Tilted conveying belt loading and unloading mechanism with inspection function structure

A functional structure, inclined technology, applied in the field of inclined belt drive loading and unloading mechanism, can solve the problem of no detection platform, affecting the nearby detection efficiency, etc., to achieve the effect of improved functional structure and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

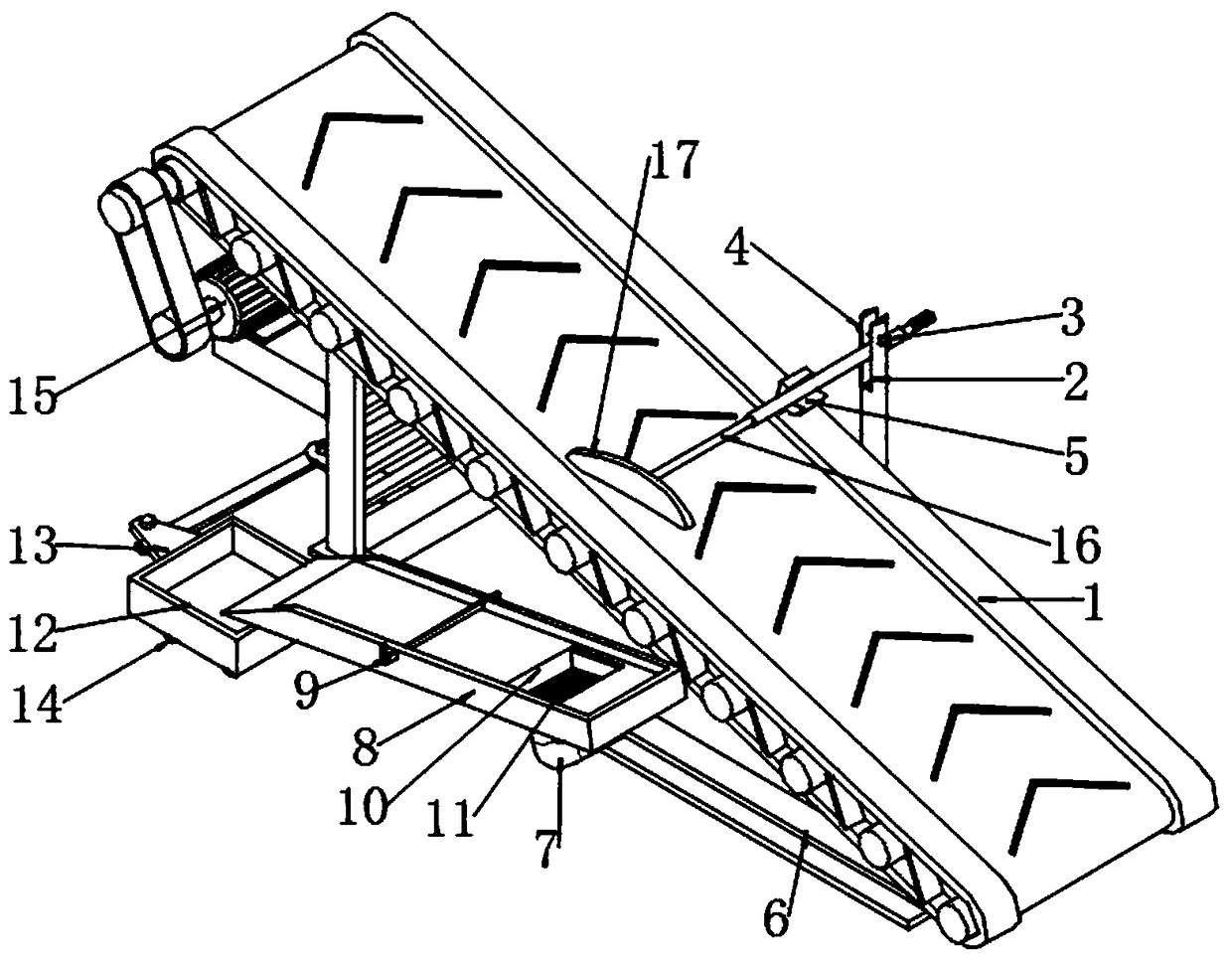

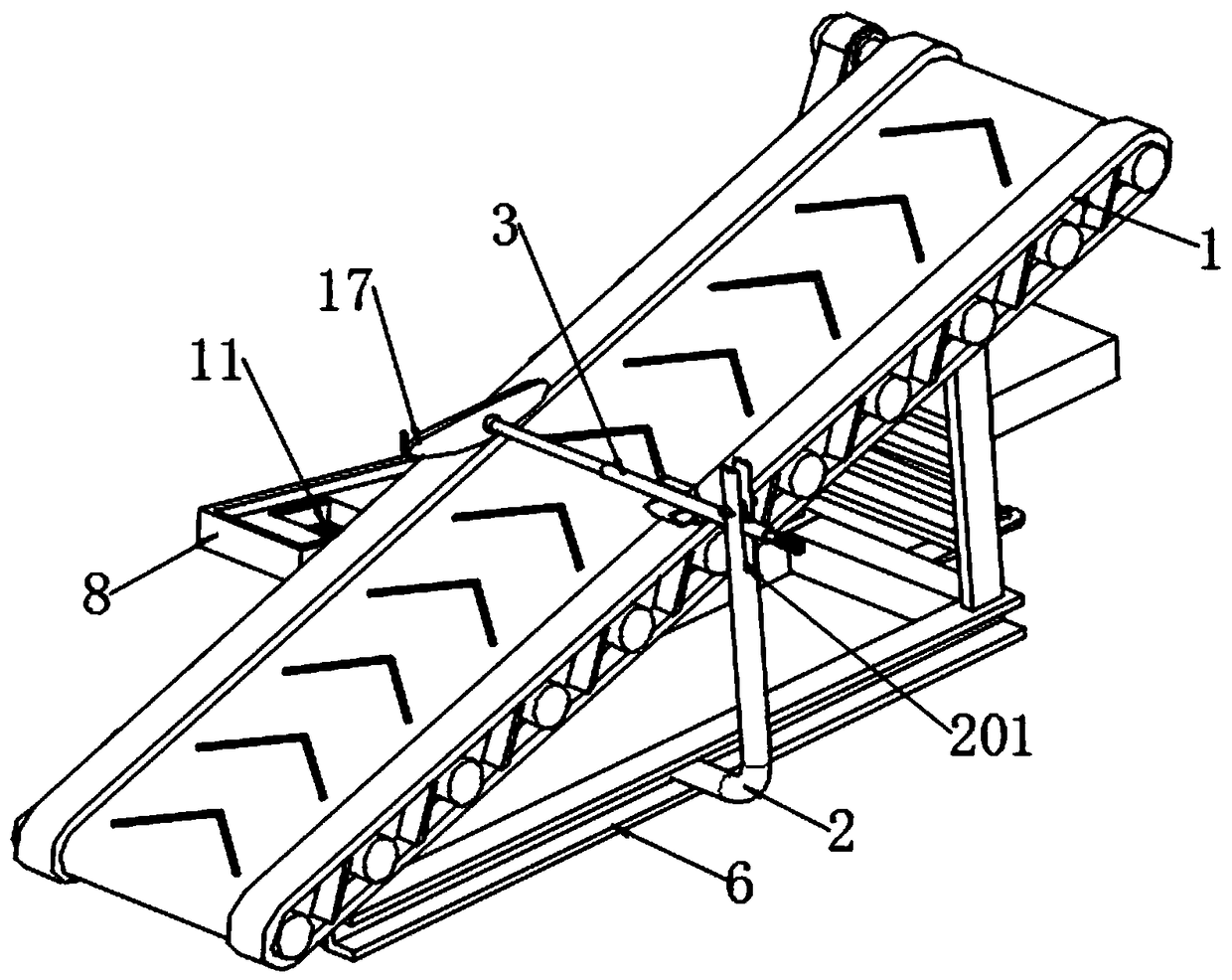

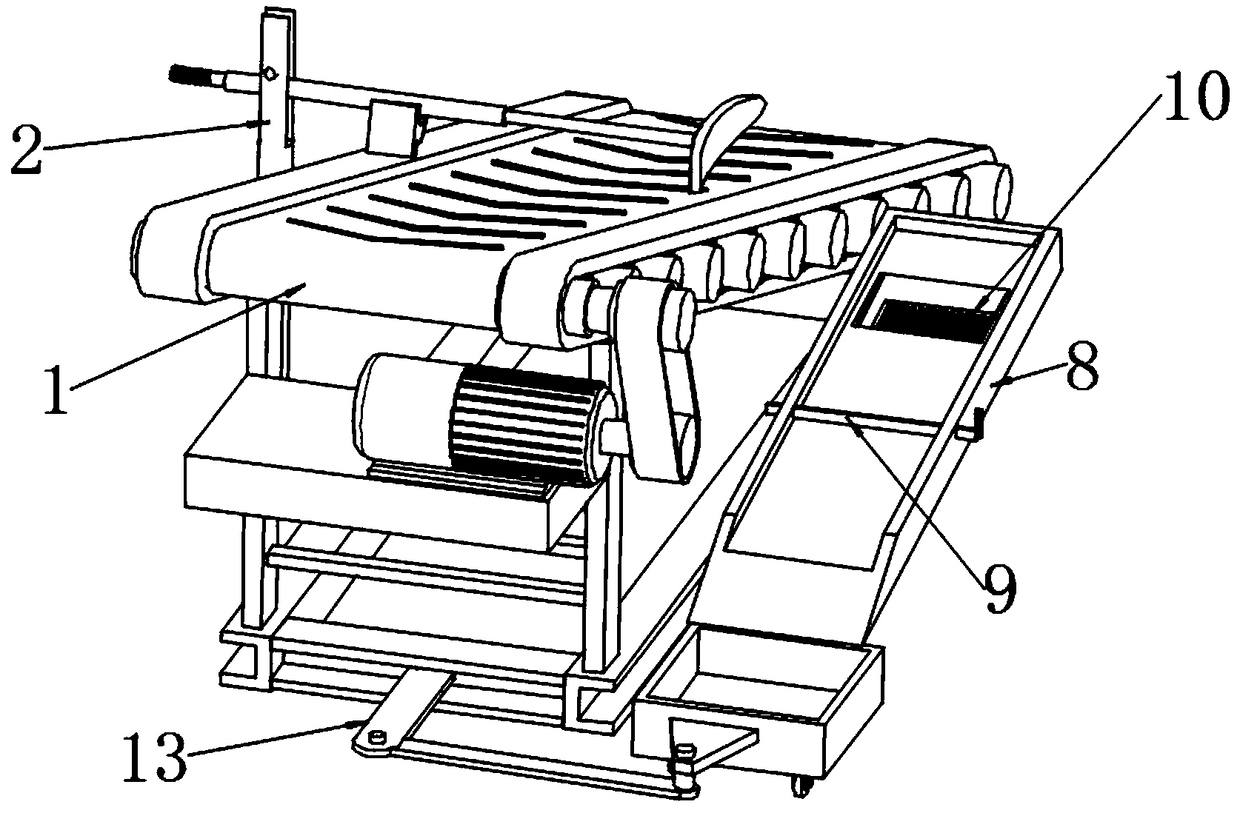

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034]The invention provides an inclined conveyor belt loading and unloading mechanism with inspection function structure, which includes a main body 1, a first support rod 2, a function hole 201, a function pipe 3, a lifting lug 301, a threading shaft 4, a guide seat 5, a bottom Frame 6, second support rod 7, functional seat 8, limit plate 9, functional slot 10, functional frame 11, trailer 12, connecting plate 13, universal moving wheel 14, motor 15, functional rod 16, reserved external thread 1601, the push plate 17 and the connecting shaft 18; the main body 1 is an inclined inclined-plane transmission mechanism composed of the motor 15, the roller assembly and the conveyor belt, and the bottom side of the main body 1 is respectively installed with a A first support rod 2 of a curved structure and a second support rod 7 of a curved structure; the top end of the first support rod 2 is provided with an open groove of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com