Assembled fan room

A prefabricated, fan technology, applied in ventilation systems, heating methods, space heating and ventilation, etc., can solve the problems of inflexible construction, inability to mass production and use, and achieve the goal of reducing construction pollution, flexible design, and saving resources and energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

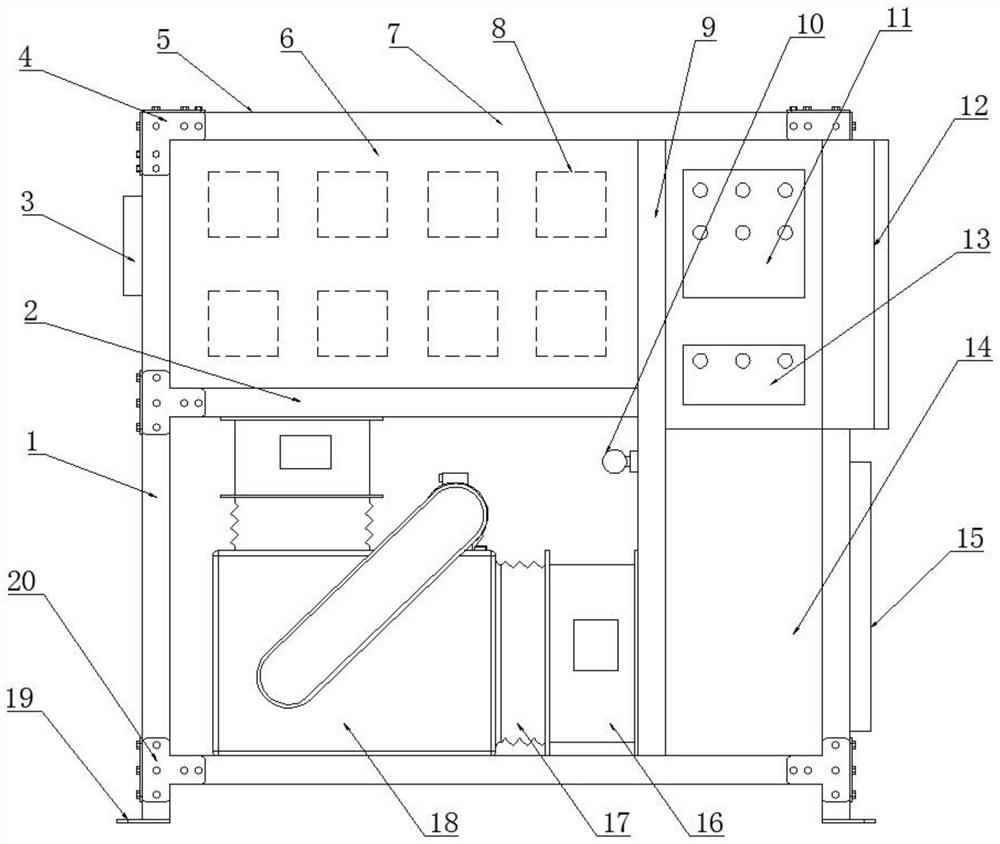

[0027] Embodiment 1 is basically as attached figure 1Shown: Assembled fan room, including the room body, the room body includes a plurality of columns 1, beams 7 and sealing plates 5 that are detachably connected to each other, there are four columns 1, eight beams 7, and five sealing plates 5 They are connected together to form a square room body with a front opening. The room is divided into a working chamber and a control chamber by a vertical partition 9, and a horizontal partition is arranged in the working chamber, and the vertical partition 9 and the horizontal partition all include two side-by-side support beams 2 and are fixed on two supporting beams. Support plate between beams 2. One end of the supporting beam 2 is provided with a stepped surface, and on the stepped surface, a plurality of slots are distributed along the length direction of the supporting beam 2. A supporting rod is bridged between the slots of the two supporting beams 2, and the supporting plate p...

Embodiment 2

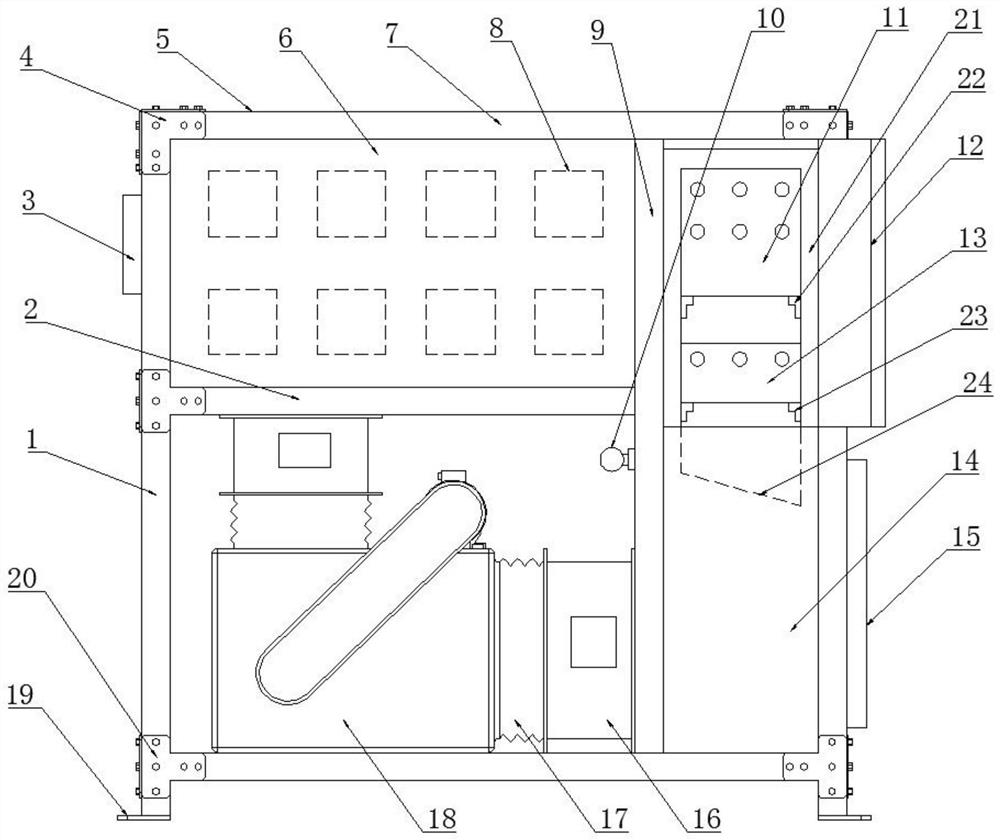

[0030] Embodiment 2, basically as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that a cooling mechanism is provided on the inner wall of the upper part of the control chamber, and the strong current control cabinet 11 and the weak current control cabinet 13 are installed on the cooling mechanism. The cooling mechanism includes a door-shaped support frame 21 detachably connected to the inner side wall of the upper part of the control chamber by screws. The inner side wall of the support frame 21 is welded with an upper mounting plate 22 and a lower mounting plate 23 from top to bottom. A heat-conducting graphite sheet is pasted on the inner side wall of the support frame 21. The upper mounting plate 22 and the lower mounting plate 23 adopt angle steel, the strong current control cabinet 11 is installed on the upper mounting plate 22 by screws, and the weak current control cabinet 13 is installed on the lower mounting plate 23 by screws. The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com