Clean workshop operation method based on sensor network, and clean workshop control system based on sensor network

A sensor network and workshop control technology, applied in the field of intelligent workshops, can solve the problems of imperfect technical design of working vehicles, untimely tracking and monitoring, etc., and achieve the effect of easy understanding and control, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

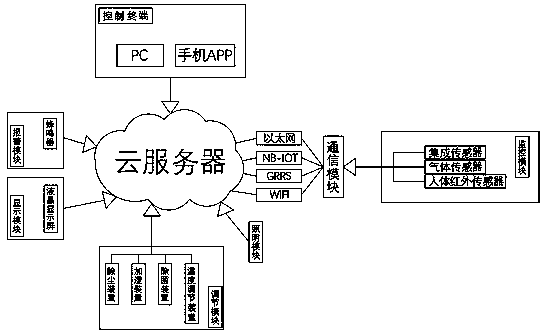

[0030] refer to Figures 1 to 4 , the system includes a control terminal, a cloud server, a monitoring module, an adjustment module, a lighting module, a display module, a communication module and an alarm module;

[0031] The monitoring module includes an integrated sensor, a gas sensor and a human body infrared sensor;

[0032] The regulating module includes a sterilizing device, a temperature regulating device, a humidifying device and a dust removing device;

[0033] The control terminal includes a PC and a mobile phone APP;

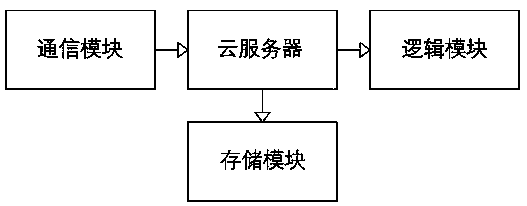

[0034] The cloud server is used to process the collected signals and realize the control function of the adjustment module, the monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com