Prestress concrete bridge corrosion fatigue life prediction method

A corrosion fatigue and life prediction technology, applied in bridges, bridge materials, bridge maintenance, etc., can solve the problems of increasing difficulty in determining fatigue damage parameters and complex stress states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] (1) Determine the elastic strain of concrete in the compression zone under fatigue load

[0079] First, calculate the elastic strain at the top of the concrete in the compression zone for:

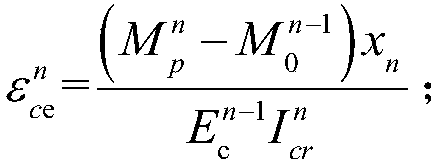

[0080]

[0081] In the formula, with are respectively the elastic modulus of concrete after n-1 times of fatigue and the bending moment effect caused by the effective tensile force of the steel strand; x n with are respectively the section bending moment effect caused by the vehicle load after n times of fatigue, the height of the compression zone and the moment of inertia of the cracked section, where x n You can refer to the calculation method for the height of the compression zone in the partially prestressed concrete flexural member.

[0082] The moment of inertia of the cracked section can be expressed as:

[0083]

[0084] In the formula, b is the section width; y n is the distance between the neutral axis of the cracked section and the edge of the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com