Device and method for feeding yarn

A yarn feeding device and yarn feeding technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve problems such as defects and yarn hooking, and achieve the effect of maintaining a smooth touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

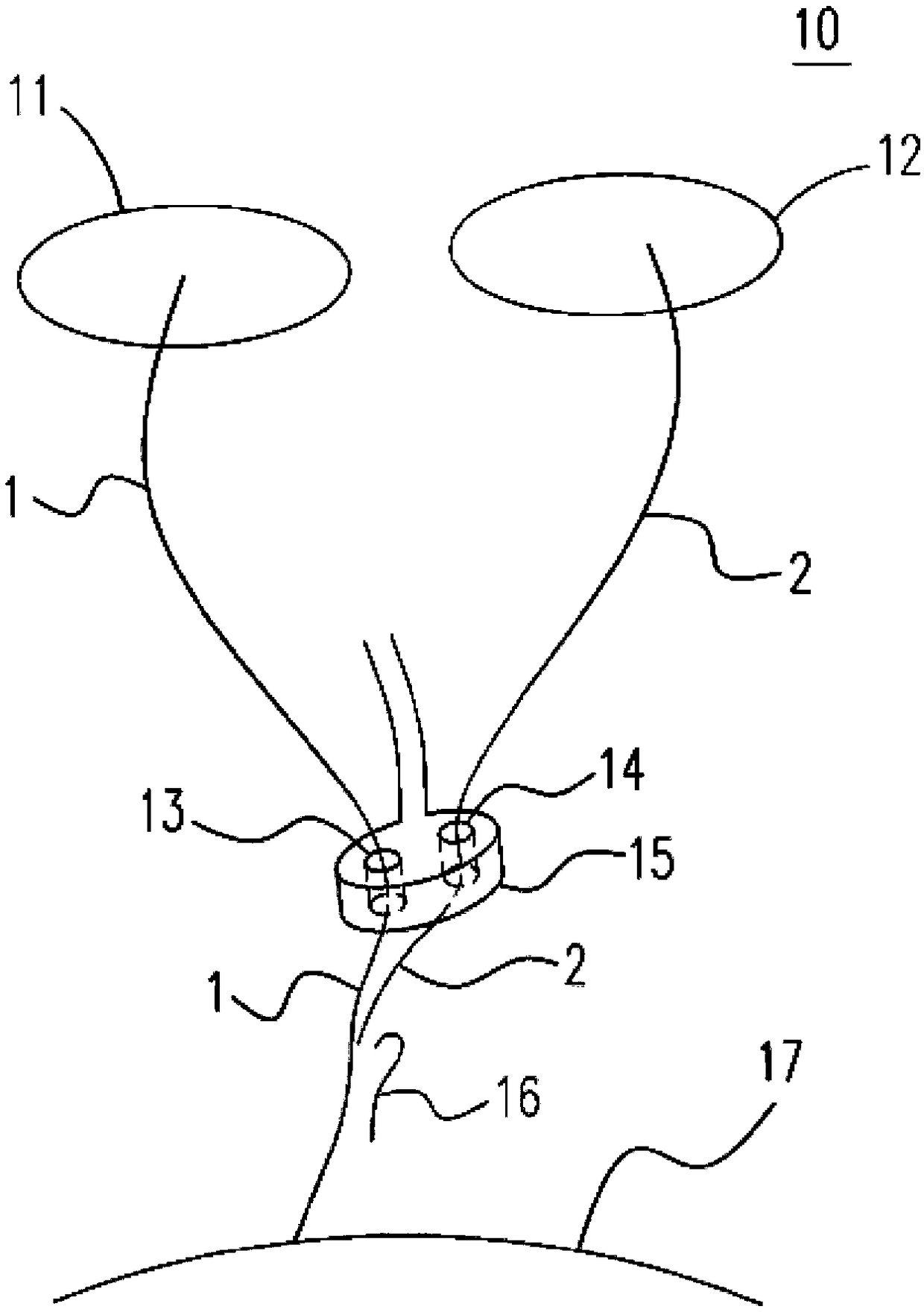

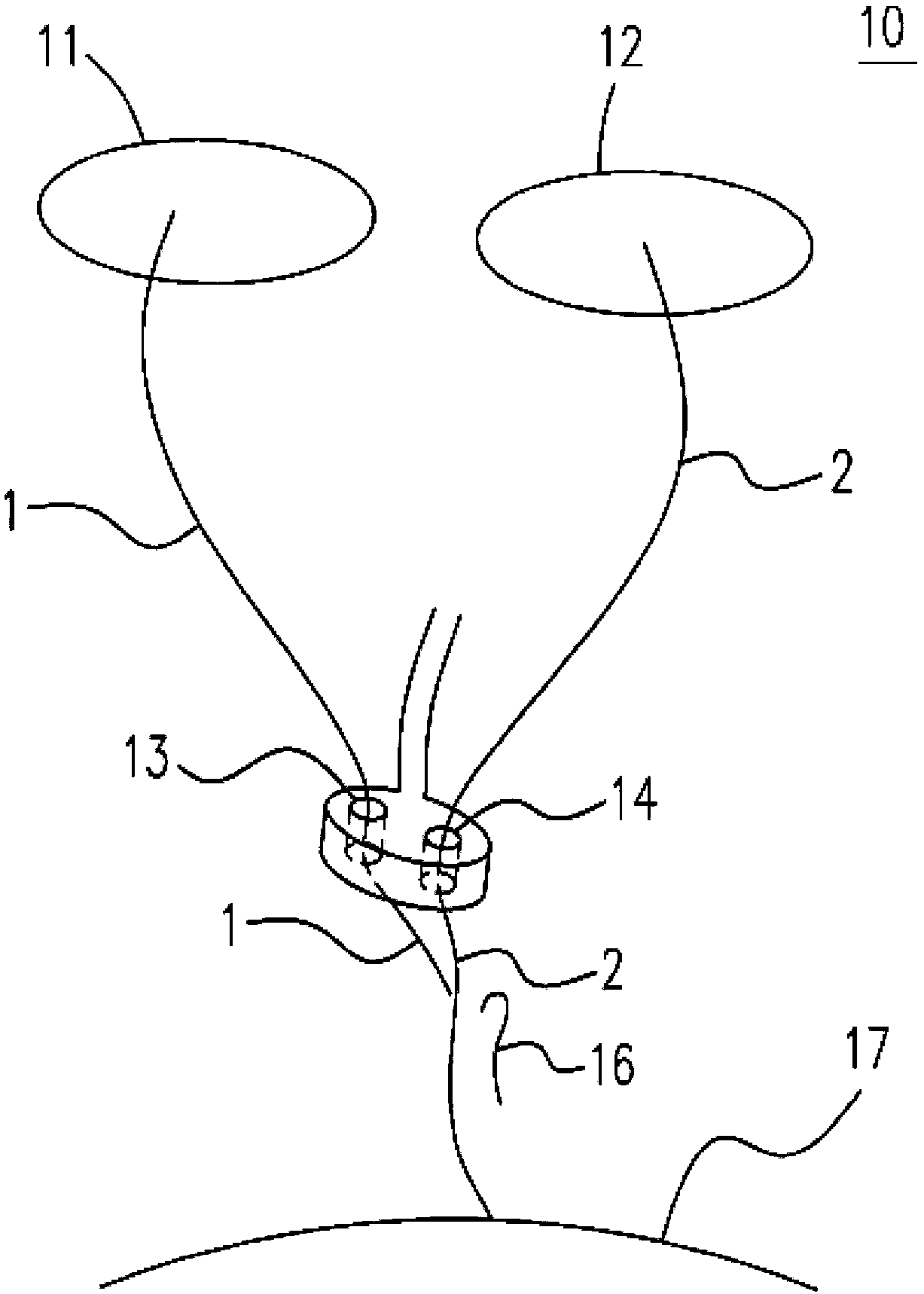

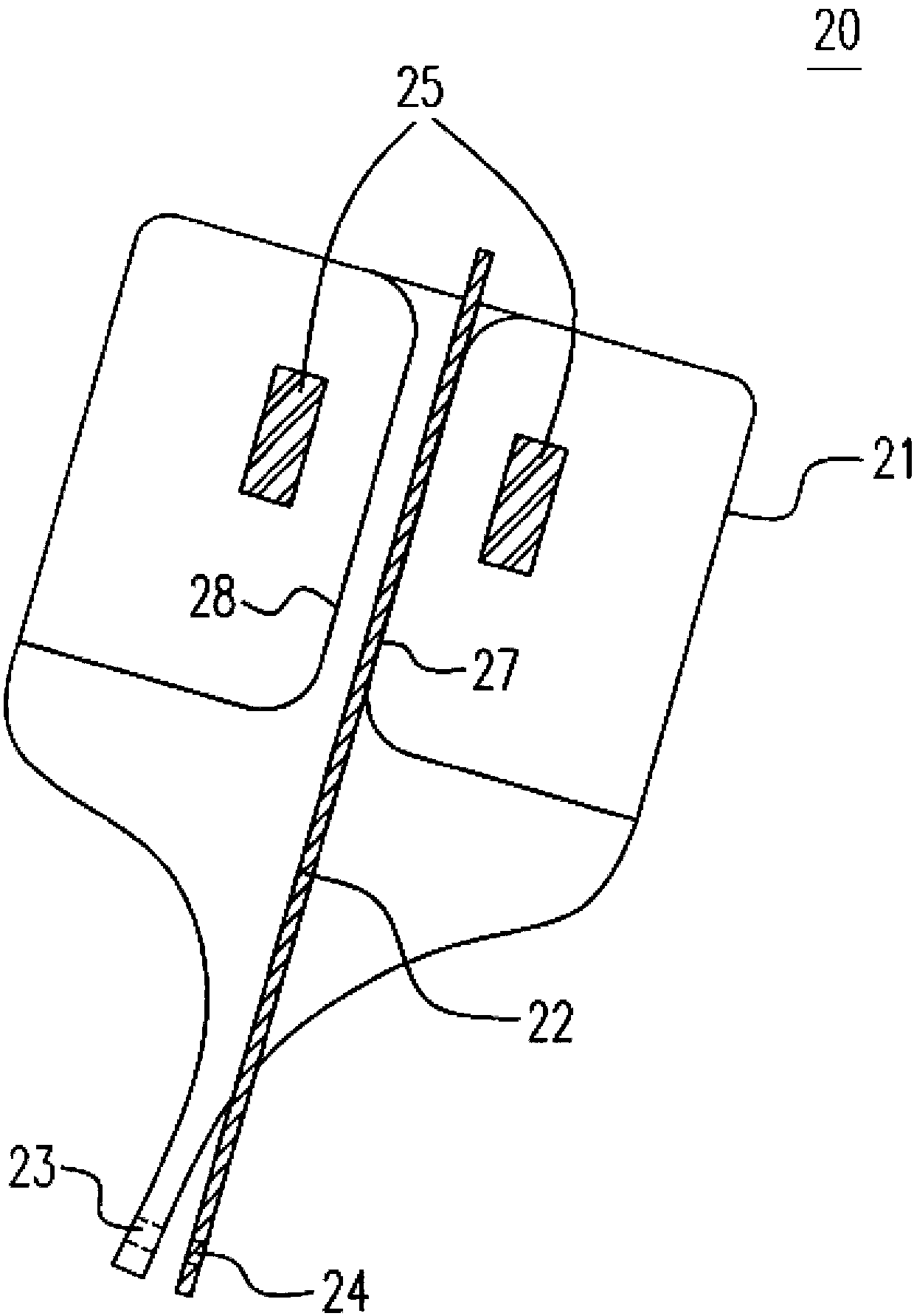

[0029] 1. A yarn feeding device for feeding a first yarn and a second yarn to a circular knitting needle, comprising:

[0030] a body having a first restricting portion and a second restricting portion; and

[0031] A yarn feeding rod is arranged on the body and has a first yarn hole for guiding the first yarn and a second yarn hole for guiding the second yarn respectively, wherein the first restricting part and the second restricting portion respectively cause the yarn feeding rod to be located at a first yarn feeding position and a second yarn feeding position, so that the circular knitting needle is under a specific time due to the yarn feeding rod, according to the One of the first and the second yarn feeding positions determines a knitting position of the first and second yarns.

[0032] 2. The device of embodiment 1, wherein:

[0033] When the yarn feeding rod is located at the first yarn feeding position, a first relative position is formed between the first yarn hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com