Quantitative characterization method of shale reservoir pore system and method for evaluating pore characteristics of shale reservoir

A shale reservoir, quantitative characterization technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of difference in results, lack of quantitative statistical standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A quantitative characterization method of shale reservoir pore system, comprising:

[0041] (1) Determine the minimum magnification at which the electron microscope can observe organic pores.

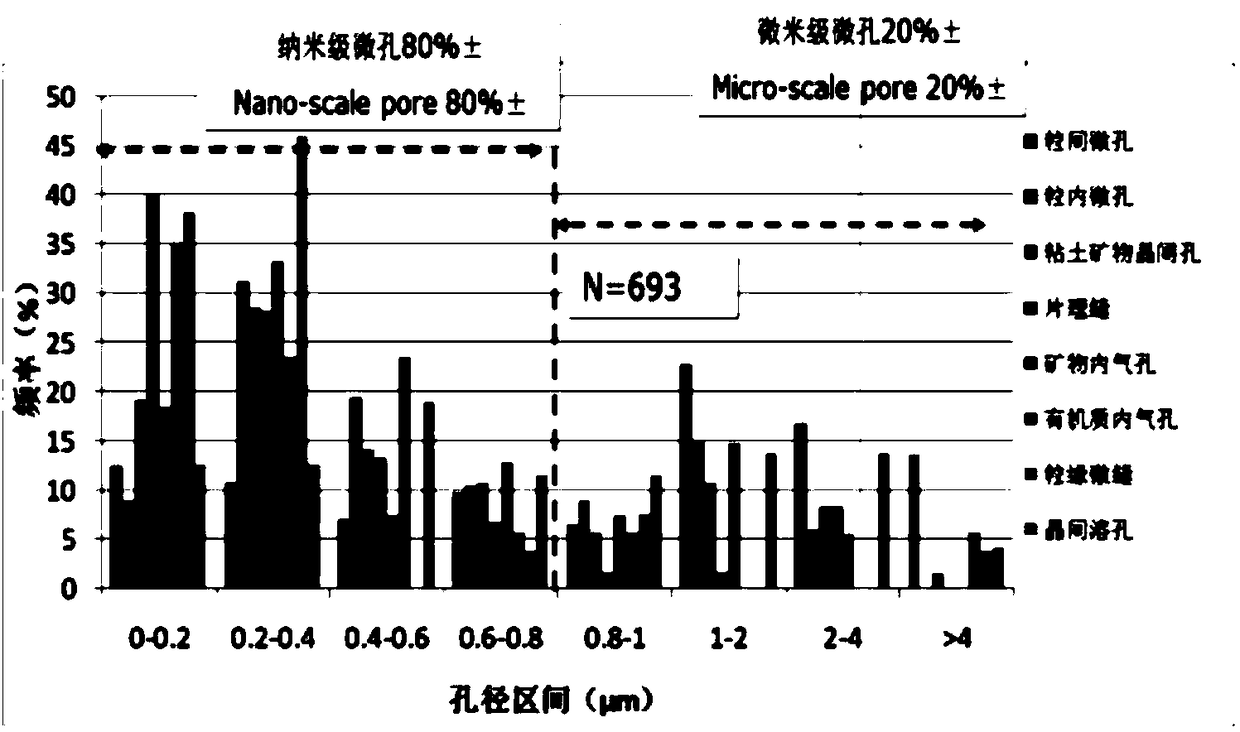

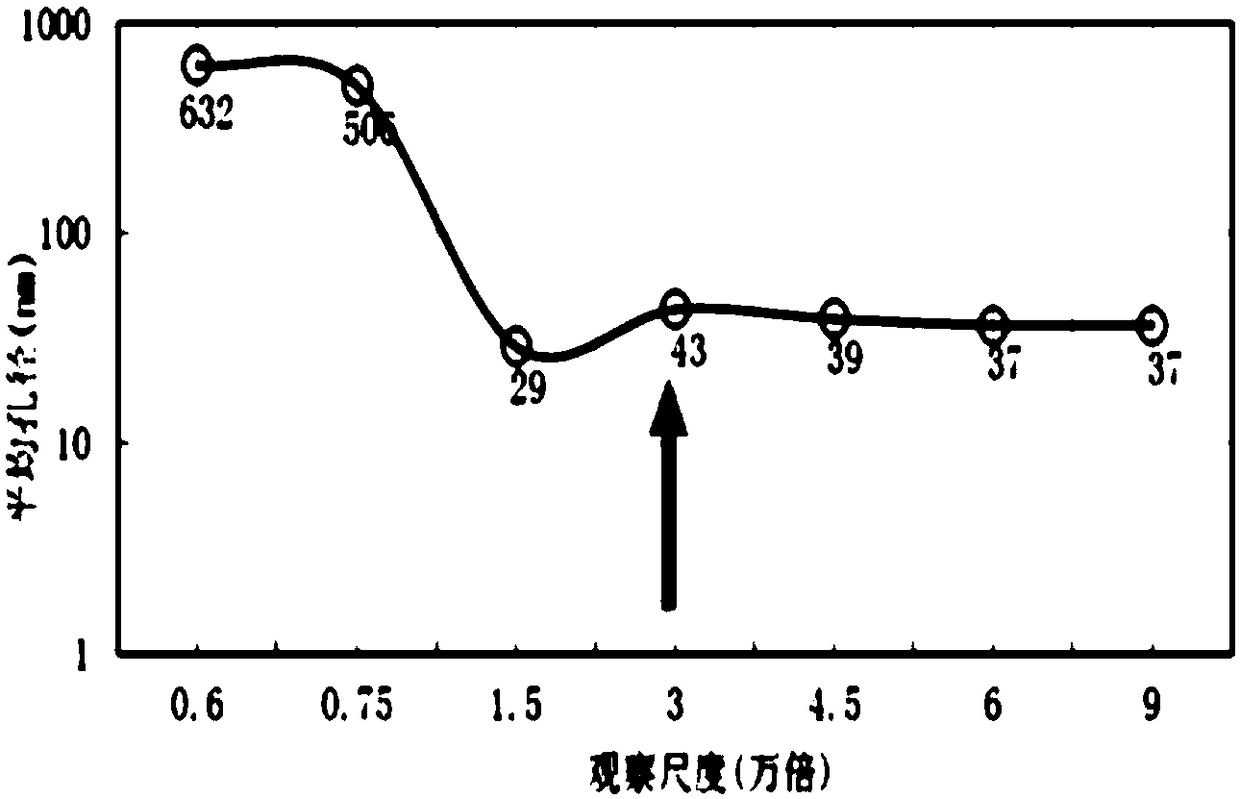

[0042] For the same sample, the electron microscope was used to observe the micro-nano pore characteristics of shale under different magnification conditions, and the pore diameter parameters were quantitatively counted, and the relationship between different magnifications and statistical micropore pore sizes was established. Such as figure 2 shown.

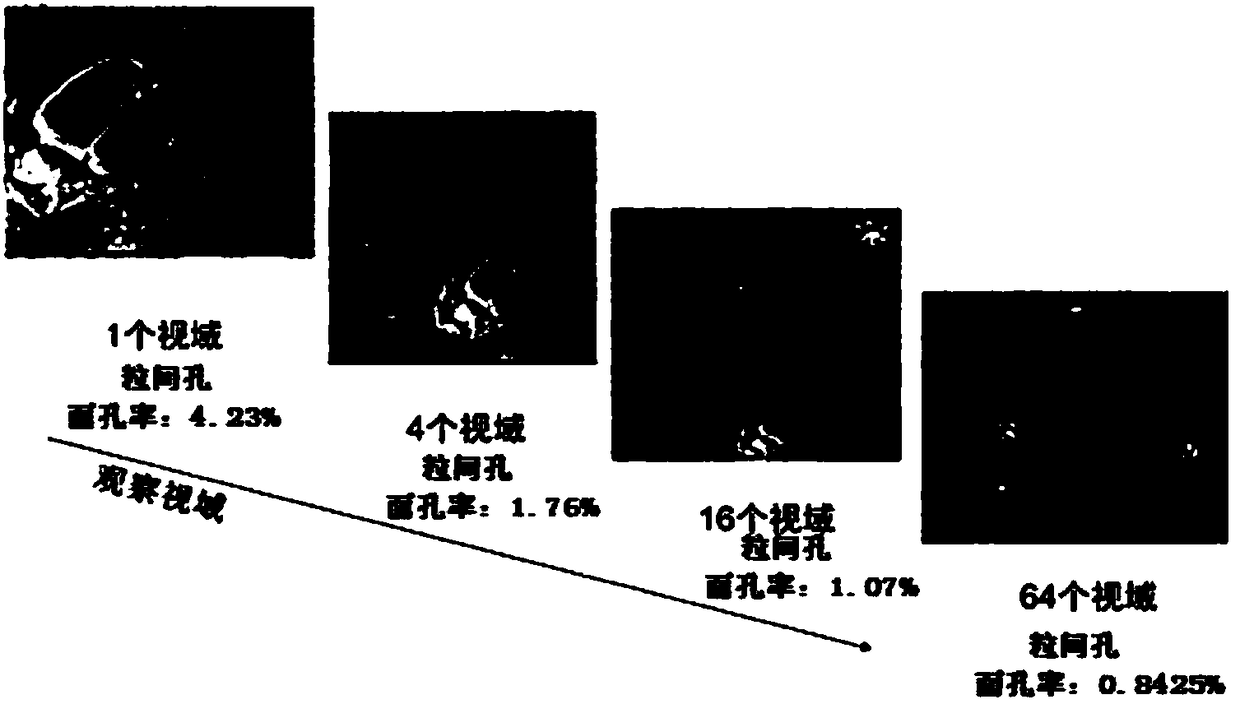

[0043] from figure 2 It can be shown in the results that: when the magnification is less than 30,000 times, the image statistics results are obtained after stitching 64 electron microscopic images, and the micropore parameters vary with the observed micropores. At low magnification, relatively large pores are mainly seen, and the statistical pore diameter is also large; as the magnification increases, the observed micropore di...

Embodiment 2

[0055] This example provides a quantitative characterization method for the pore system of shale reservoirs. The difference between this example and Example 1 is that the number of observation fields of the electron microscope image is different when the pore parameters are determined to be stable. This example Please refer to Example 1 for unmentioned parts.

[0056] A quantitative characterization method of shale reservoir pore system, comprising:

[0057] (1) Determine the minimum magnification at which the electron microscope can observe organic pores. Determine the minimum magnification to be greater than or equal to 30,000 times.

[0058] (2) Determine the minimum observation field number of the electron microscope image when the pore parameters tend to be stable. The determined minimum number of observation fields is 56.

[0059] (3) Use the software to quantitatively count and observe the pore parameters of the number of viewsheds.

[0060] The known software such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com