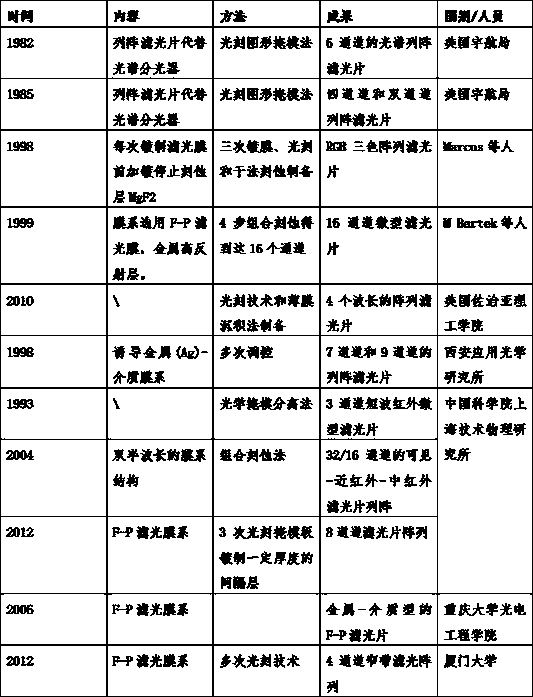

Preparation method for array F-P (Fabry-Perot) cavity optical filter

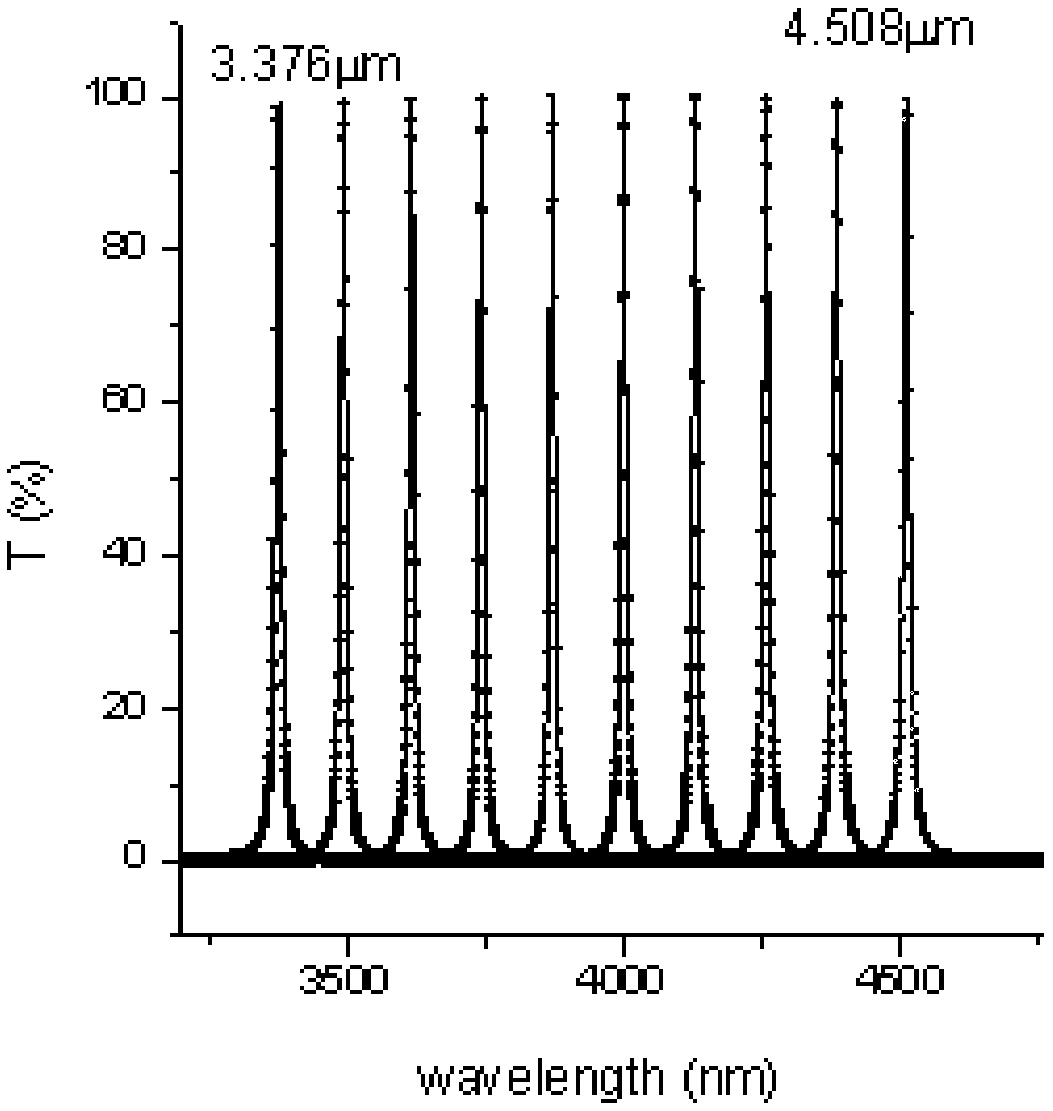

A F-P and optical filter technology, applied in the direction of optical filters, optics, optical components, etc., can solve the problems of low transmittance at the center wavelength of the filter and inaccurate position of the center wavelength, etc., to achieve precise control and accurate position High performance and high central transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

