Automatic pipe grooving machine

A grooving machine and pipe material technology, which is applied in metal processing machinery parts, clamping, support, etc., can solve the problems of poor grooving accuracy and low grooving efficiency, and achieve improved production efficiency, improved consistency and precision, and Effect of Medium Precision Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the description of these embodiments is used to help understand the present invention, but does not constitute a limitation to the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

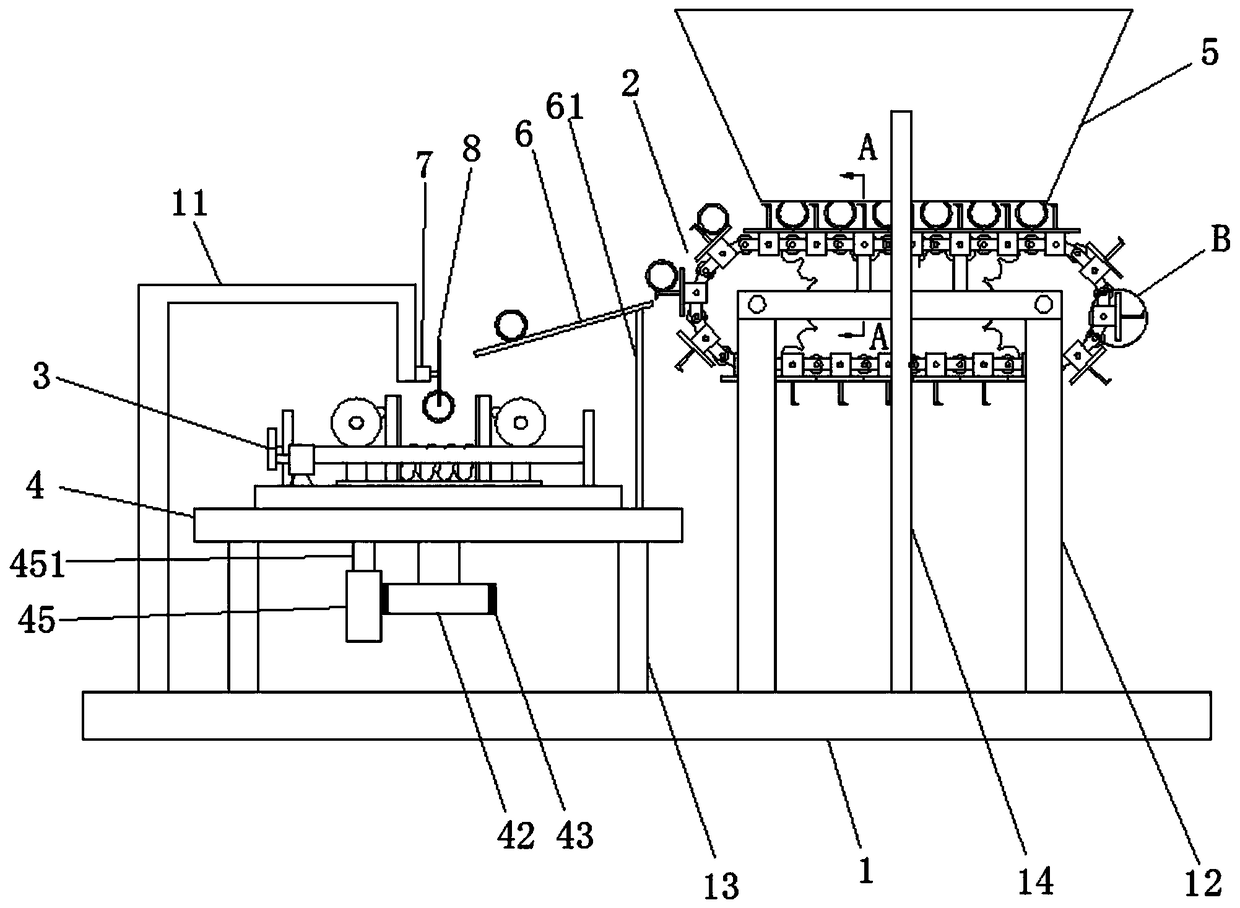

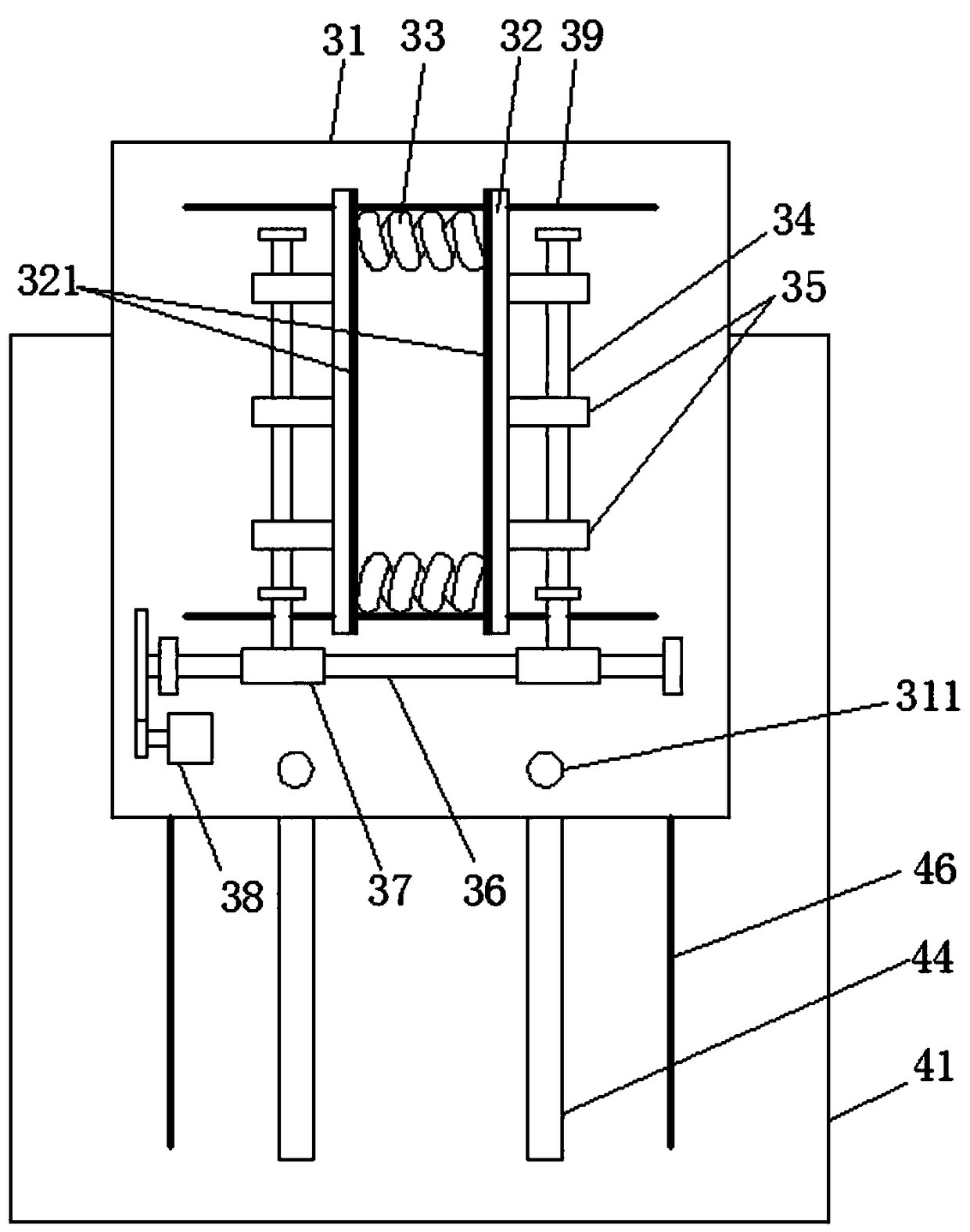

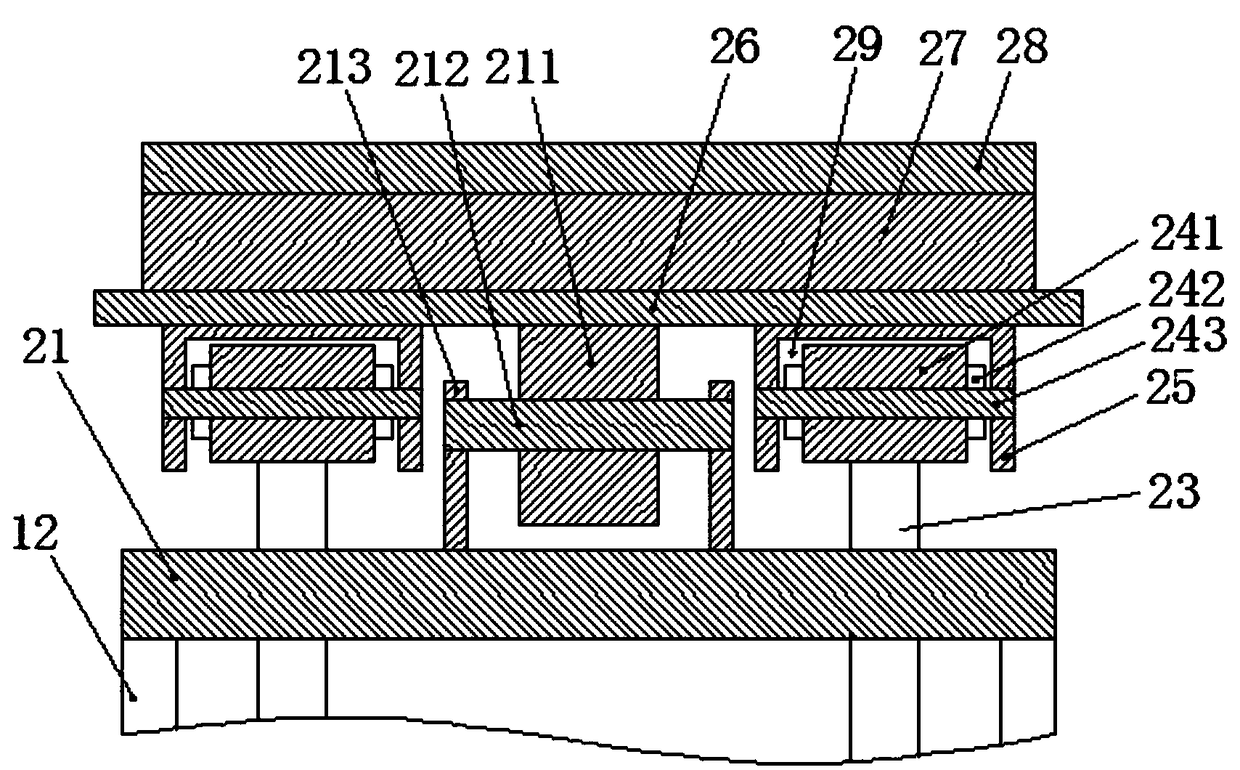

[0018] Such as figure 1 As shown, an automated pipe grooving machine includes a frame body 1, a storage bin 5 for storing pipes, a feeding device 2 for feeding, a clamping device 3 for clamping the pipe, and a conveying and clamping device. The transfer device 4 of the device 3, the grooving cutter wheel 8 for grooving, the power motor 7 that drives the grooving cutter wheel 8 to rotate, and the control device, the feeding device 2 is connected to the frame 1 through the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com