Inspection device for containers

A container and flange technology, which is applied in the field of special inspection devices for containers, can solve problems such as prone to accidents, affect the quality of processed products, and reduce production efficiency, so as to avoid accidents, benefit product quality, and facilitate installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

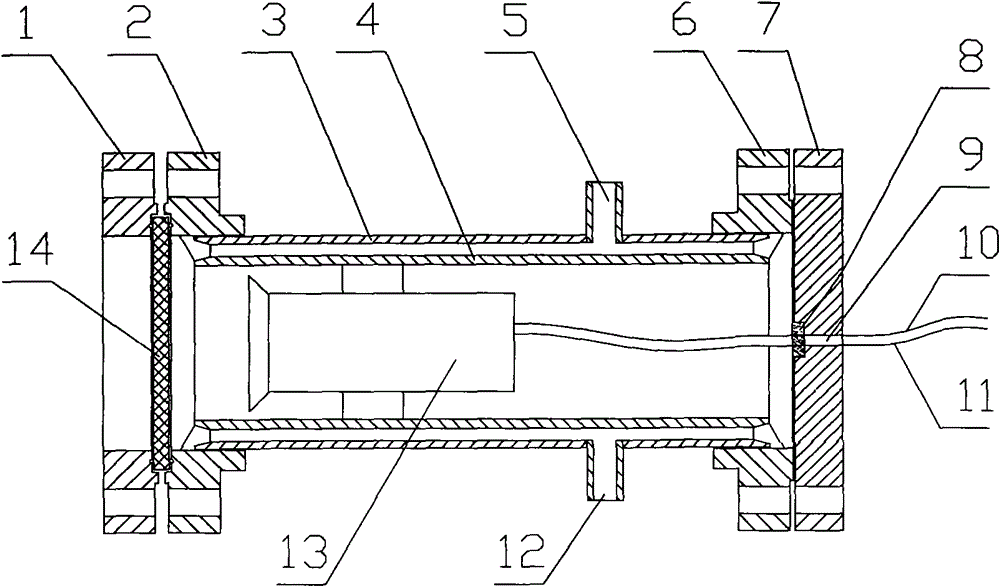

[0017] Such as figure 1 As shown, a special inspection device for containers is composed of a first flange 1, a second flange 2, a casing 3, a casing inner cavity 4, a water outlet 5, a third flange 6, a flange cover 7, and a power lead 10. It is composed of data wire 11, water inlet 12, camera 13, and glass lens 14.

[0018] Such as figure 1 As shown, a housing cavity 4 is provided in the housing 3, a first flange 1 and a second flange 2 are provided at the left end of the housing 3, and a flange 1 and a second flange 2 are arranged between the first flange 1 and the second flange 2. There are 14 glass lenses.

[0019] Such as figure 1 As shown, a water outlet 5 and a water inlet 12 are respectively provided on both sides of the casing 3, and the water outlet 5 and the water inlet 12 are respectively connected to an external water circulation cooling device.

[0020] Such as figure 1 As shown, a third flange 6 and a flange cover 7 are provided on the right end of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com