Knitting needle for knitting

A technology of knitting needles and needle shafts, applied in the field of knitting needles, which can solve the problems of reducing the knitting effect, not easy to take off loops, and coil wear, and achieve the effect of enhancing the effect of separating yarns, reducing the tendency of damage, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

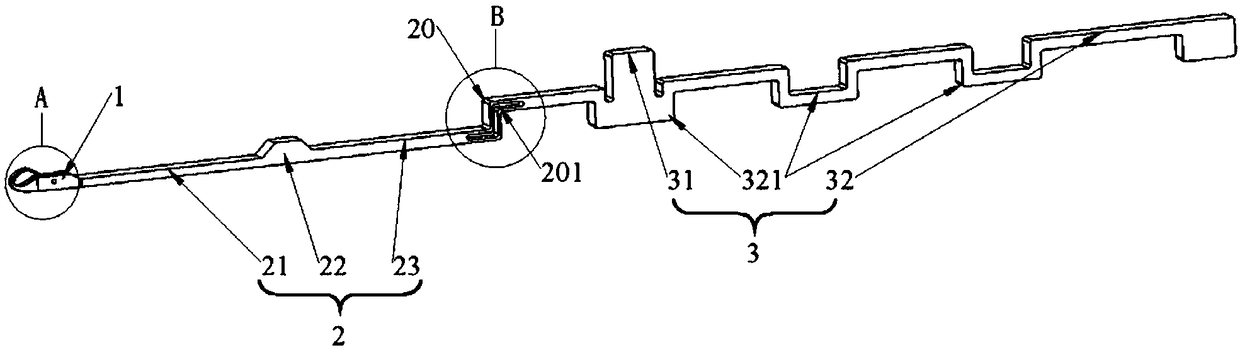

[0027] Such as figure 1 , figure 2 and Figure 5 As shown, a knitting needle for knitting provided in Embodiment 1 includes a needle head 1, a needle bar 2 and a stitch 3, the needle head 1 is arranged at the front end of the needle bar 2, and the stitch 3 is arranged at the rear end of the needle bar 2, The needle head 1 comprises a needle hook 11, a needle latch 12, a tongue groove 13 and a pin shaft 14, the tongue groove 13 is provided on the needle hook 11, and the needle latch 12 is swingably supported in the notch of the tongue groove 13 by the pin shaft 14, and the needle hook The free front end of the needle hook 11 is bent to form a hook point 111, and the cross-sectional area of the rear end of the needle hook 11 gradually increases in the radial direction until it is integrally formed with the front end of the needle bar 2 to form a needle hook transition end 112, and the needle hook transition end 112 is provided with a The tongue groove 13, the inner wall of ...

