Cam-lever-type automatic feeding device

A technology of automatic feeding and cam levers, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of inaccurate loading of workpieces to be processed, difficult workpiece driving loading, and complicated structure of feeding mechanism, etc., so as to facilitate manual operation The effects of debugging, continuous and stable feeding, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

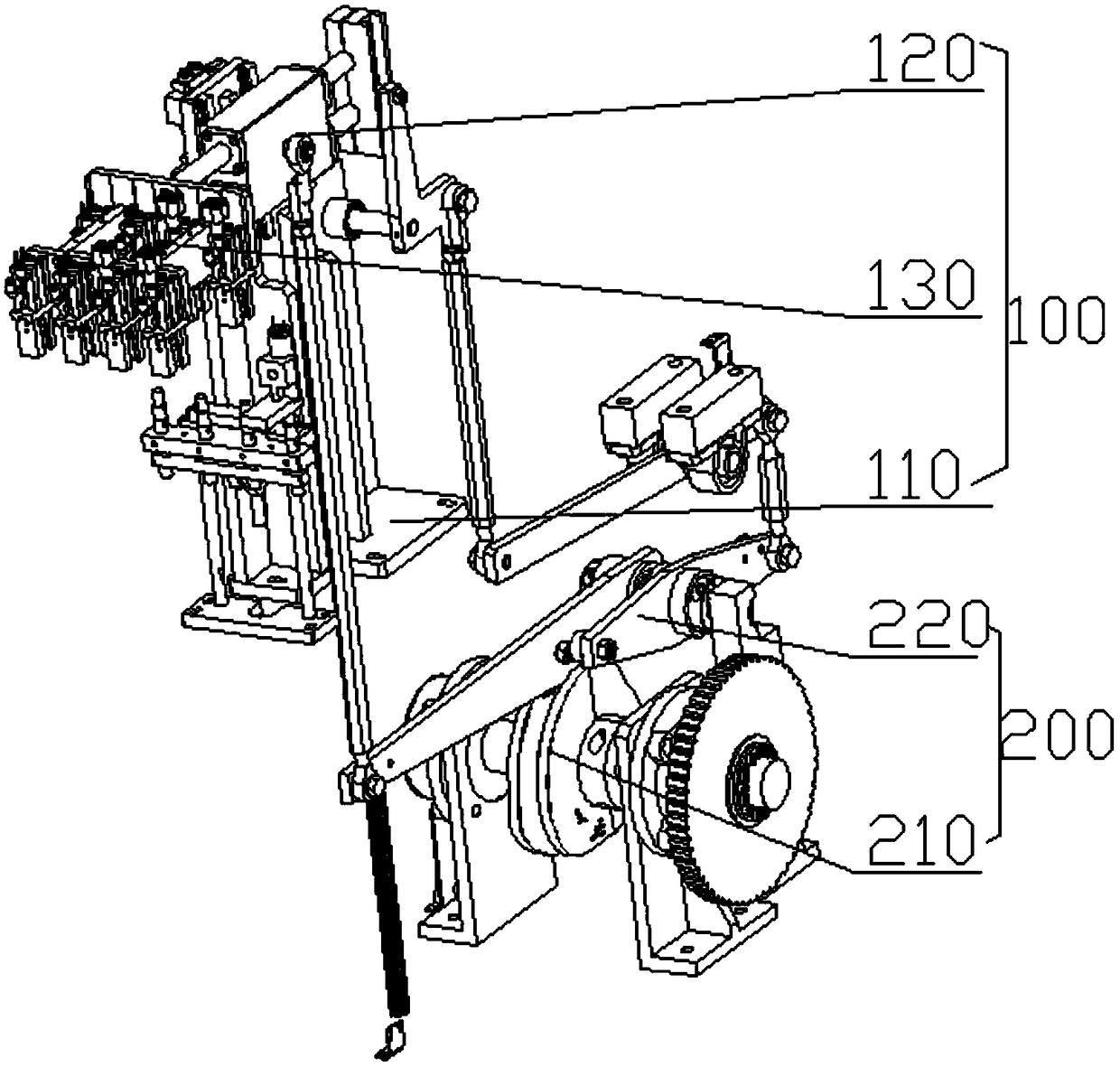

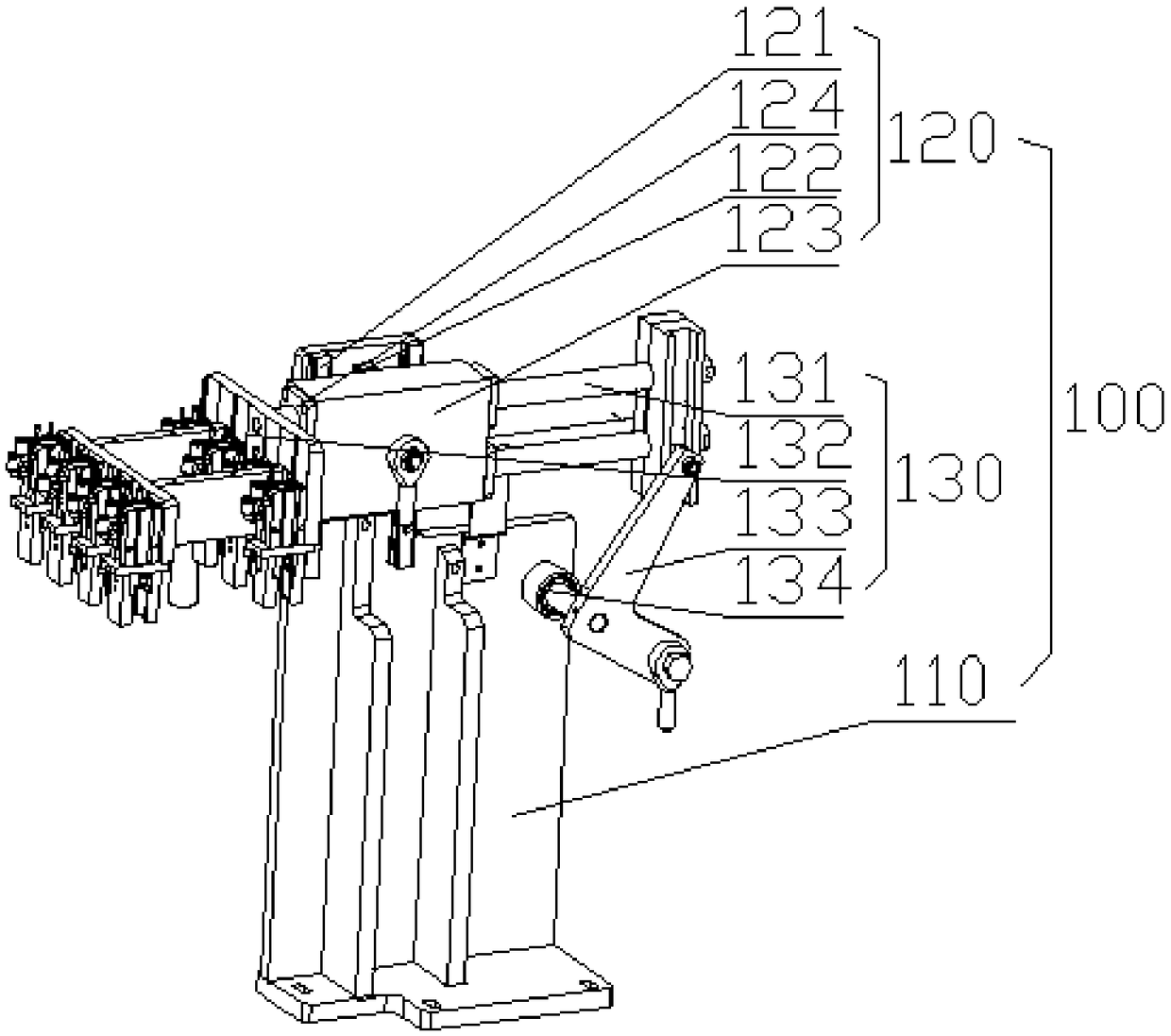

[0017] refer to figure 1 As shown, a cam lever type automatic feeding device has a frame (not shown in the figure) and a workbench (not shown in the figure) located on the frame; the workbench (not shown in the figure) Excavation) Excavate the first through hole (not shown in the figure) and the second through hole (not shown in the figure) that run through it, and its upper and lower ends are respectively provided with a feeding mechanism 100 and a power mechanism 200, The feeding mechanism 100 is installed on the table of the workbench (not shown in the figure), the power mechanism 200 is installed on the frame (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com