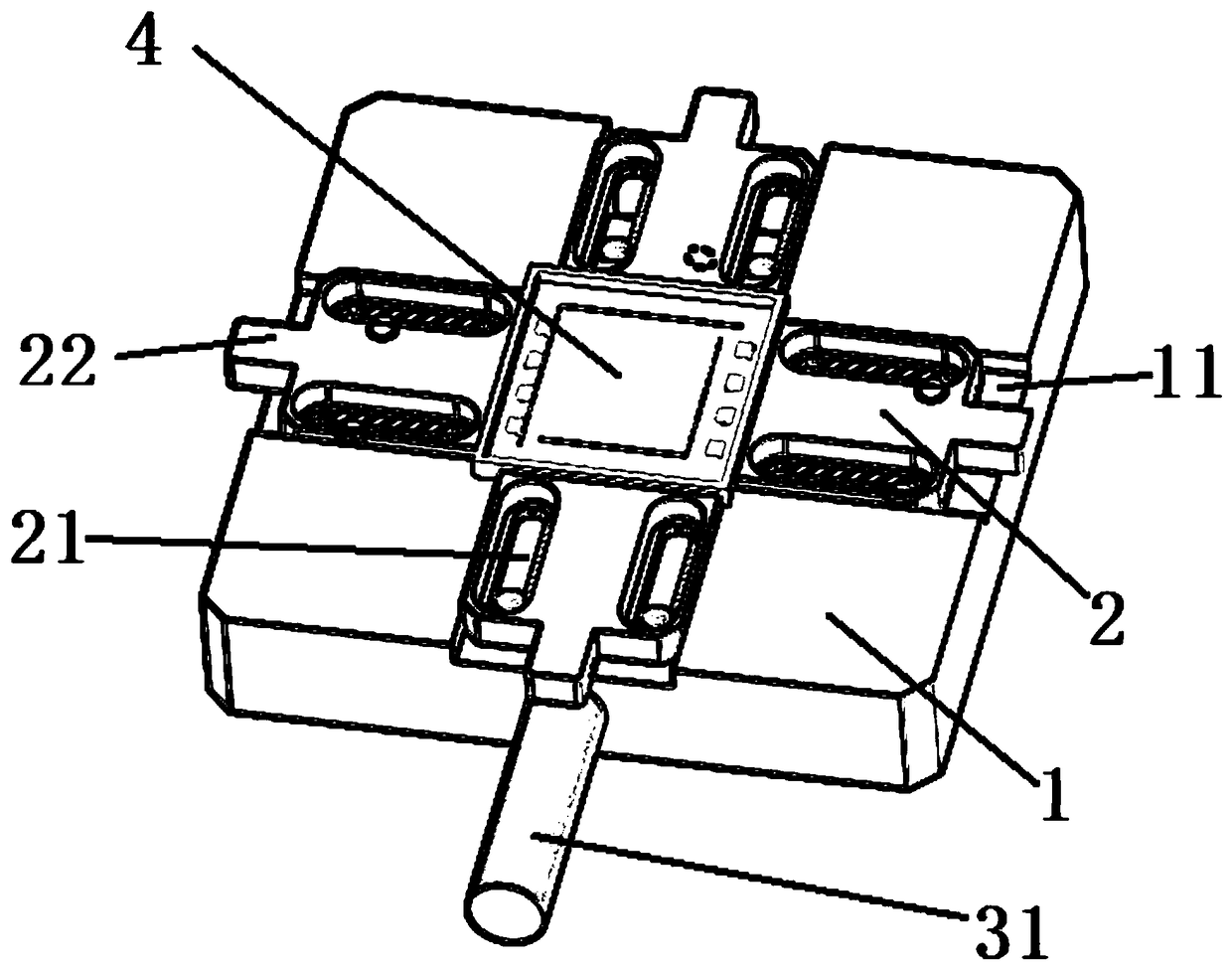

[0030] as attached figure 1 and figure 2 As shown, an adjustable parallel seam welding fixture for a surface mount ceramic case 4 includes a base 1 for placing the ceramic case 4 and four adjustable fixing blocks 2 for fixing the ceramic case 4 and a spring fixing assembly 3, four Two adjustable fixed blocks 2 are evenly distributed on the base 1, three of which can slide on the base 1, and the other adjustable fixed block 2 is fixed with a spring fixed assembly 3, and the spring fixed assembly 3 is connected with the base 1 Elastic fit.

