High-value treatment method for recycling pig dung and urine

A treatment method and resource-based technology, which is applied in the field of pig manure and urine treatment, can solve the problems of poor heat preservation effect, large carbon emissions, and accumulation, so as to reduce the number of excrement cleaning, reduce labor intensity, and improve the living environment. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

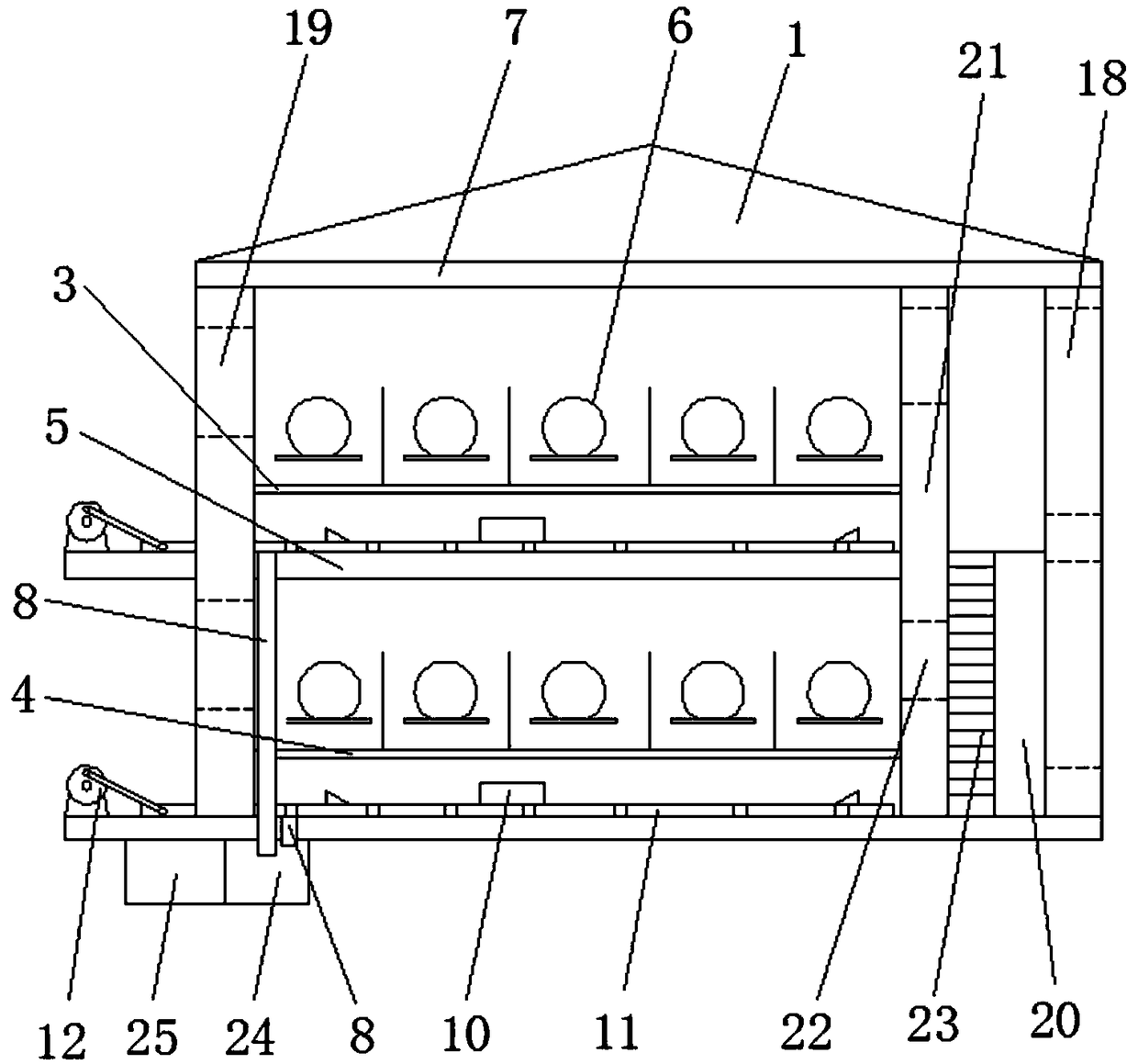

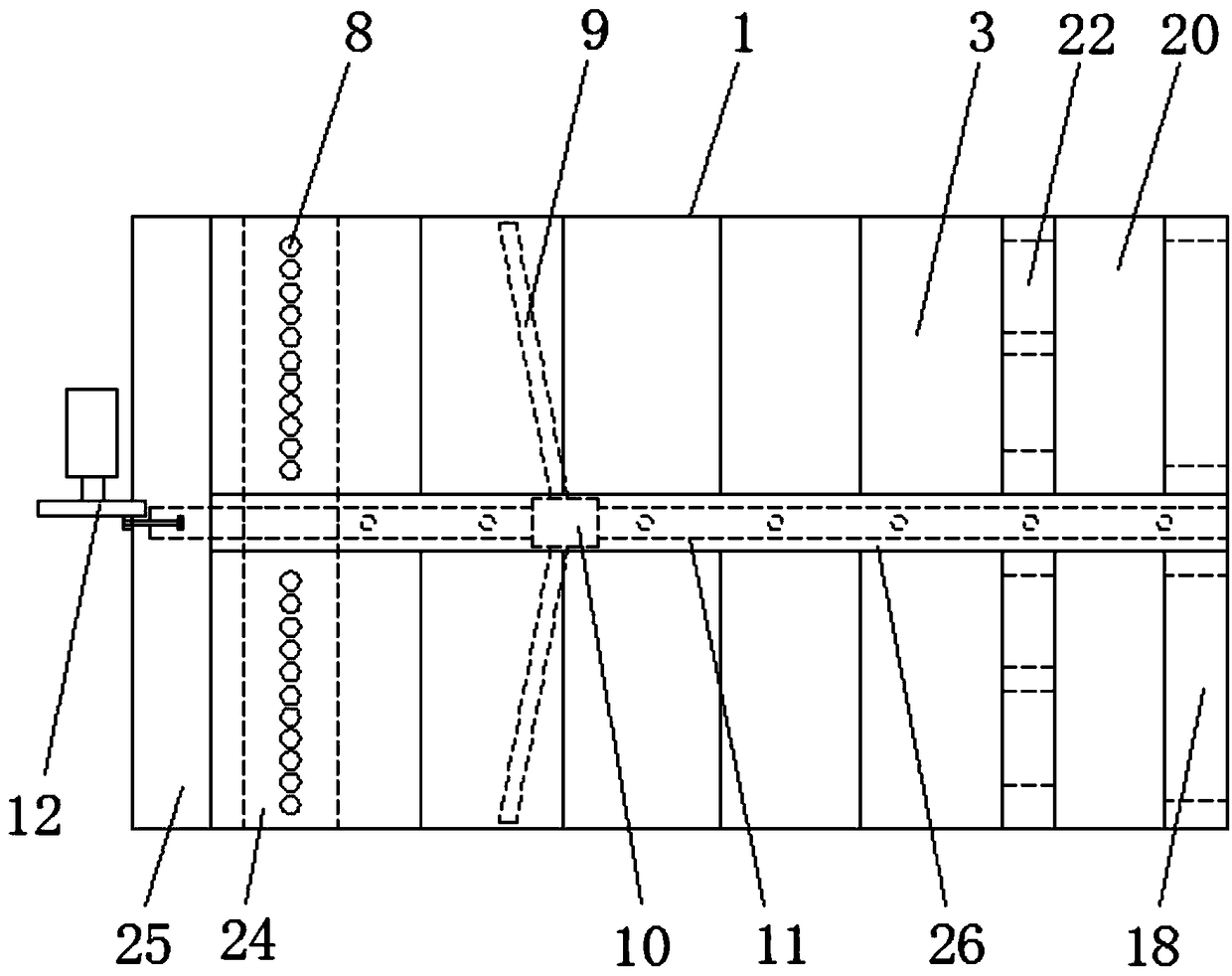

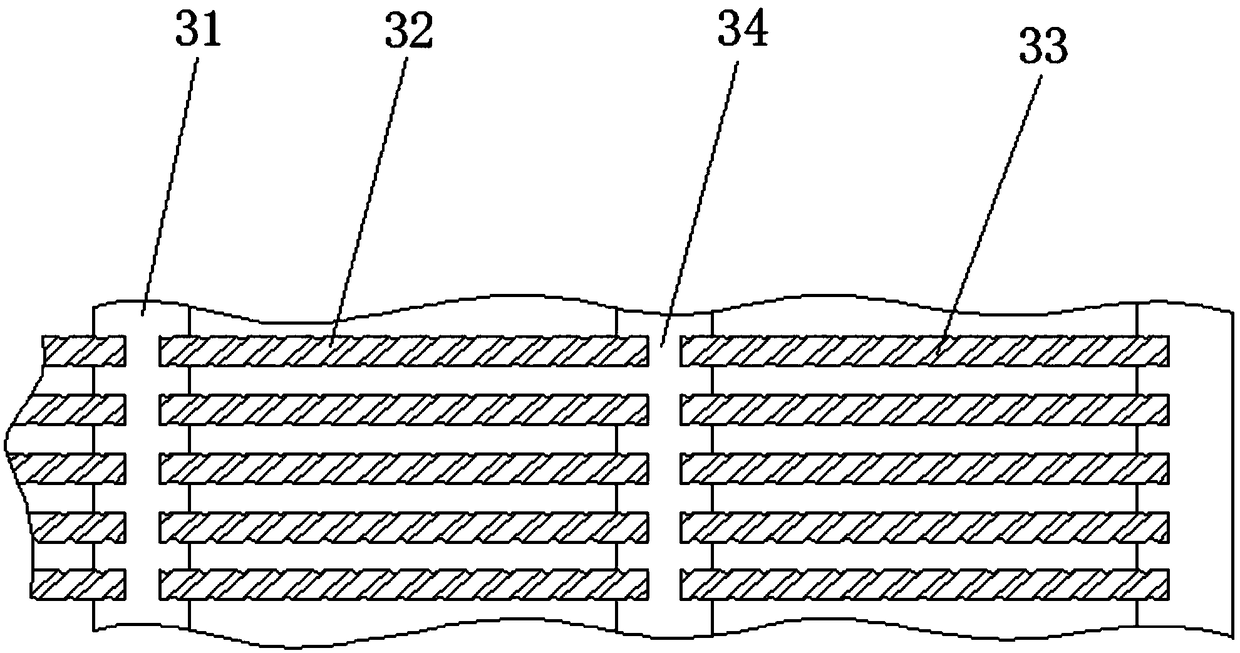

[0038] Step 1: The pigs are raised on the upper raised net bed 3 and the lower raised net bed 4 of the pig house, and the pigs are trained to defecate and urinate in a fixed position to ensure that the excrement accumulates and ferments on the floor below the raised net bed;

[0039] Step 2: Use the manure scraper under the elevated net bed to push the manure into the manure treatment tank, and add 1 kg of brown sugar per 10 tons of manure and 3 per 10 tons of manure in the manure treatment tank. After mixing for 0.5 hours, add strains per kilogram, suck and transport to the ectopic fermentation bed and add 12 tons of straw powder for