construction waste crusher

A technology for construction waste and crushers, which is applied in solid separation, chemical instruments and methods, and grain processing, etc. It can solve the problems of screen mesh blockage, reduced screening efficiency, and enhanced adhesion, so as to prevent blockage and improve The effect of screening efficiency and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

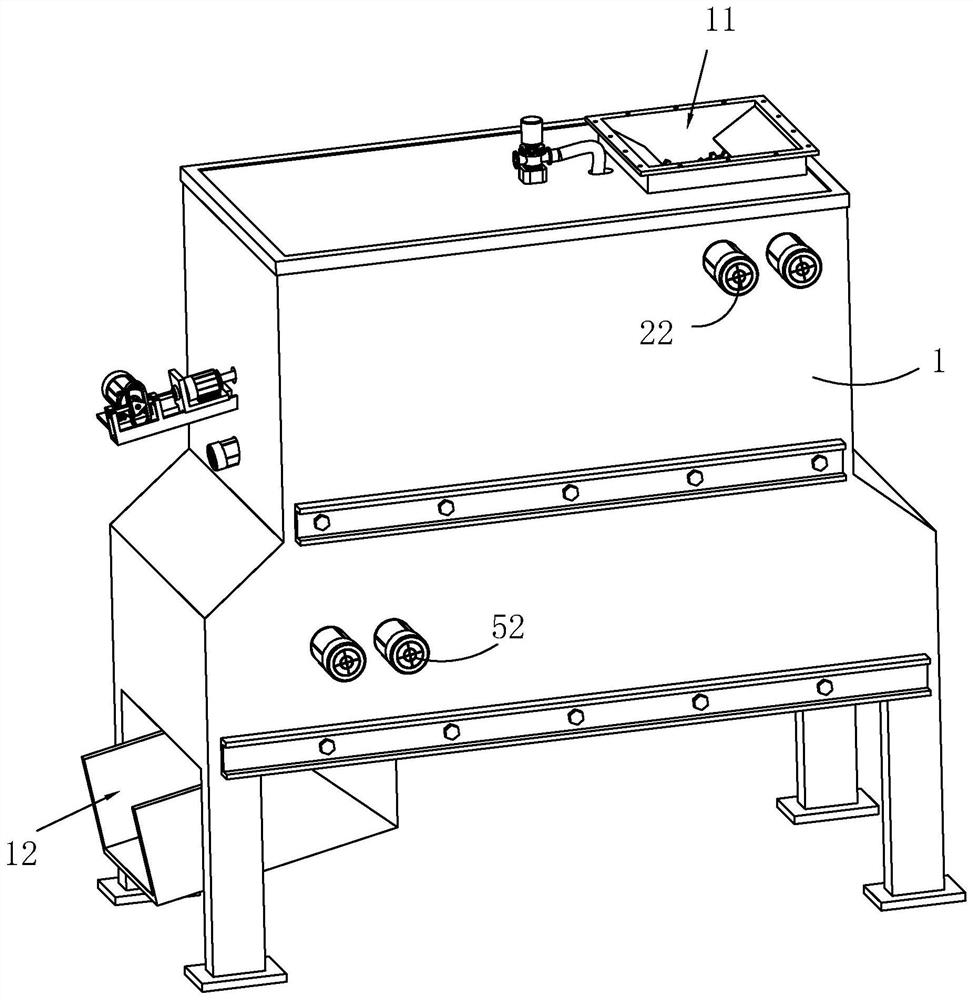

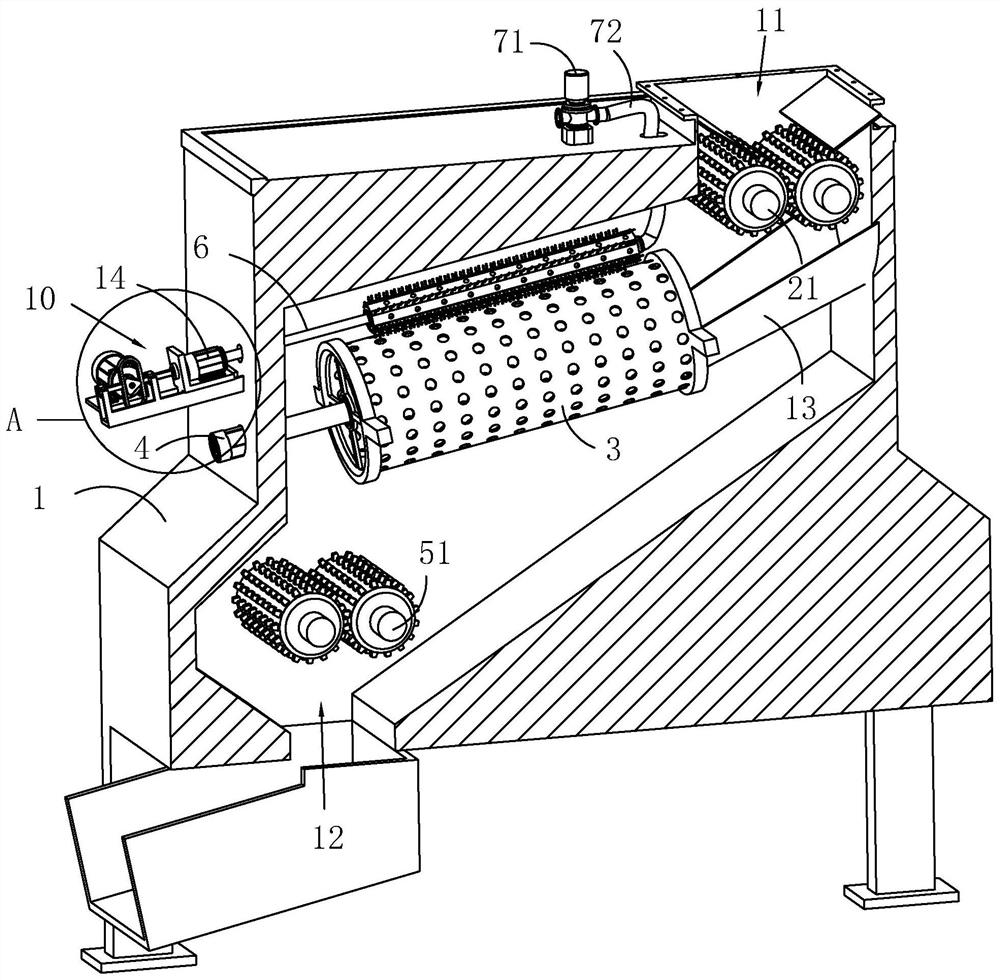

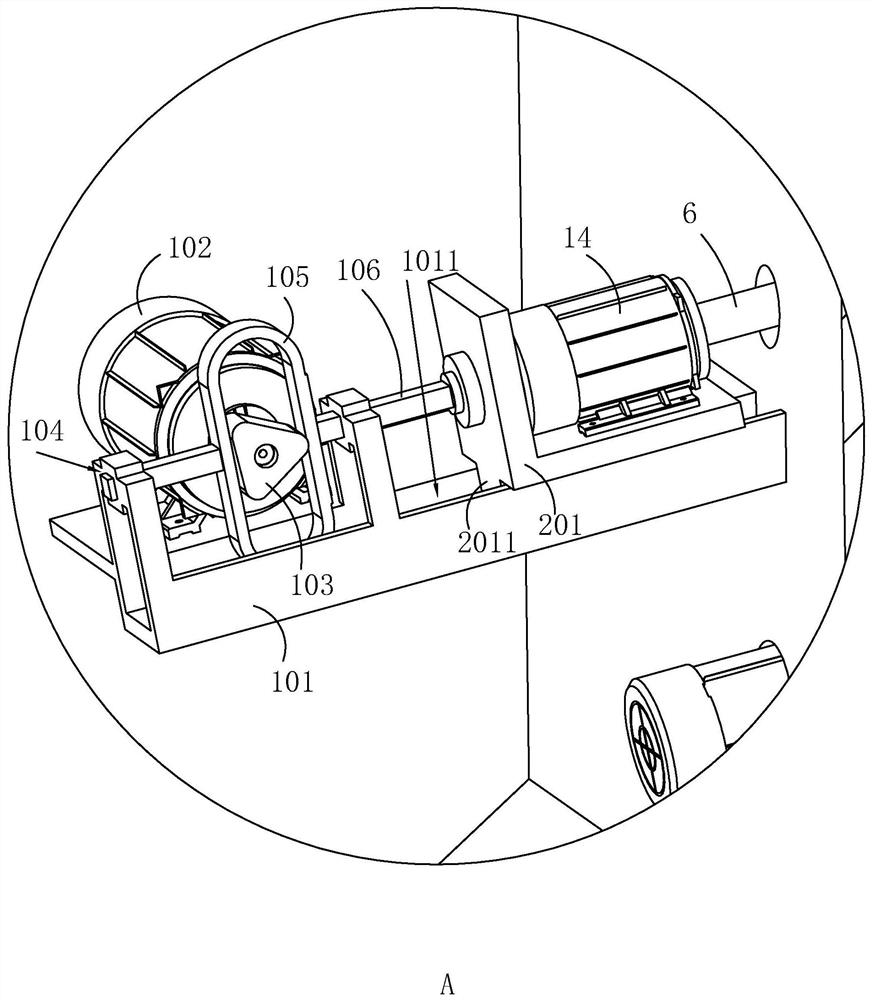

[0039] Such as figure 1 , 2 As shown, a construction waste crusher includes a housing 1, a feed hopper 11 is provided on the upper end of the housing 1, and a first crushing assembly is installed at the discharge port of the feed hopper 11, and the first crushing assembly includes a rotating Two first crushing rollers 21 arranged in the casing 1 and a first drive motor 22 fixedly arranged on the casing 1 for driving the rotation of the first crushing rollers 21, and a screening cylinder 3 is installed in the casing 1 for rotation, The screening cylinder 3 is made of polyurethane, and the housing 1 is fixedly provided with a first motor 4 for driving the rotation of the screening cylinder 3; a second crushing assembly is arranged at the outlet of the screening cylinder 3, and the second crushing assembly includes Rotate the two second crushing rollers 51 arranged in the casing 1 and the second drive motor 52 fixedly arranged on the casing 1 for driving the rotation of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com