Two-dimensional code-based inspection method and system

A technology of two-dimensional codes and inspection robots, which is applied in inspection time patrols, instruments, and sensing record carriers. It can solve the problems of limited space layout, difficulty in installing tracks, and increased manpower maintenance costs. It achieves convenient and flexible setup and maintenance. Low cost, avoiding the effect of inspection blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

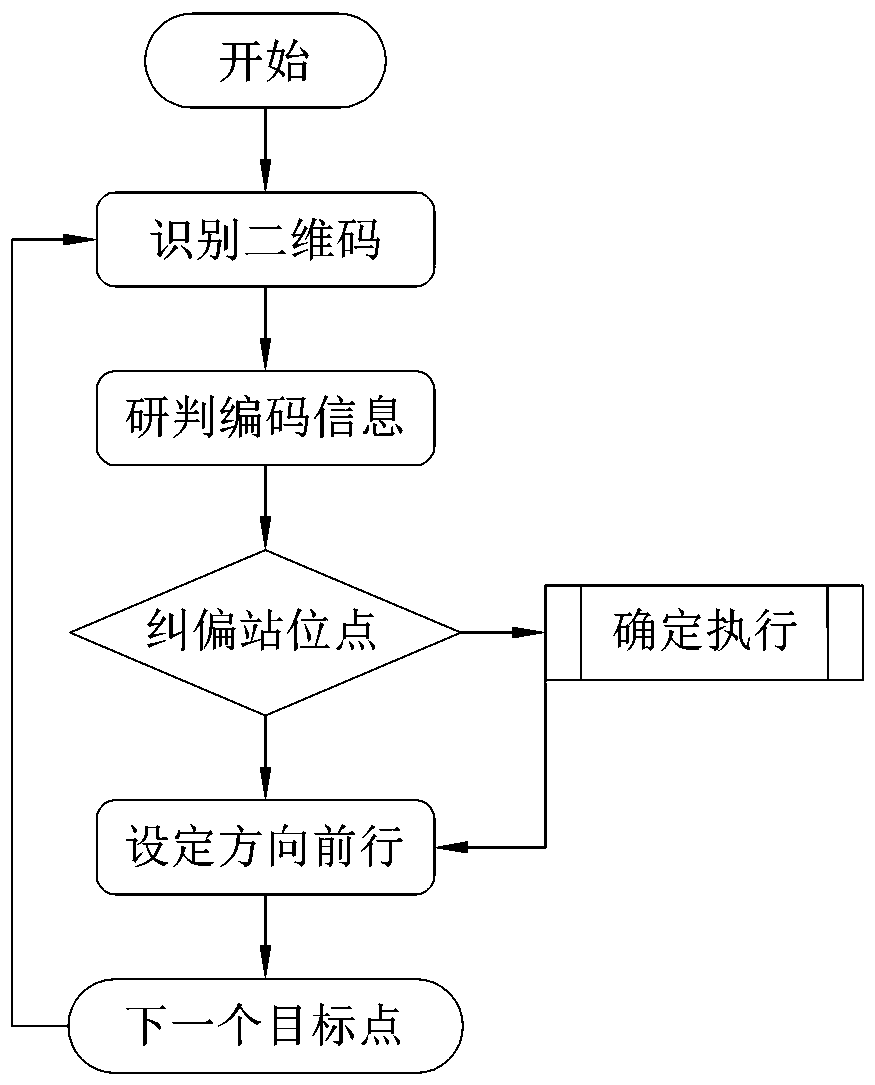

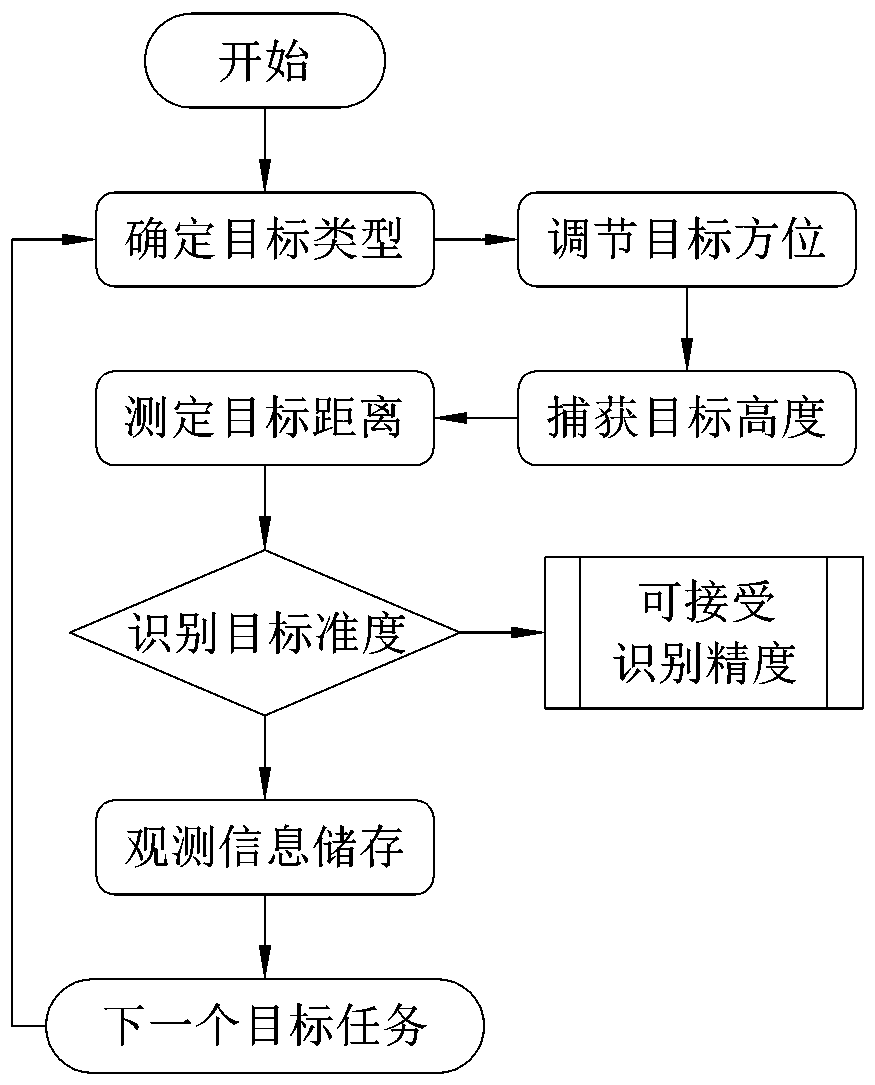

[0025] Embodiment 1: A two-dimensional code-based inspection method includes two parts: pre-preparation and actual inspection.

[0026] 1. Prepare in advance

[0027] Establish a coordinate system in advance in the substation room or substation to be inspected, which includes at least two vertical coordinate axes (X axis, Y axis) in the ground direction of the substation room or substation, A third coordinate axis (Z axis) perpendicular to the ground direction can also be included. Therefore, any point in the substation room or substation has the corresponding coordinates in this coordinate system.

[0028] Determine several observation points for performing observation tasks in the substation room or substation to be inspected, and determine the coordinates of these observation points in the coordinate system. Connect each observation point to form an inspection line. During the inspection, it is necessary to follow the inspection line.

[0029] Set a unique and correspon...