every 10 tons of feces and urine to carry out mixed fermentation, mix and pile up, turn the pile 3 times every 5 days, and press Add 2 kg of added strains to every 10 tons of manure to get old manure with a water content of 25-35%;

[0040] Step 3: Add 1 ton of fresh manure to the old manure for every 10 tons of old manure, add 220 kilograms of s...

Embodiment 2

[0043] Step 1: The pigs are raised on the upper raised net bed 3 and the lower raised net bed 4 of the pig house, and the pigs are trained to defecate and urinate in a fixed position to ensure that the excrement accumulates and ferments on the floor below the raised net bed;

[0044] Step 2: Use the excrement scraper under the elevated net bed to push the excrement into the excrement treatment tank, and add 5 kg of brown sugar per 10 tons of excrement and 2 kg per 10 tons of excrement in the excrement treatment tank. After mixing for 1.5 hours, add strains in 1 kg, suck and transport to the ectopic fermentation bed and add 8 tons of straw powder for every 10 tons of manure and urine for mixed fermentation, mix and pile up, turn the pile once every 8 days, after 30 days, press Add 3 kg of added strains to every 10 tons of manure to get old manure with a water content of 25-35%;

[0045] Step 3: Add 4 tons of fresh manure to the old manure for every 10 tons of old manure, add 18...

Embodiment 3

[0048] Step 1: The pigs are raised on the upper elevated net bed 3 and the lower elevated net bed 4, and the pigs are trained to defecate and urinate in a fixed position to ensure that the excrement accumulates and ferments on the floor below the elevated net bed;

[0049] Step 2: Use the manure scraper under the elevated net bed to push the manure into the manure treatment tank, and add 3 kg of brown sugar per 10 tons of manure and 2.5 grams per 10 tons of manure in the manure treatment tank. After mixing for 1 hour, add strains per kilogram, and then suck them to the ectopic fermentation bed and add 10 tons of straw powder for every 10 tons of feces and urine to carry out mixed fermentation. Add 2.5 kg of added strains to 10 tons of feces and urine to obtain old feces with a water content of 25-35%;

[0050] Step 3: Add 2 tons of fresh manure to the old manure for every 10 tons of old manure, and add 200 kg of straw powder for every 10 tons of old manure to carry out seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com