Robot fixing device

A fixed device and robot technology, applied in the field of car body manufacturing, can solve the problems of increased maintenance time and difficulty in operation, no site layout for supporting facilities, difficulty in operation, etc., and achieves reasonable location and space layout, high space utilization, and high flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

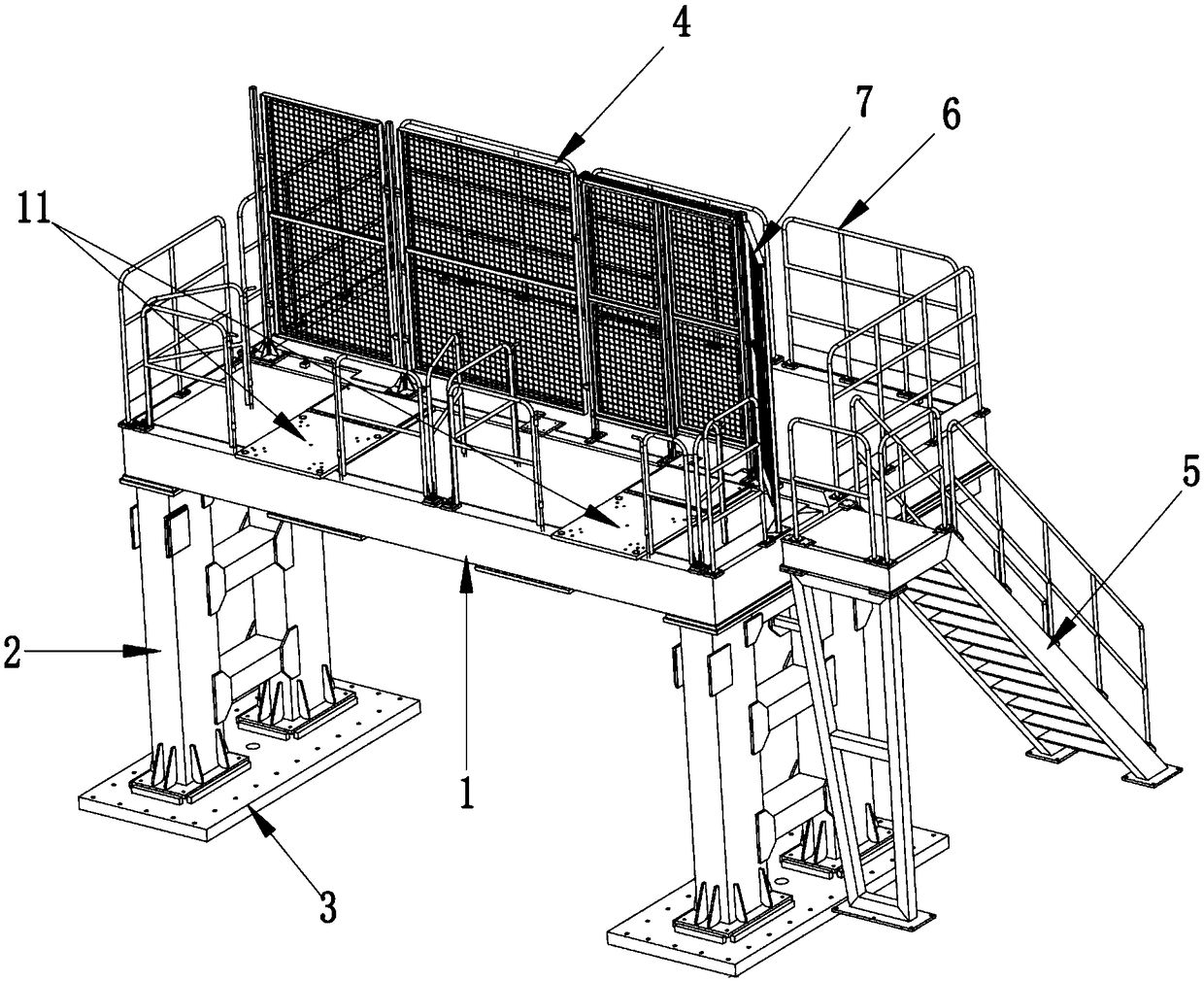

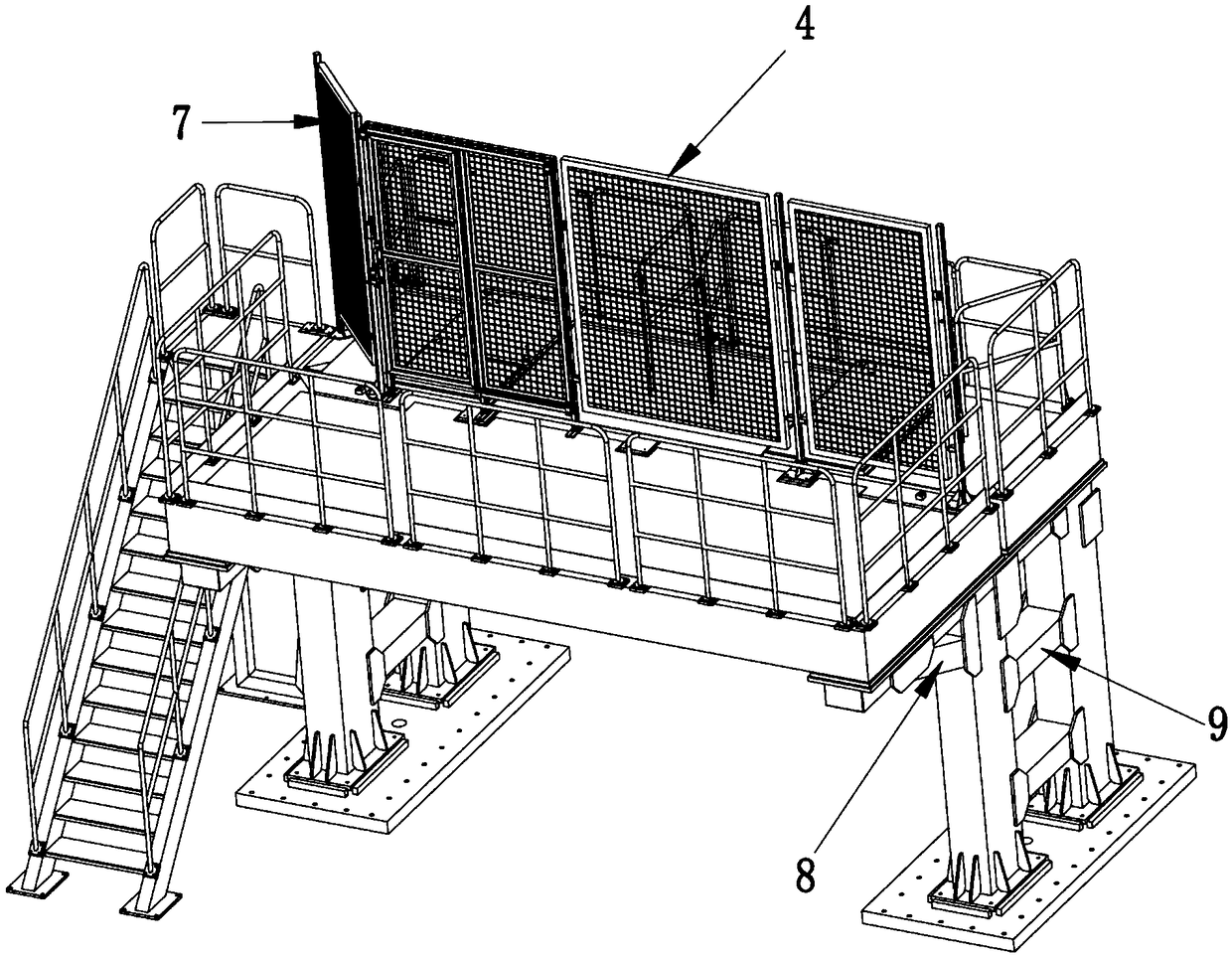

[0016] Such as figure 1 and figure 2 As shown, the present invention discloses a robot fixing device, which includes a support platform 1, a foot 2, an embedded board 3, a guard net 4 and an inclined ladder 5, and the lower end of the foot 2 is fixedly connected to the embedded board 3, so that The pre-embedded plate 3 is a steel plate, which is pre-embedded in the foundation before the ground of the production site is solidified, and then strengthened and connected by expansion bolts after pre-embedding, which can greatly enhance the bearing capacity. The lower end of the support platform 1 is fixed to the upper end of the support foot 2 connected, the inclined ladder 5 is arranged on one side of the supporting platform 1 for operators to board the supporting platform 1, and the protective net 4 is arranged on the upper end of the supporting platform 1 and separates the upper end of the supporting platform 1 into Robot installation area and manual operation area, described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com