Inter-layer adhesive force testing component

A technology for interlayer adhesion and testing components, which can be used in measuring devices, instruments, and mechanical devices, etc., and can solve the problem that the tensile force cannot be guaranteed to be perpendicular to the surface of the sample to be tested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

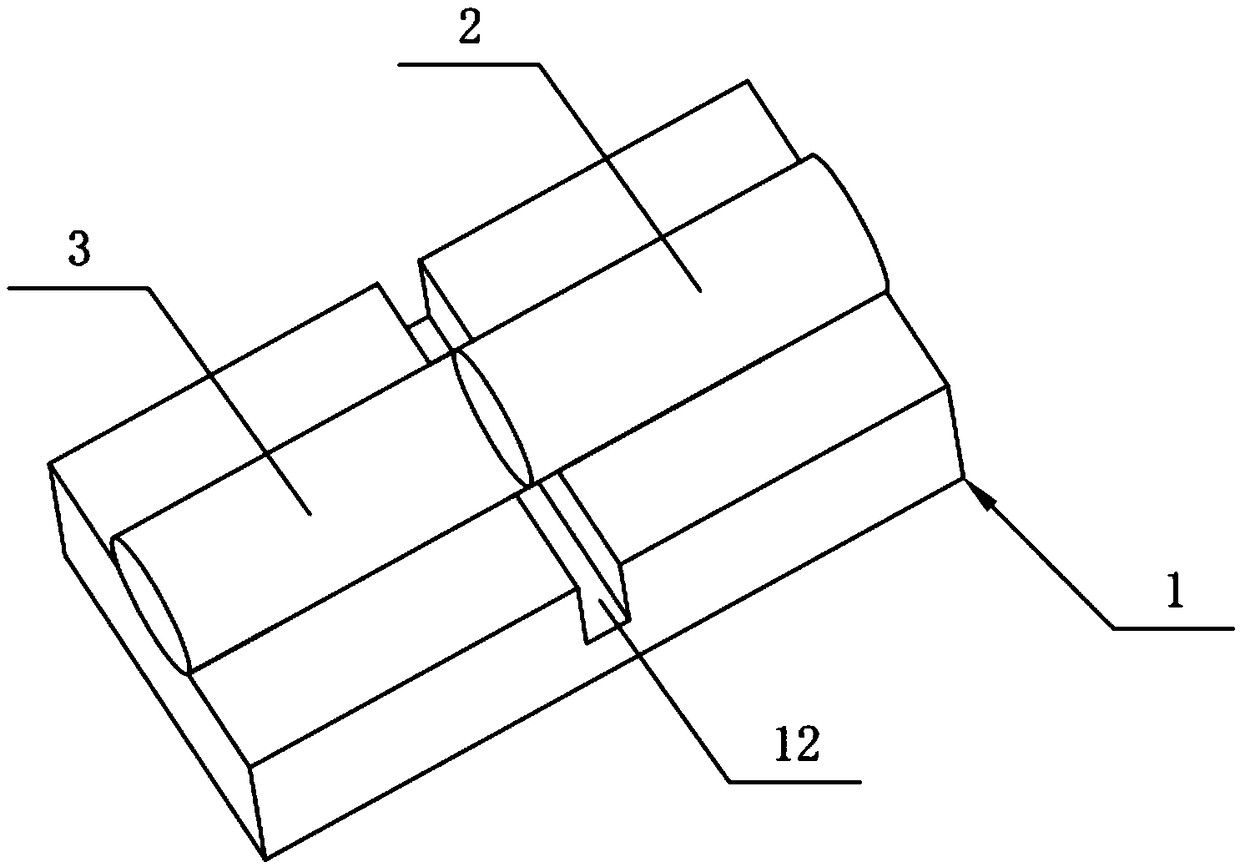

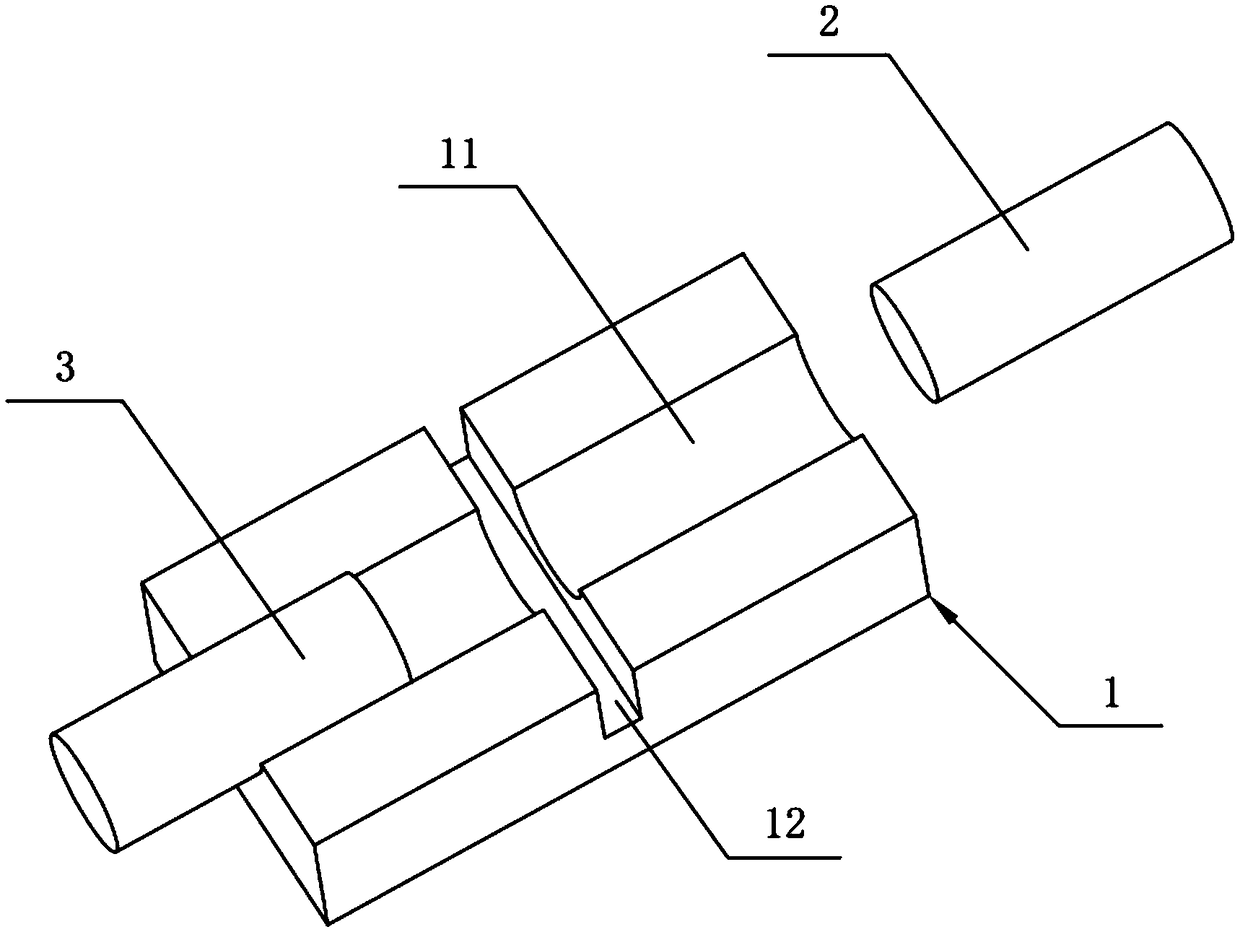

[0030] This embodiment provides a kind of interlayer adhesion testing assembly, such as figure 1 and figure 2 As shown, the interlayer adhesion test assembly includes a base 1, a first pulling column 2 and a second pulling column 3, wherein:

[0031] The above-mentioned base 1 may be in the shape of a rectangular block, and a sliding groove 11 is provided on the base 1 along the length direction, and the sliding groove 11 is used for placing the first pulling column 2 and the second pulling column 3 . Specifically, the cross-sectional shape of the chute 11 is adapted to the cross-sectional shape of the first drawing column 2 and the second drawing column 3. For example, in this embodiment, the cross-sectional shape of the chute 11 can be a semicircle, while the first The cross-sectional shape of the drawing column 2 and the second drawing column 3 is circular. The cross-sectional shape of the chute 11 may also be rectangular, and the cross-sectional shapes of the first pull...

