Device for measuring injection volume of ion chromatograph and method for measuring injection volume

An ion chromatograph and injection volume technology, which is applied in the field of ion chromatograph injection volume measurement devices, can solve the problems of easy evaporation loss of liquid, low gas flow rate, affecting the accuracy of verification, etc., and achieves reliable measurement method and high measurement accuracy. , the effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

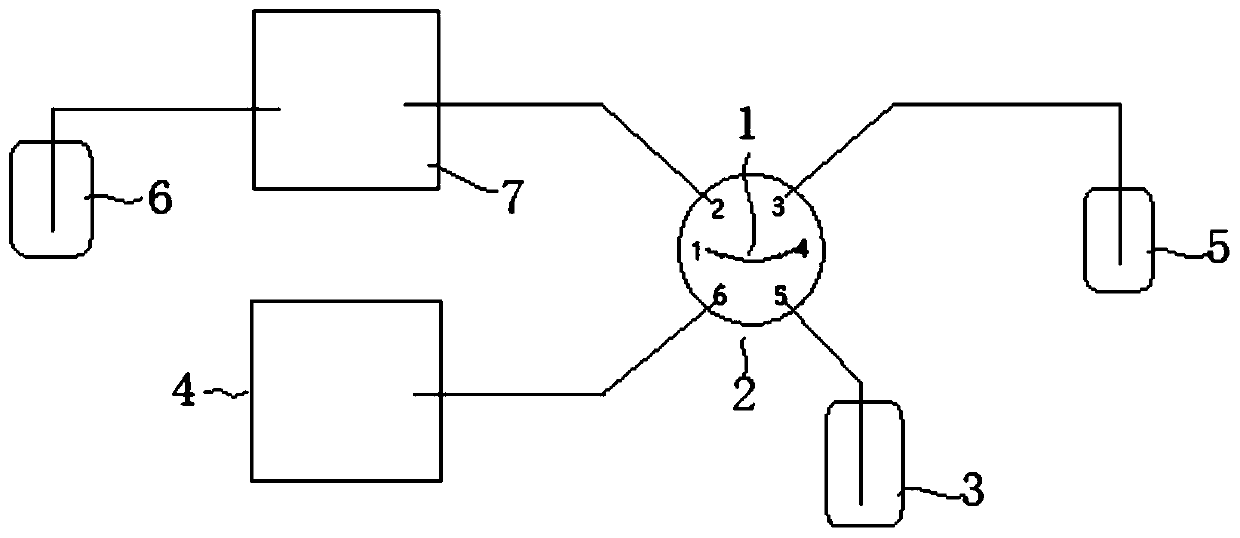

[0023] figure 1The sample injection valve 2 in the shown embodiment is a six-way valve, and the ports 1-6 are arranged sequentially; the two ends of the quantitative loop 1 are respectively connected to the port 1 and the port 4, the inlet of the infusion pump 7 is connected to the flushing solution 6, and the outlet is connected to the sample injection Port 2 of valve 2, receiving bottle 5 is connected to port 3 of sampling valve 2, sampling pump 4 is connected to port 6 of sampling valve 2, and measurement solution 3 is connected to port 5 of sampling valve 2. When the injection valve 2 is switched to the position where ports 2 and 3 are connected, ports 1 and 6 are connected, and ports 4 and 5 are connected, the infusion pump 7 and receiving bottle 5 cannot be connected to the port of quantitative loop 1, the flushing liquid channel is disconnected, and the sampling pump 4 and measurement solution 3 are connected to the interface of quantitative loop 1, and the measurement ...

Embodiment 2

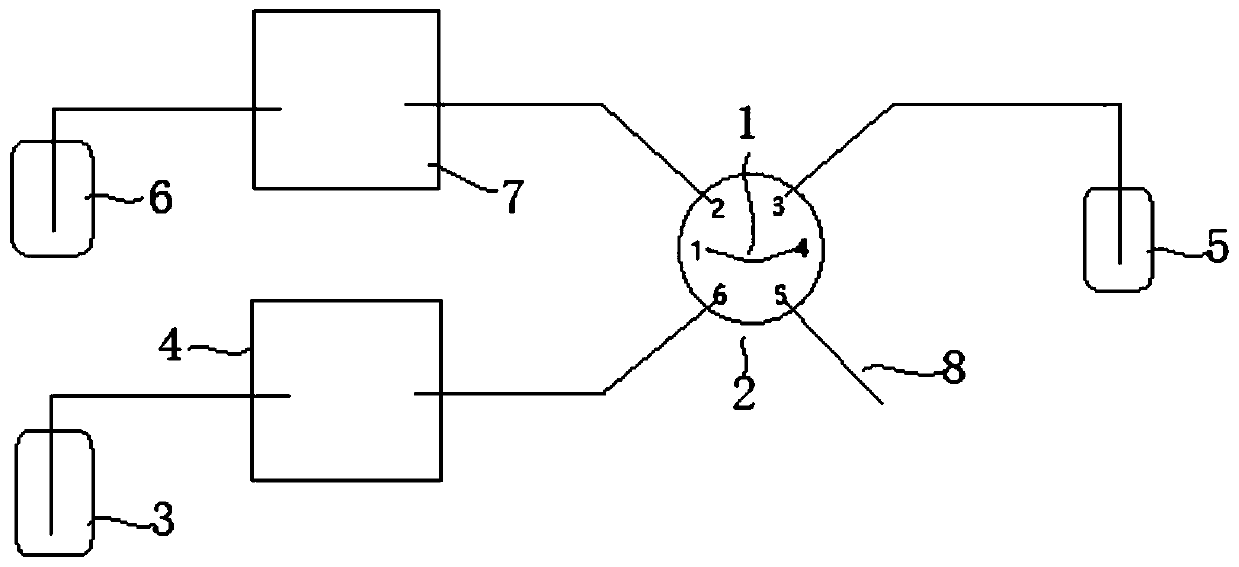

[0025] figure 2 Another embodiment shown with figure 1 The difference of the illustrated embodiment is that the inlet of the sampling pump 4 is connected to the measuring solution 3 , the outlet is connected to the port 6 of the sampling valve 2 , and the waste liquid pipe 8 is connected to the port 5 of the sampling valve 2 . This is an injection sampling method. First, the measurement solution 3 is sucked into the sampling pump 4, and then injected into the quantitative loop 1, and the excess waste liquid is discharged through the waste liquid pipe 8.

Embodiment 3

[0027] This embodiment is a method for measuring the injection volume using the measuring device of Embodiment 1. The prepared measuring solution 3 is an aqueous solution with a set concentration of 100 grams of water and 30 grams of sodium chloride, and the rinse solution 6 is pure water. Determination steps:

[0028] Switch the sampling valve 2 so that the infusion pump 7 and the receiving bottle 5 are not connected to the interface of the quantitative loop 1, the flushing solution channel is disconnected, the sampling pump 4 and the measurement solution 3 are connected to the interface of the quantitative loop 1, and the measurement solution channel is connected. Sampling pump 4, that is, the syringe pump. Before starting, the piston rod of the syringe pump is calibrated at the zero point of movement, and then the stroke of the syringe piston rod is calculated by the rotation of the motor, and the syringe pump is controlled to deliver a nominal value of 100.00 microliters of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com