Air-oxygen mixed gas path design and respirator with gas path

A technology of oxygen mixing and gas mixing, applied in respirator and other directions, can solve problems such as high accuracy and oxygen concentration error, and achieve the effect of precise control of concentration and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

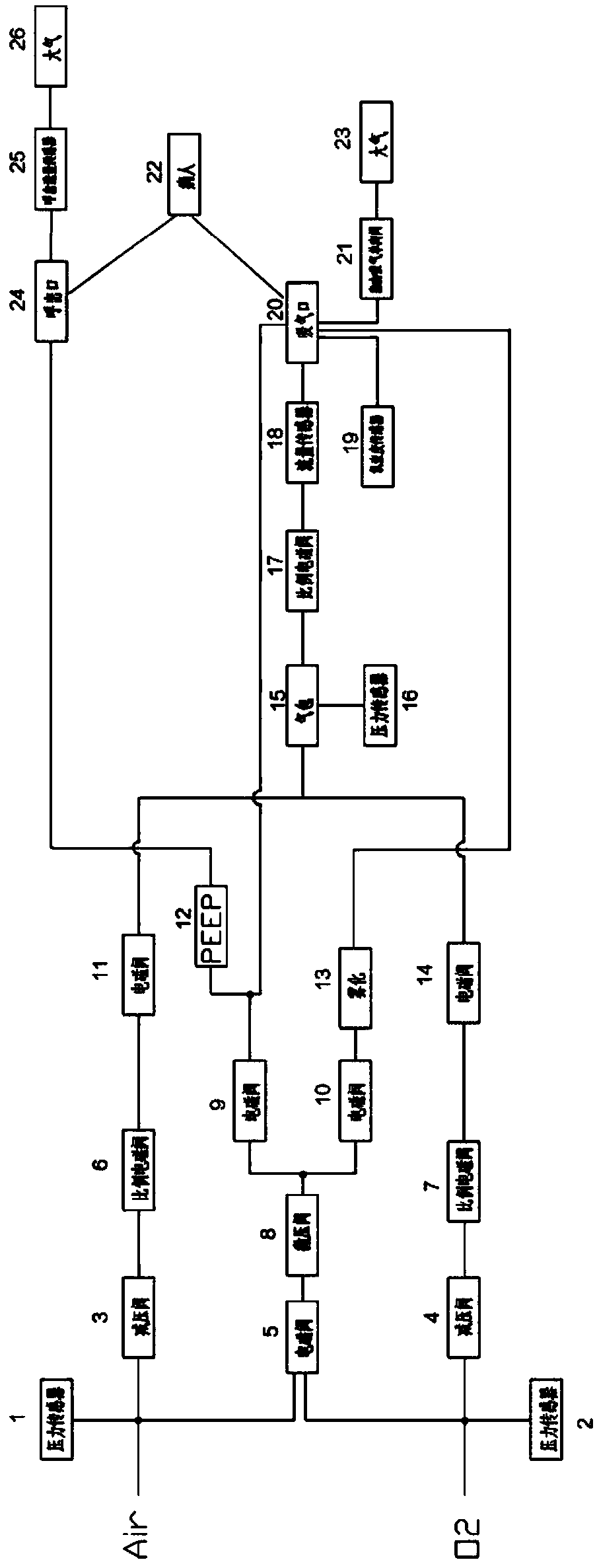

[0017] see figure 1 , it is given that the hollow oxygen mixed gas path design of the present invention has an air path, an oxygen path, and a mixing path. The air path includes an air inlet, a pressure sensor 1, a pressure reducing valve 3, a proportional solenoid valve 6, and a solenoid valve 11. The oxygen circuit includes an air inlet, a pressure sensor 2, a pressure reducing valve 4, a proportional solenoid valve 7, and a solenoid valve 14. The pressure sensor 1 collects and feeds back the air pressure of the air circuit, and the pressure sensor 2 collects and feeds back the air pressure of the oxygen circuit. The mixing circuit includes an air bag 15, a proportional solenoid valve 17, and a flow sensor 18. The air bag 15 has a pressure sensor 16 for detecting and feeding back the pressure of the mixed gas in the air bag. After the mixed gas enters the body of the patient 22 from the inhalation port 20, the patient exhausts the gas in the patient's body through the exhala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com