Power supply test platform system applied to testability verification test

A verification test and power test technology, applied in the field of testability verification, can solve problems such as low controllability and lack of fault injection methods, and achieve the effect of controllable injection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

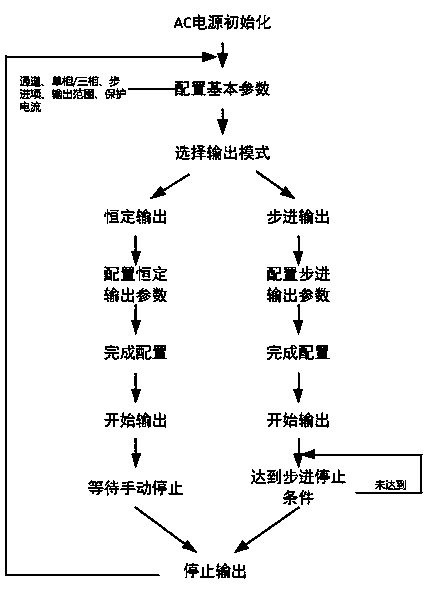

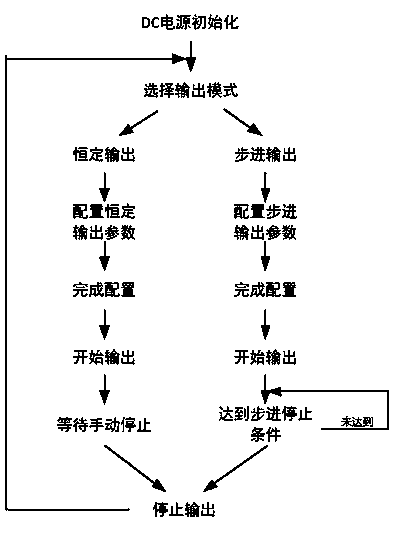

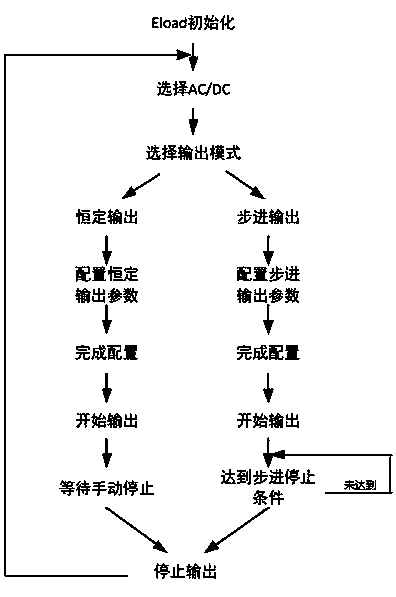

[0039] This embodiment is to inject power failures into products, and the system of the present invention is used to refer to the attached figure 1 As shown, this kind of power supply test platform system for testability verification test includes a high-frequency AC power supply 1, a high-power DC power supply 2, an AC-DC electronic load 3, a power switch 4, and an industrial computer 5. The industrial computer 5 is connected and controlled respectively. High-frequency AC power supply 1, high-power DC power supply 2, AC-DC electronic load 3, and high-power switch 4, wherein: the model of the high-frequency AC power supply is CSW5550, and the model of the high-power DC power supply is SGI500-20. The model of the AC / DC electronic load mentioned above is 63804;

[0040] The control software implemented in the industrial computer 5 is developed through Labview, including:

[0041] A high-power DC power supply control module 6 corresponding to the high-power DC power supply;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com