A shopping mall logistics transporting trolley

A logistics handling and trolley technology, applied in trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of different sizes and weights of goods, inability to adapt to goods handling, and affect the efficiency of handling, etc., to achieve a simple and reliable structure. Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

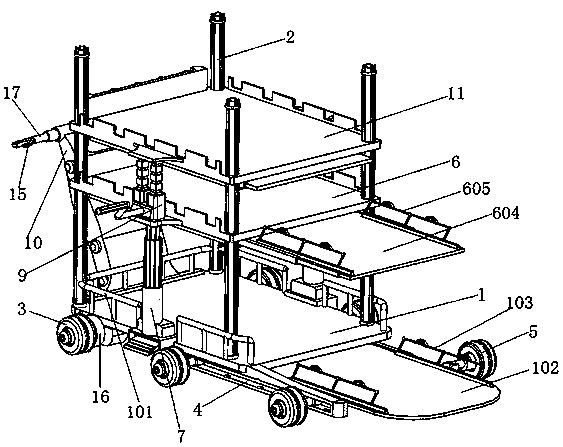

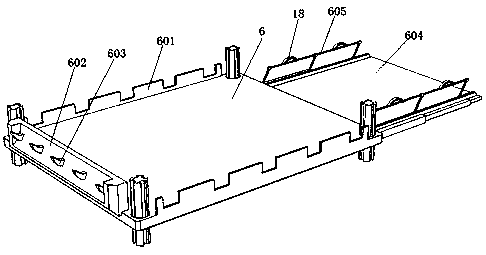

[0030] Embodiment 1: as Figure 1-6 As shown, the logistics handling trolley of this shopping mall includes a base plate layer 1, a railing 101, a bottom splint 102, a bottom splint stacked fence 103, a sleeve rod 2, a fixed wheel 3, a chute 4, a moving wheel 5, a moving plate layer I 6, a guard Frame 601, tail frame 602, moving splint 604, moving splint stacking frame 605, 2 pedal jacks 7, ribs 8, 2 hand jacks 9, armrest frame 10, moving plate II 11, armrest handle 17; , the floor layer 1 is provided with a railing 101, the bottom of the floor layer 1 is provided with a pull-out bottom plywood 102, the bottom plywood 102 is provided with a foldable bottom plywood stack railing 103, and more than 4 sets of rods 2 are fixed on the bottom plate On layer 1, two chutes 4 are respectively fixed on both sides of the front end of the floor layer 1 and outside the bottom plywood 102, two fixed wheels 3 are arranged on the rear end of the bottom of the floor layer 1, and the other two ...

Embodiment 2

[0031] Embodiment 2: The structure of the device of this embodiment is the same as that of Embodiment 1, the difference is that the device is provided with 3 layers of moving plates, the bottom of the floor layer 1 is provided with a chute, and the bottom splint 102 is arranged in the chute by the slide rail on it and Move along the chute; the bottom of the moving plate I6 or II11 is provided with a chute, and the moving splint 604 is set in the chute through the slide rail on it and moves along the chute.

Embodiment 3

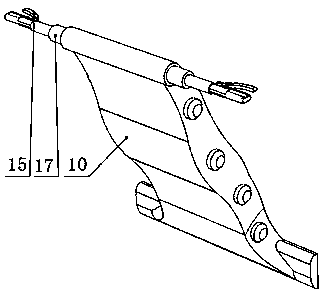

[0032] Embodiment 3: The structure of the device of this embodiment is the same as that of Embodiment 1, the difference is that: the shopping mall logistics handling trolley also includes a hand brake device, and the hand brake device includes a brake handle 15 and a drum brake 16, and the handrail handle is provided with a brake handle 15 and a drum brake 16 It is mounted on one side of the two fixed wheels 3; the brake handle 15 is connected with the drum brake 16 through the brake line and the brake control is realized by means of braking; the upper surfaces of the bottom layer 1, the moving layer I6, and the moving layer II11 are not smooth .

[0033] When the device is working: put the shopping mall logistics trolley flat on the ground, put the goods on the bottom layer 1, if the length of the goods is large, pull out the bottom splint 102 from the bottom of the bottom layer 1, and stack the bottom splint The frame 103 is opened to prevent the goods from slipping out, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com