Embodiment 2

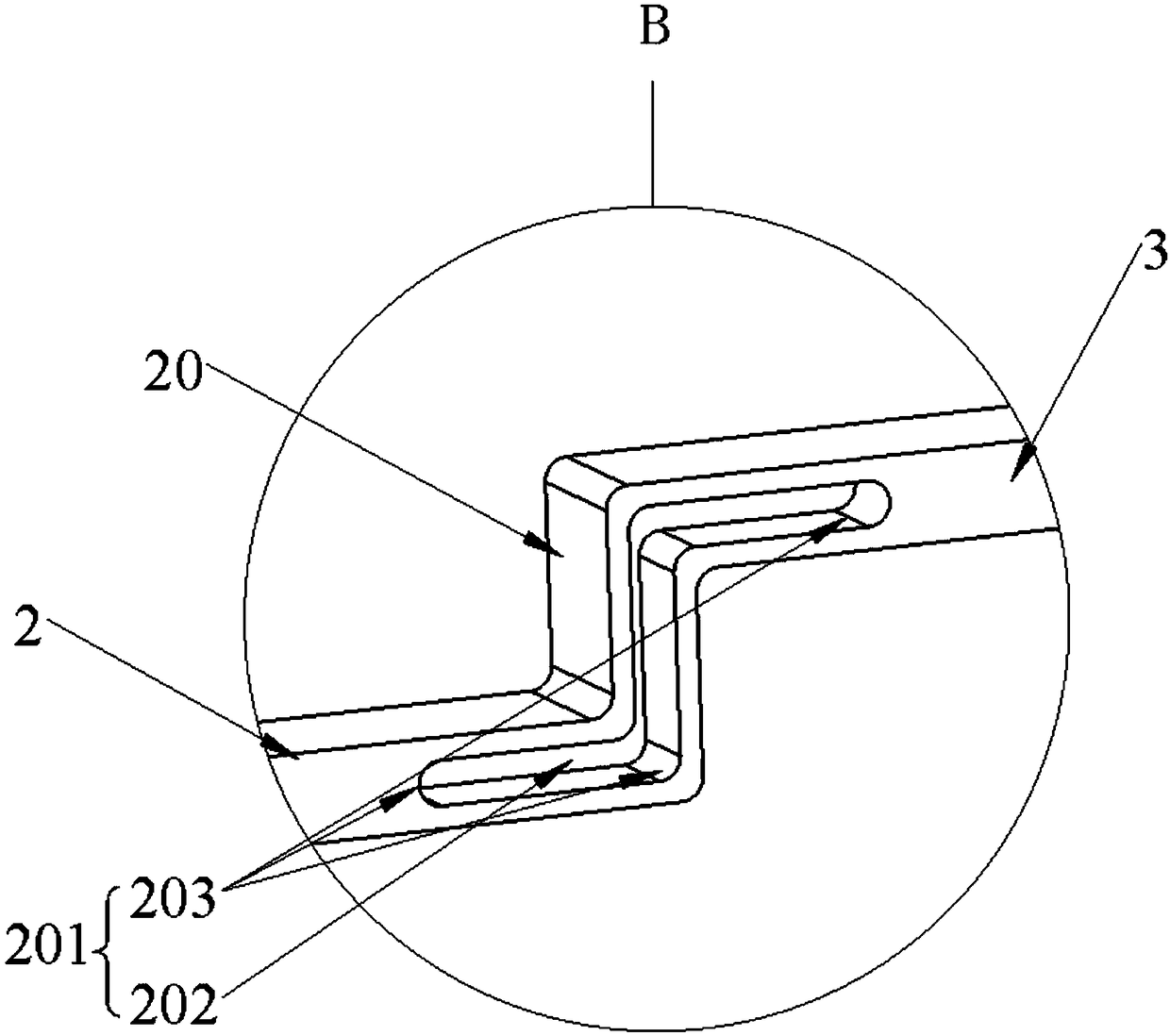

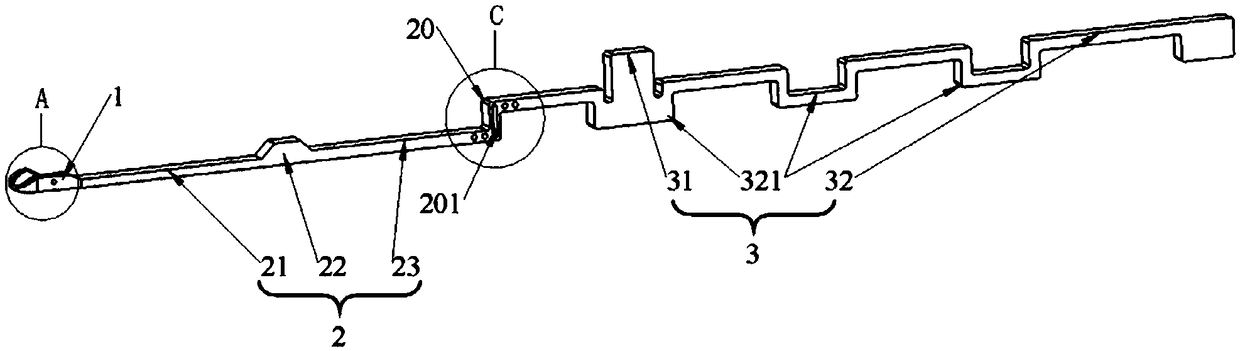

[0035] Such as image 3 , Figure 4 and Figure 5 As shown, in the knitting needle provided in the second embodiment, the connecting position between the needle bar 2 and the stitch 3 forms a transitional stepped foot 20 , and a notch 201 is provided on the stepped foot 20 . The notch 201 includes a straight groove 204 and a plurality of circular grooves 205. The straight groove 204 is set at the longitudinal corner position of the step foot 20, and the plurality of circular grooves 205 are evenly distributed on both sides of the straight groove 204. The groove diameter of the straight groove 204 is the same as the circle. The groove diameters of the grooves 205 are the same. In order to improve the stability of the knitting needles, reduce the shock type loads on the knitting needles and reduce the tendency of the knitting needles to be damaged. Further, since the straight grooves 204 and the plurality of circular grooves 205 have cavities, they can block the propagation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com