Comb type breakwater system capable of achieving wave power generation

A breakwater and wave energy technology, applied in breakwaters, ocean energy power generation, jetties, etc., can solve problems such as high construction costs, restrictions on the popularization and use of oscillating water column and oscillating buoy type power generation devices, and low energy harvesting efficiency, achieving enhanced continuous performance, reduce the risk of damage to the wing plate, and improve the effect of wave dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

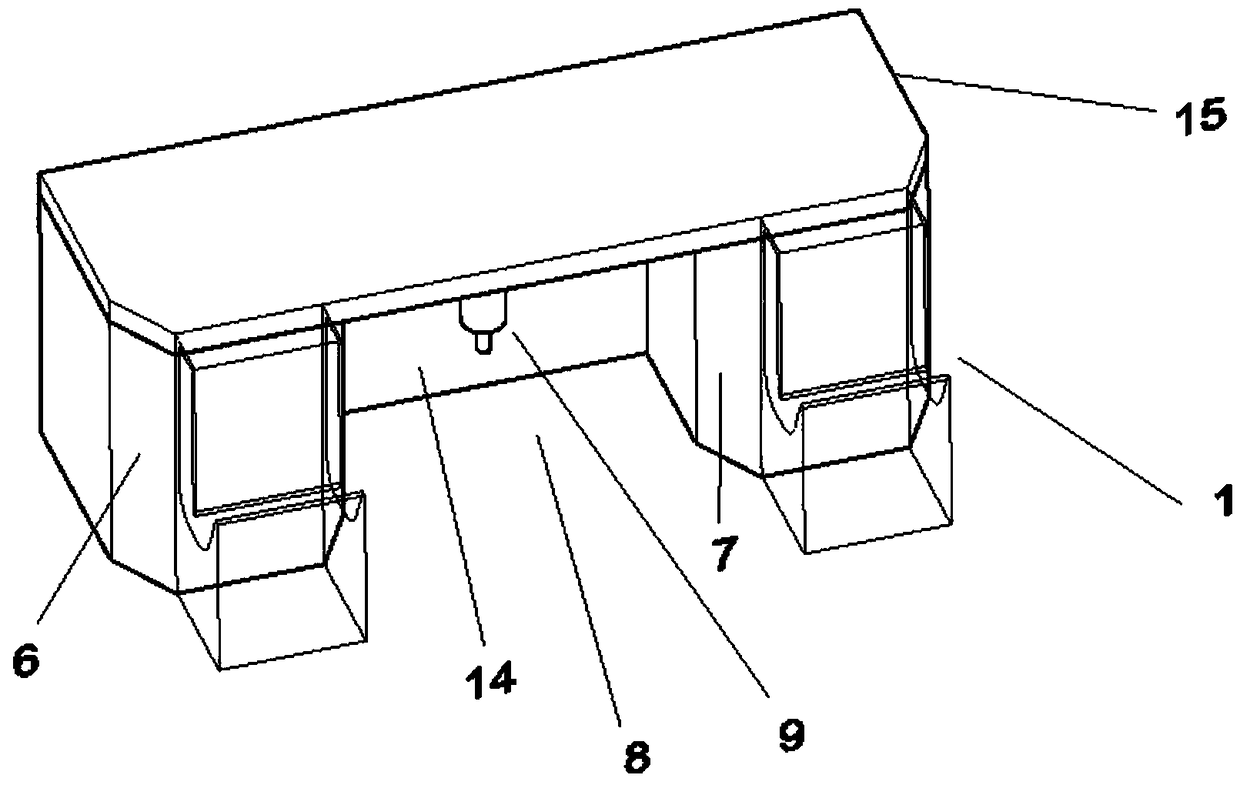

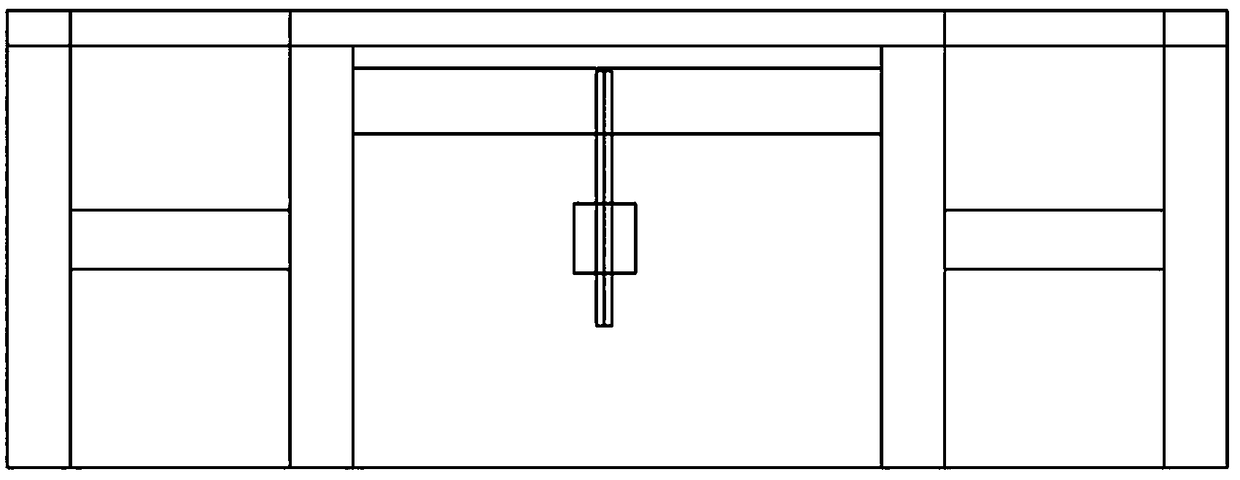

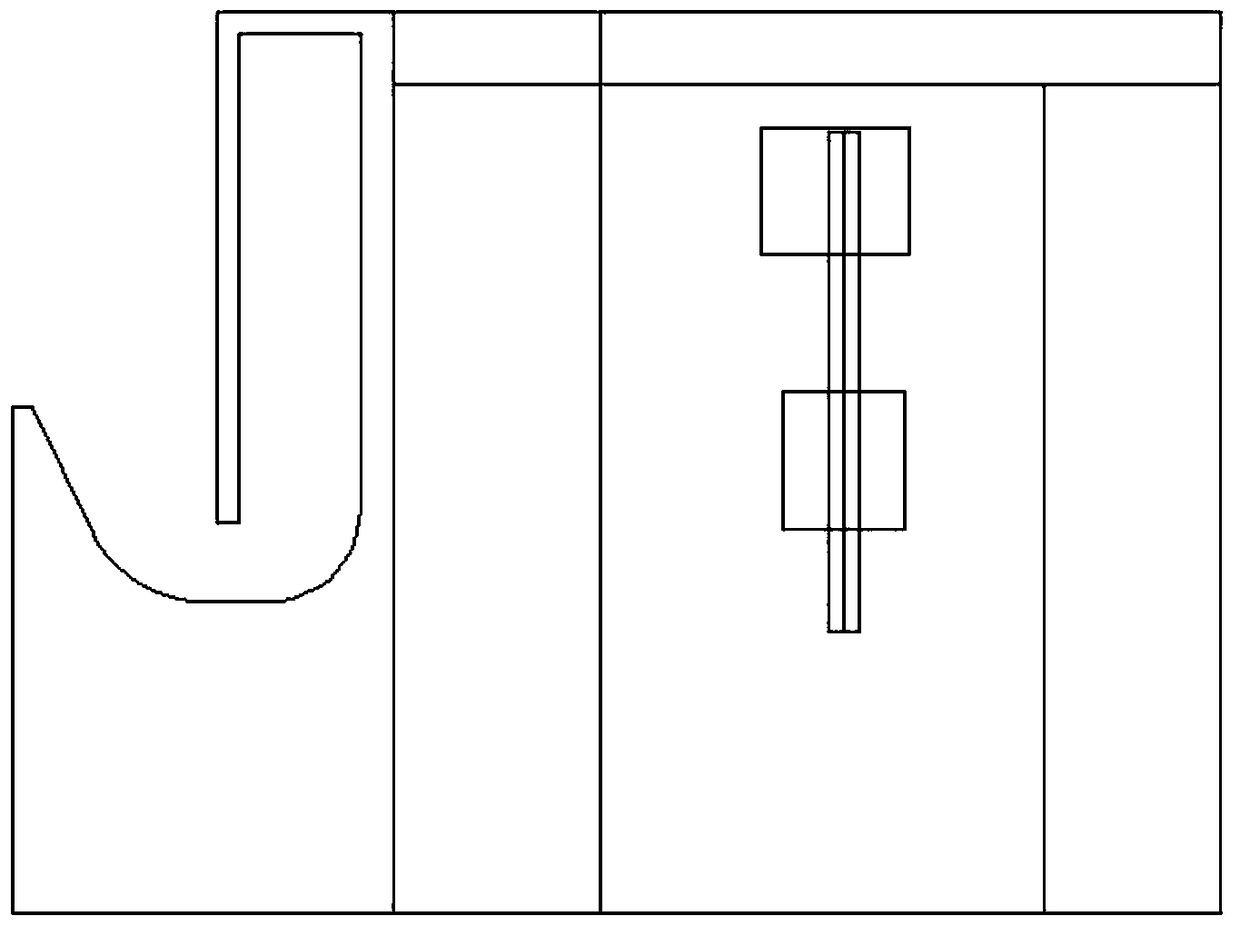

[0025] The PU-OWC&OB&CTBW system is placed on the riprap bed laid on the seabed, and consists of several units arranged continuously along the axial direction of the breakwater, such as figure 1 shown. The PU-OWC&OB&CTBW system consists of three parts: PU-OWC power generation device, oscillating buoy type power generation device and improved comb breakwater. The improved comb breakwater comprises a caisson 6, a diversion wall 7, a wing plate 14, and a breast wall 15, wherein the caissons 6 are arranged at intervals along the axial direction of the breakwater, and the wing plate 14 is arranged on the back wave side between adjacent caissons; the breast wall 15 It is installed above the caisson 6 and the wing plate 14; the PU-OWC power generation device 1 is placed on the wave-facing side of the caisson, and consists of a vertical upper wave breaker 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com