Embodiment 2

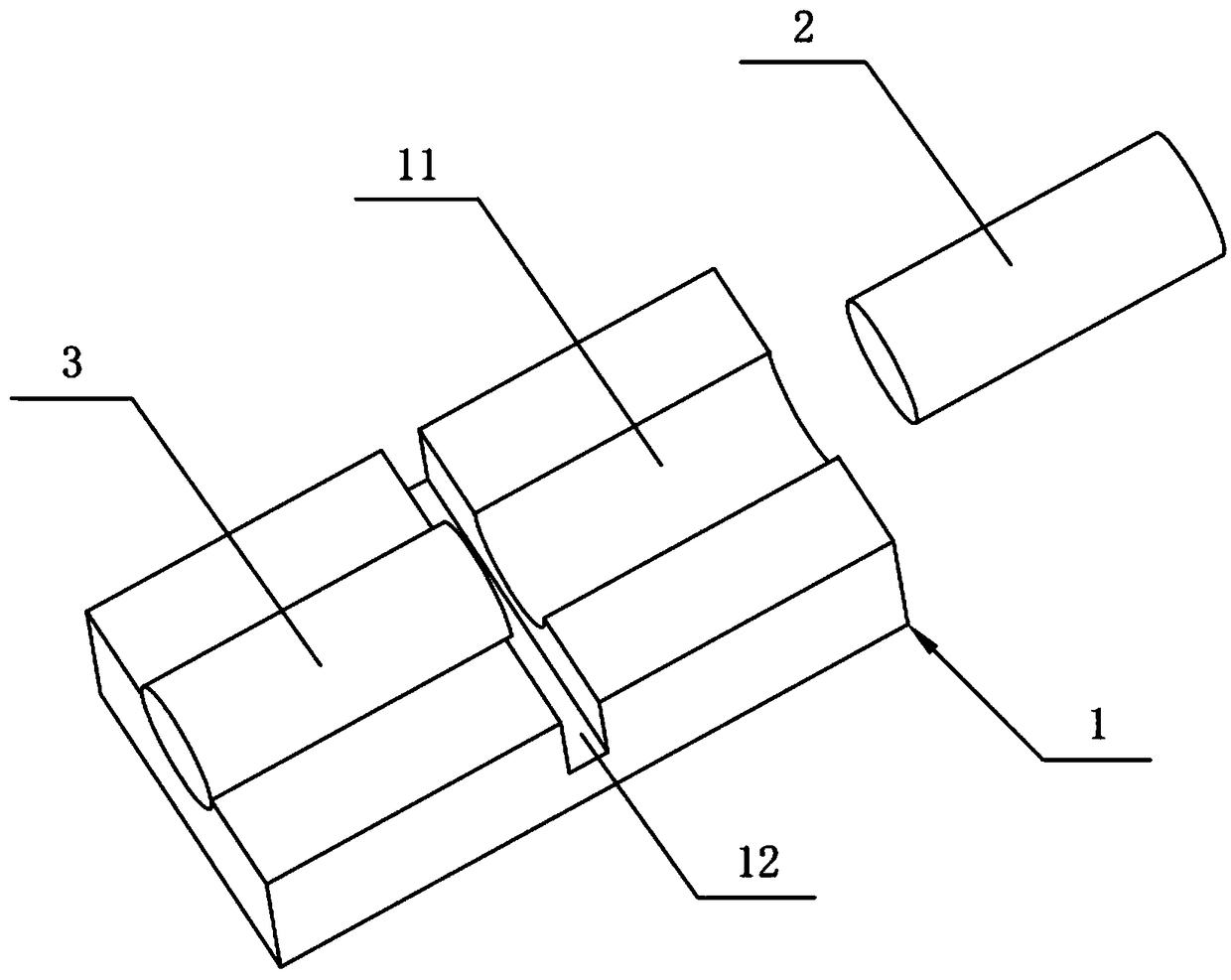

[0041] The difference between the present embodiment and the first embodiment lies in that the second pulling column 3 of the interlayer adhesion testing assembly of the present embodiment is fixed on the base 1 , and the second pulling column 3 is not connected with a tensile force detection element. Specifically, refer to image 3 , the second pulling column 3 of the interlayer adhesion test assembly of this embodiment is fixedly arranged at the chute 11 , and only the first pulling column 2 is connected with a tension detection piece. The rest of the structure of the interlayer adhesion testing component of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0042]When the above-mentioned interlayer adhesion test assembly of the present embodiment is in use, first the first pulling column 2 is placed on the chute 11, and then one of the film layers or the base layer of the sample to be tested is adhered to the first pulling column 2. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com