Intracavity coating roller brush

A roller brush and paint technology, which is applied in the direction of construction and building construction, can solve the problems of physical exertion, crushing efficiency, limited paint absorption, and easy environmental pollution of paint, so as to reduce paint dripping, improve painting efficiency, reduce The effect of the number of times of repeated dipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

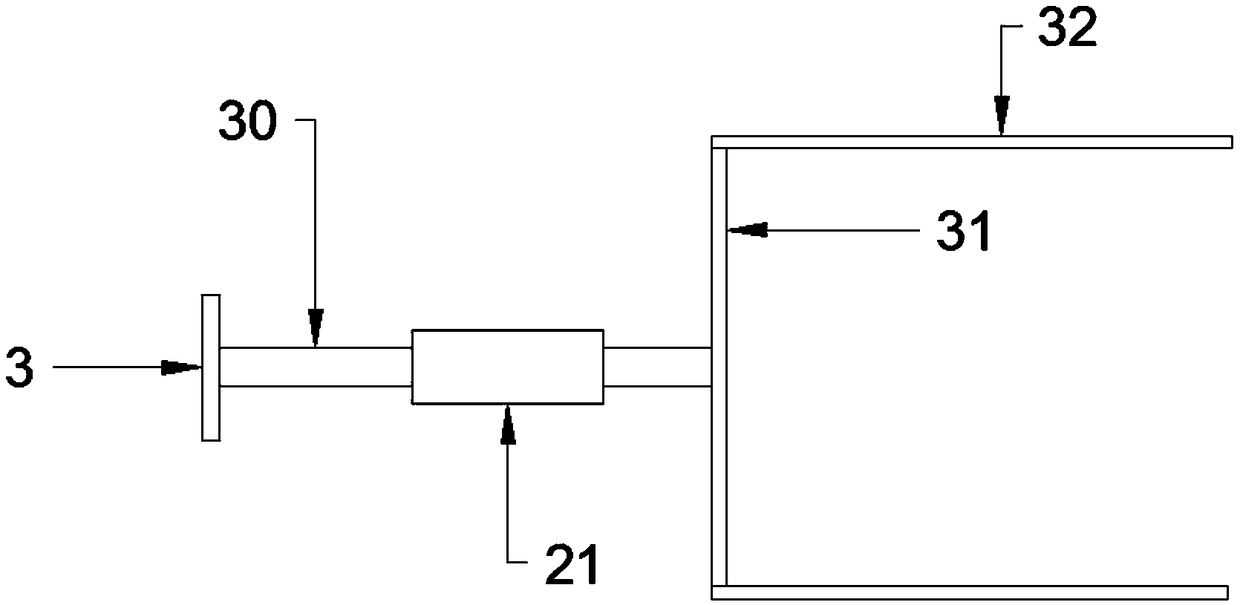

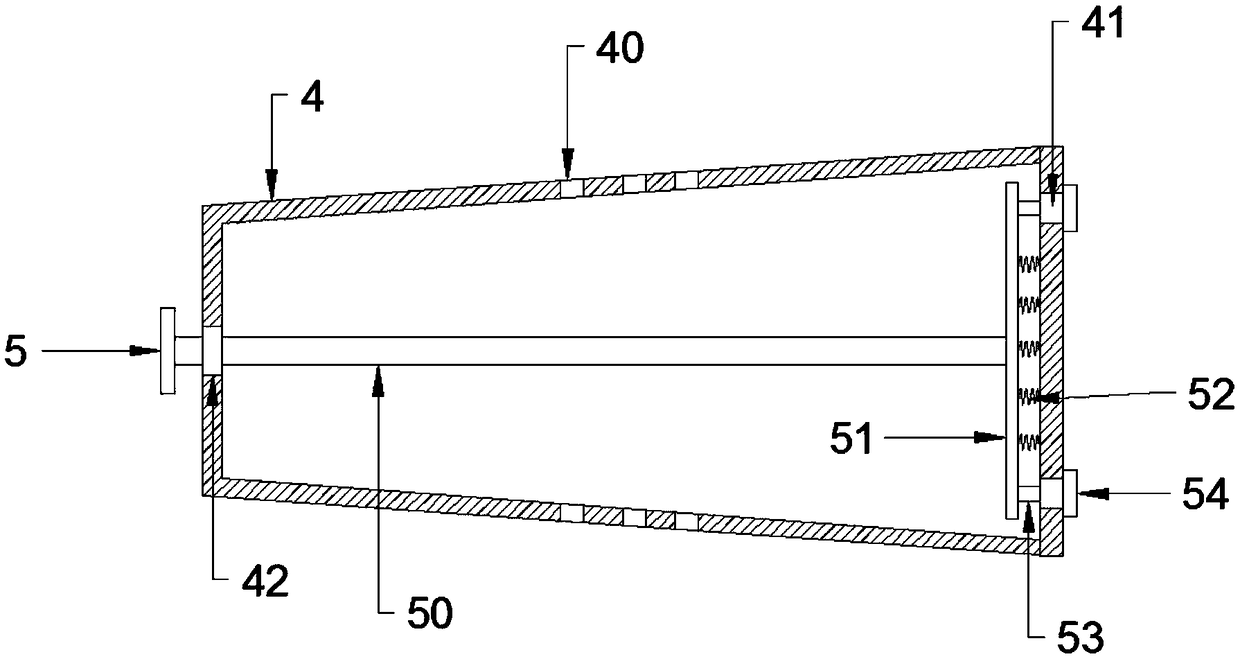

[0021] see Figures 1 to 4 , in the embodiment of the present invention, a kind of inner cavity type paint roller brush, comprises brush tube 1, brush layer 10, brush frame 2, painting handrail 6, and the front end of described painting handrail 6 is fixed U-shaped Brush holder 2, the bottom two sides of the brush holder 2 rotate and fix the brush holder 1, the surface of the brush holder 1 is fixed with a brush layer 10 for painting, and the outer wall of the brush holder 1 is provided with There are a plurality of overflow holes 11 communicating with the outer brush layer 10, the brush cylinder 1 is provided with a 4 for storing paint, and the right side of the paint cylinder 4 is provided with a feeding device, and the feeding device It is driven to open by the opening and closing device. The opening and closing device is installed on the left side wall of the brush tube 1. The surface of the paint tube 4 is provided with a plurality of leakage holes 40, and the paint tube ...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] The paint tube 4 is a horizontal frustum-shaped metal tube, the area of the left side wall of the paint tube 4 is smaller than the area of the right side wall of the paint tube 4, and the distance between the opening and closing cover plates 32 is larger than that of the left side of the paint tube 4. Diameter and less than the diameter of the circular platform on the right side of paint tube 4.

[0031] Working principle of the present invention: the setting of this circular platform can facilitate the opening and closing cover plate 32 to penetrate the side wall of the paint tube 4 from the left side and when it is close to the leakage hole 40, it will be stretched outwards, and the opening and closing cover plate 32 will be opened. The end can well cover the material leakage hole 40. When the paint cylinder 4 is filled with paint, the opening and closing cover plate 32 can block the material lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com