Propeller varying device of wind driven generator

A technology for wind turbines and casings, which is applied in the control of wind turbines, wind turbines, and combinations of wind turbines, can solve problems such as unsatisfactory pitch effects, improve safety and operational convenience, reduce bulky, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

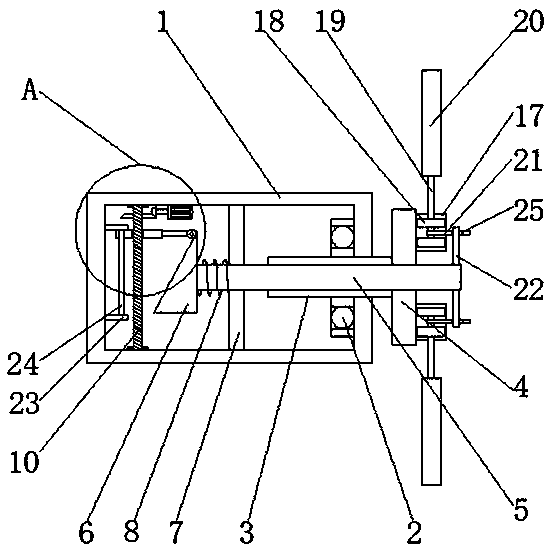

[0018] First implementation: see Figure 1-3 , a pitch control device for a wind power generator, comprising a casing 1, a first rolling bearing 2 is fixedly connected to the midpoint on the right side of the inner wall of the casing 1, a hollow main shaft 3 is movably connected to the inside of the first rolling bearing 2, and the hollow main shaft 3 The right end of the right end runs through the first rolling bearing 2 and the casing 1 from left to right in turn and extends to the outside of the casing 1 and is fixedly connected with the wind wheel disc 4, and the right side of the wind wheel disc 4 and the position corresponding to the hollow main shaft 3 is provided with a push rod 5 , the left end of the push rod 5 runs through the wind wheel disc 4, the hollow main shaft 3 and the casing 1 from right to left, and extends to the inside of the casing 1 to be fixedly connected with a triangular block 6, and the surface of the push rod 5 is located between the triangular blo...

no. 2 approach

[0021]The second embodiment: a pitch control device for a wind power generator, including a casing 1, a first rolling bearing 2 is fixedly connected to the midpoint on the right side of the inner wall of the casing 1, and the inside of the first rolling bearing 2 is flexibly connected There is a hollow main shaft 3, and the right end of the hollow main shaft 3 runs through the first rolling bearing 2 and the casing 1 from left to right and extends to the outside of the casing 1. A wind wheel disk 4 is fixedly connected to the right side of the wind wheel disk 4. And the position corresponding to the hollow main shaft 3 is provided with a push rod 5, and the left end of the push rod 5 runs through the wind wheel disc 4, the hollow main shaft 3 and the casing 1 from right to left in turn, and extends to the inside of the casing 1 and is fixedly connected with a triangular Block 6, the surface of the push rod 5 and the position between the triangular block 6 and the hollow main sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com