Mud scraping device

A scraper and driving device technology, applied in chemical instruments and methods, separation methods, precipitation separation, etc., can solve problems such as resistance, limited cleaning effect, inconvenience, etc., and achieve lower use costs, lower power burdens, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the mud scraping device proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. The details are as follows.

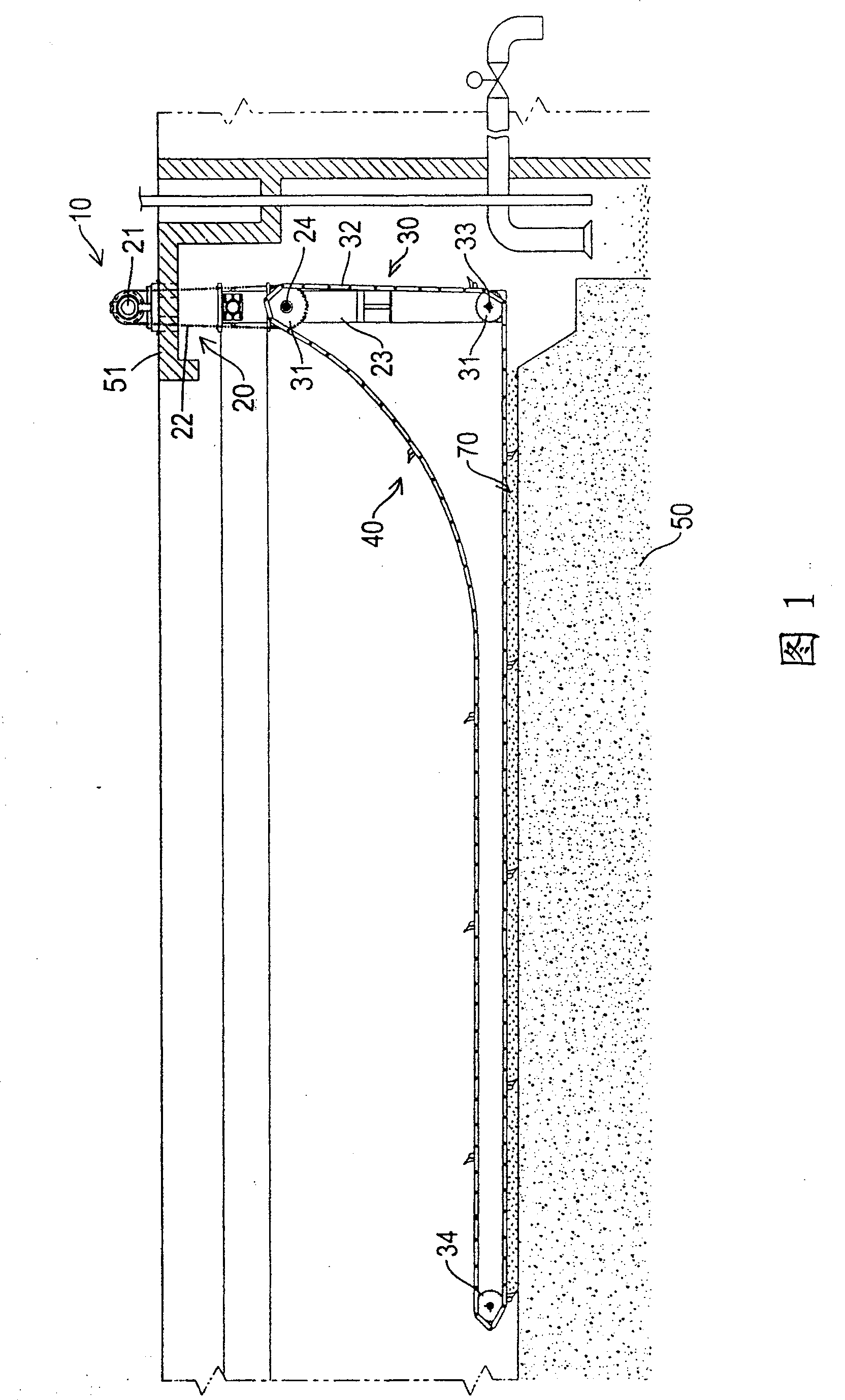

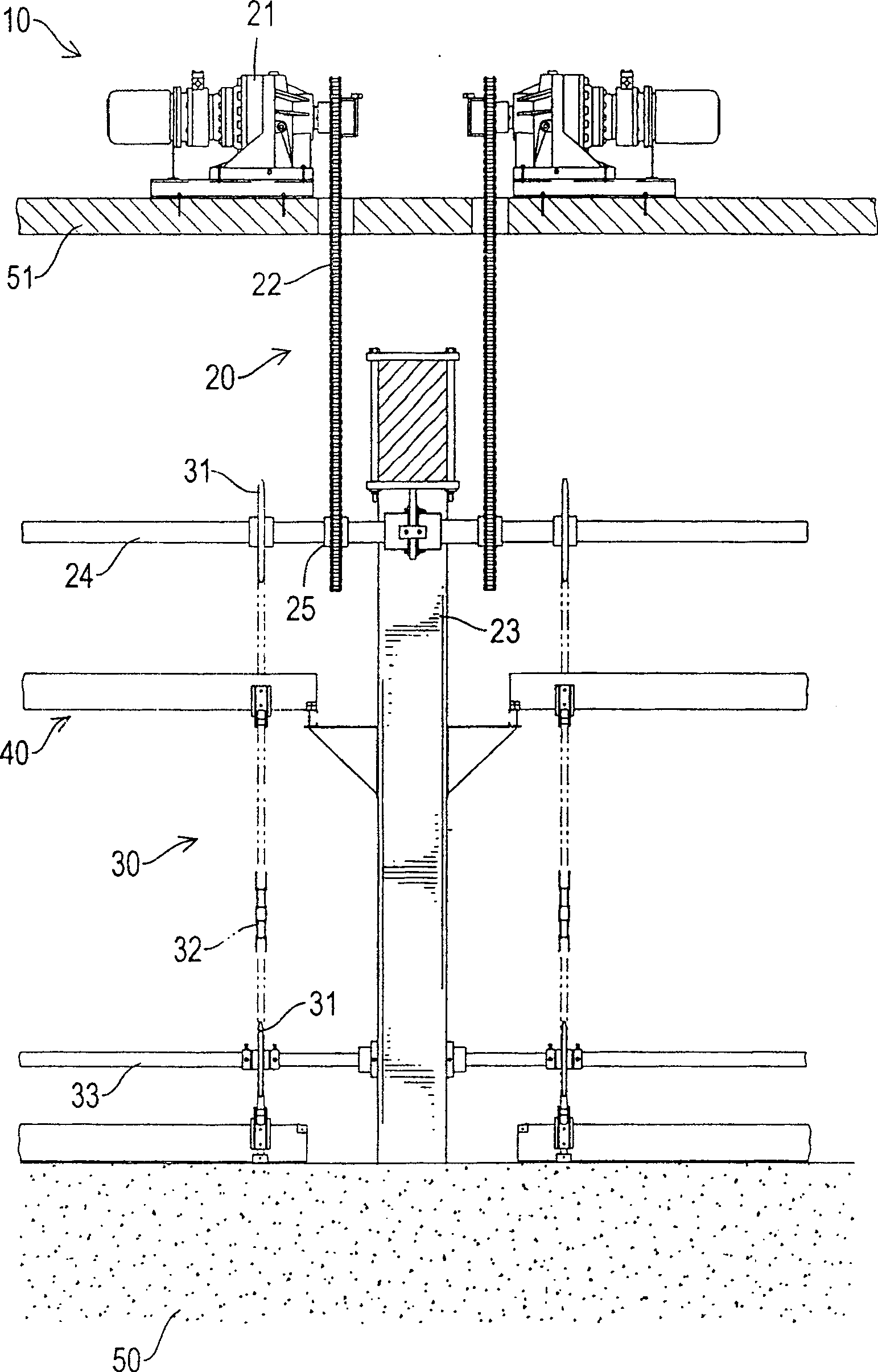

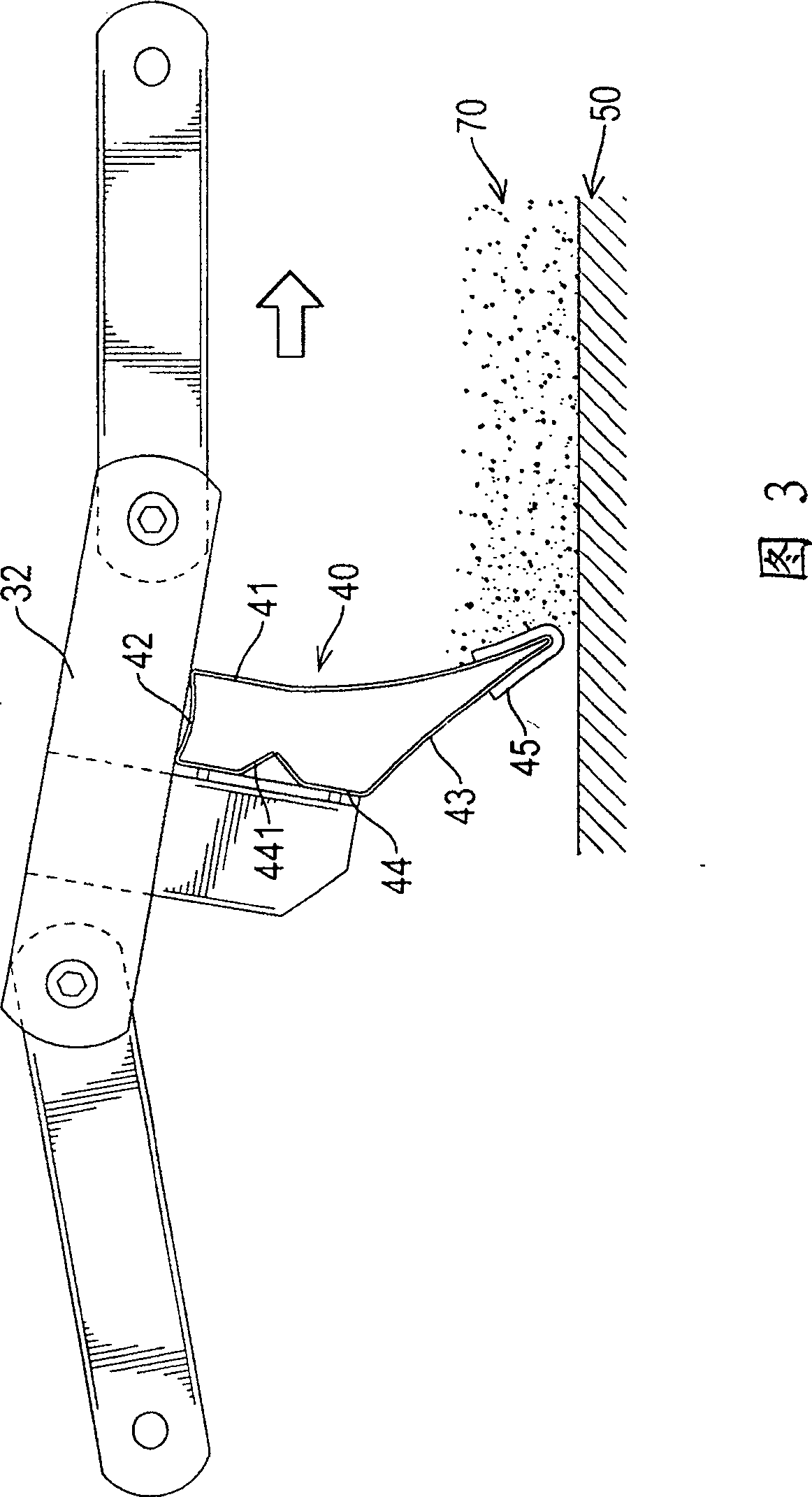

[0049] The present invention mainly provides a mud scraping device 10, please refer to Fig. 1 to figure 2 As can be seen from the figure, the mud scraping device 10 of the present invention is combined with a water tank 50, which includes:

[0050] A driving device 20, the driving device 20 includes a driving motor 21, a driving chain 22, a support column 23, a main shaft 24 and a transmission sprocket 25, wherein the driving motor 21 is installed by a supporting plate 51 Located above the water tank 50, the drive chain 22 is combined with the drive motor 21 and extends in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com