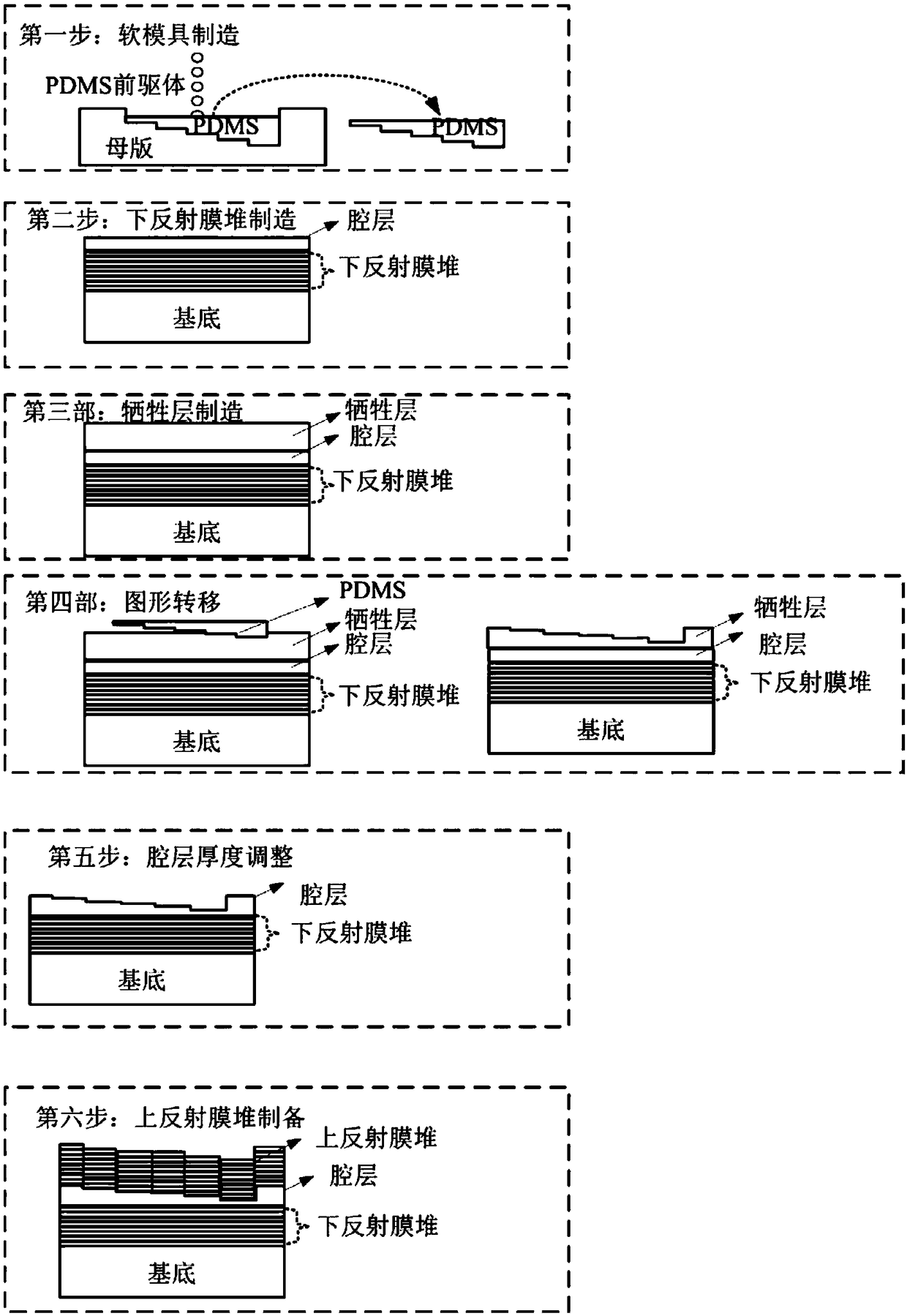

[0025] The following will be combined with figure 1 The present invention will be described in detail with Examples.

[0026] Preparation: the equipment used in the method of the present invention is a conventional equipment, first through ultrasonic cleaning on the zinc sulfide substrate, put into a vacuum chamber, and the local vacuum reaches 3 × 10 -3 Pa, turn on the ion beam evaporation source, the evaporation rate is 4A / s, the evaporation temperature is 230°, alternately deposit SiO 2 and three layers of Ge each, with a thickness of one-tenth of the wavelength; then deposit a cavity layer with a thickness of one-half, and the material of the cavity layer is SiO 2 .

[0027] A method for preparing an array F-P cavity filter provided by the invention comprises the following steps:

[0028] 1. Manufacture of soft mold: The hard mold is prepared by single-point diamond turning, and the thickness of the cavity layer is adjusted according to the mold pattern according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com