Embodiment 2

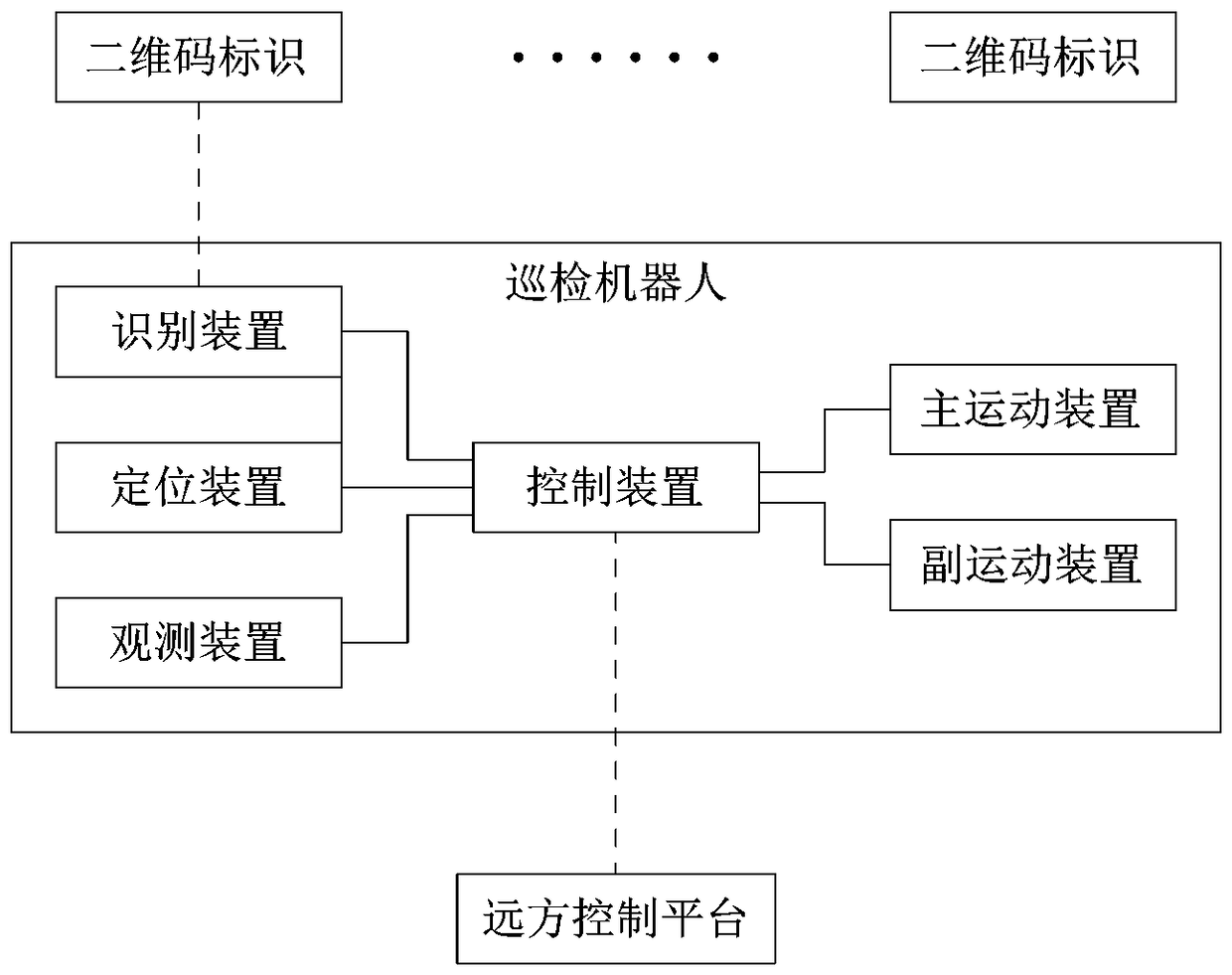

[0036] Embodiment two: as attached image 3 As shown, a two-dimensional code-based inspection system includes several two-dimensional code identification and inspection robots.

[0037] Establish a coordinate system in advance in the substation or substation to be inspected, and determine several observation points, each observation point has a coordinate in the coordinate system, and each observation point is connected to form an inspection line. The two-dimensional code identification is set in the distribution substation room or substation to be inspected with a coordinate system established, and corresponds to several observation points for performing observation tasks. The coded information identified by the two-dimensional code includes the coordinates of the corresponding observation point, the information on the direction of progress, and the information on the observation task to be performed at the observation point.

[0038] The inspection robot is used to identify...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com