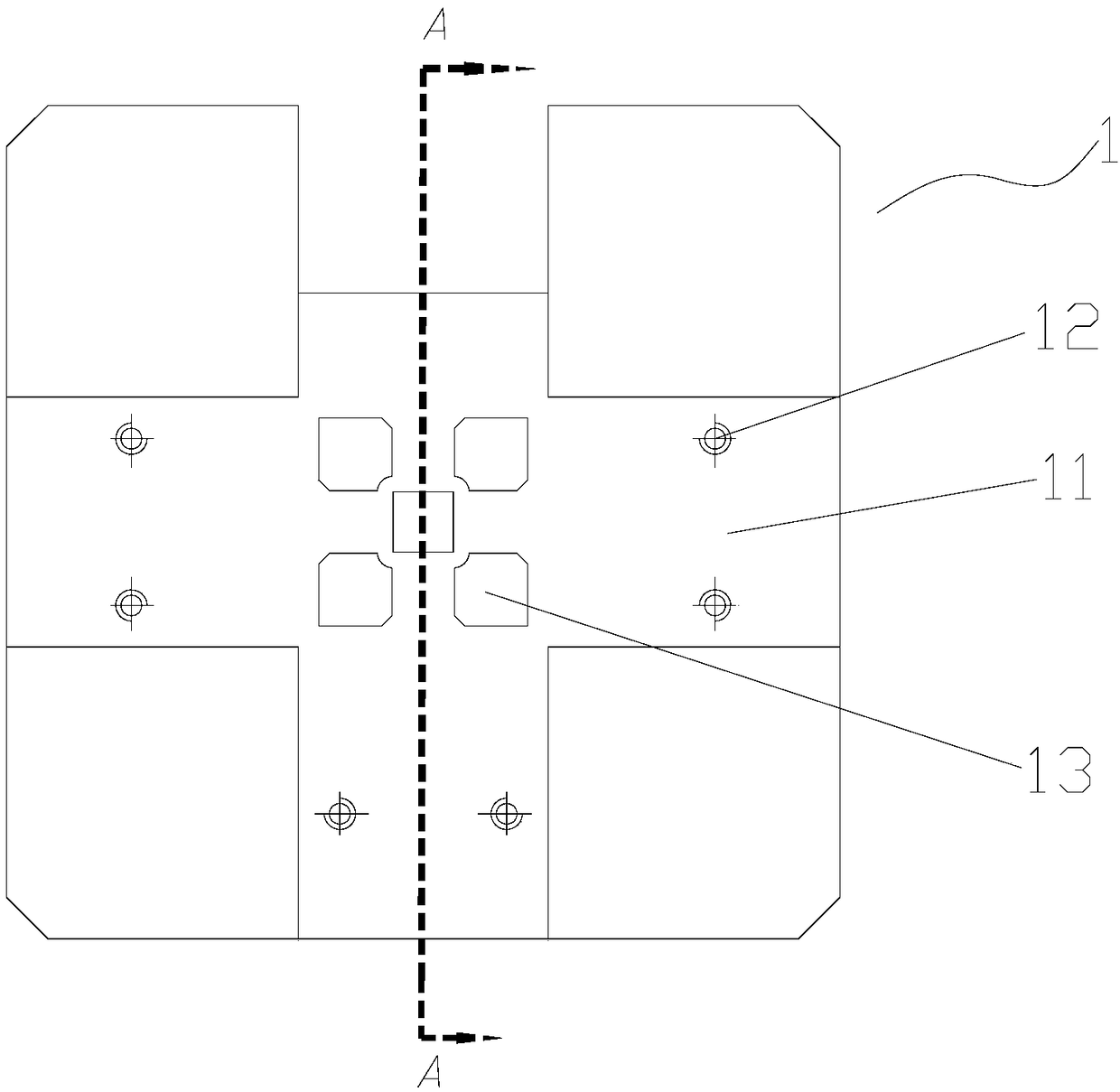

[0031] Such as image 3 As shown, the base 1 is provided with three grooves 11, and a threaded hole 12 is also provided in the groove 11. The center of the base 1 is provided with a boss 13 for carrying the ceramic shell 4. In this embodiment There are four bosses 13, which are evenly distributed;

[0032] Such as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com