Vibration sensor placement optimization method based on complex network theory

A vibration sensor, complex network technology, applied in instruments, electrical digital data processing, special data processing applications, etc., can solve problems such as poor results and inability to obtain modal information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

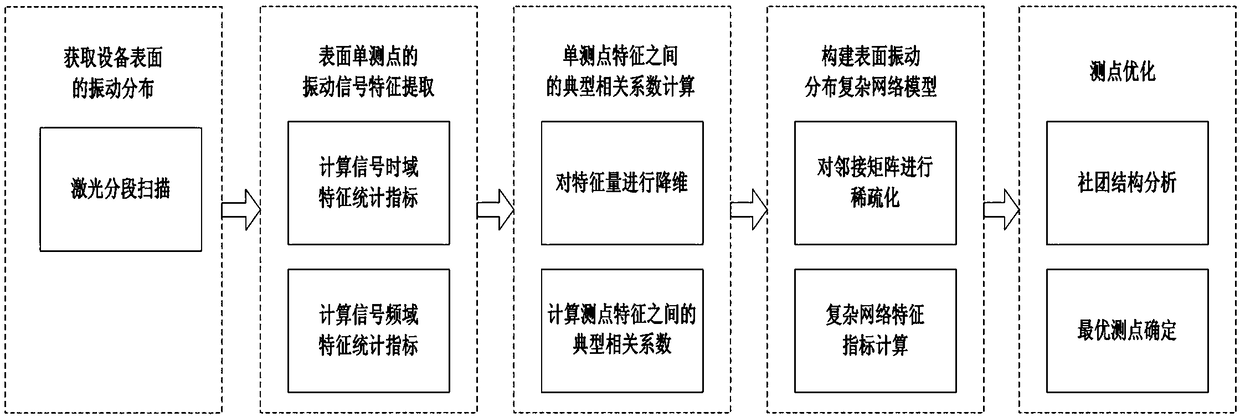

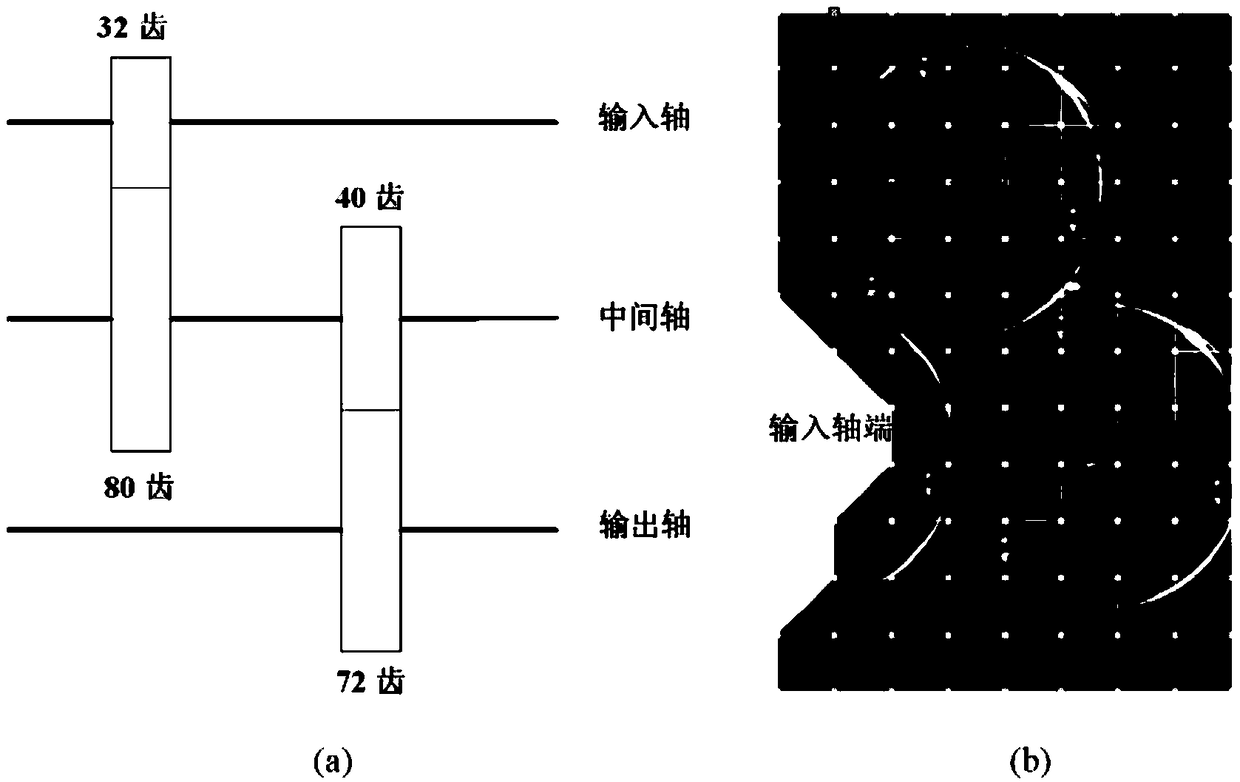

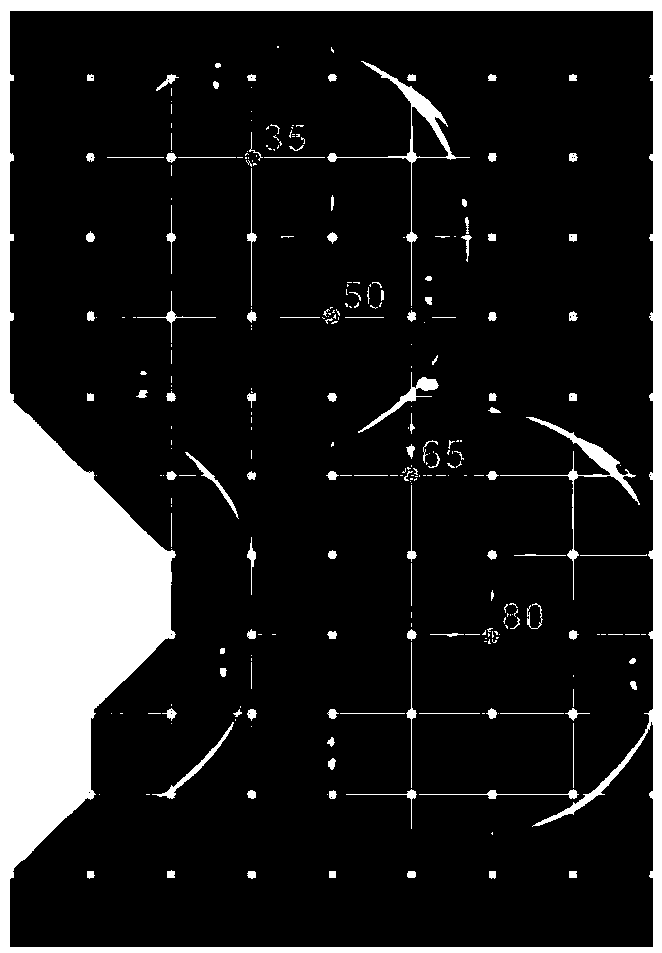

[0078] see figure 1 , the mechanical equipment surface vibration sensor measuring point layout optimization method based on the complex network theory provided by the present invention, its process mainly includes the following five steps: 1) Obtain the vibration distribution of the equipment surface; 2) Vibration signal of a single measuring point on the equipment surface 3) Calculate the typical correlation coefficient between the single measuring point features on the equipment surface; 4) Construct a complex network model of vibration distribution on the equipment surface; 5) Conduct community analysis on the constructed complex network model and determine the optimal sensor measurement point.

[0079] The invention uses a non-contact laser vibrometer to obtain vibration information on the surface of the equipment. This data collection method has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com