Device for simulating shearing friction of pipe joint of jacking pipe and rocky surrounding rock and testing method

A pipe joint and rock technology, applied in the field of pipe jacking construction, can solve problems such as sharp increase in friction and pipe jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

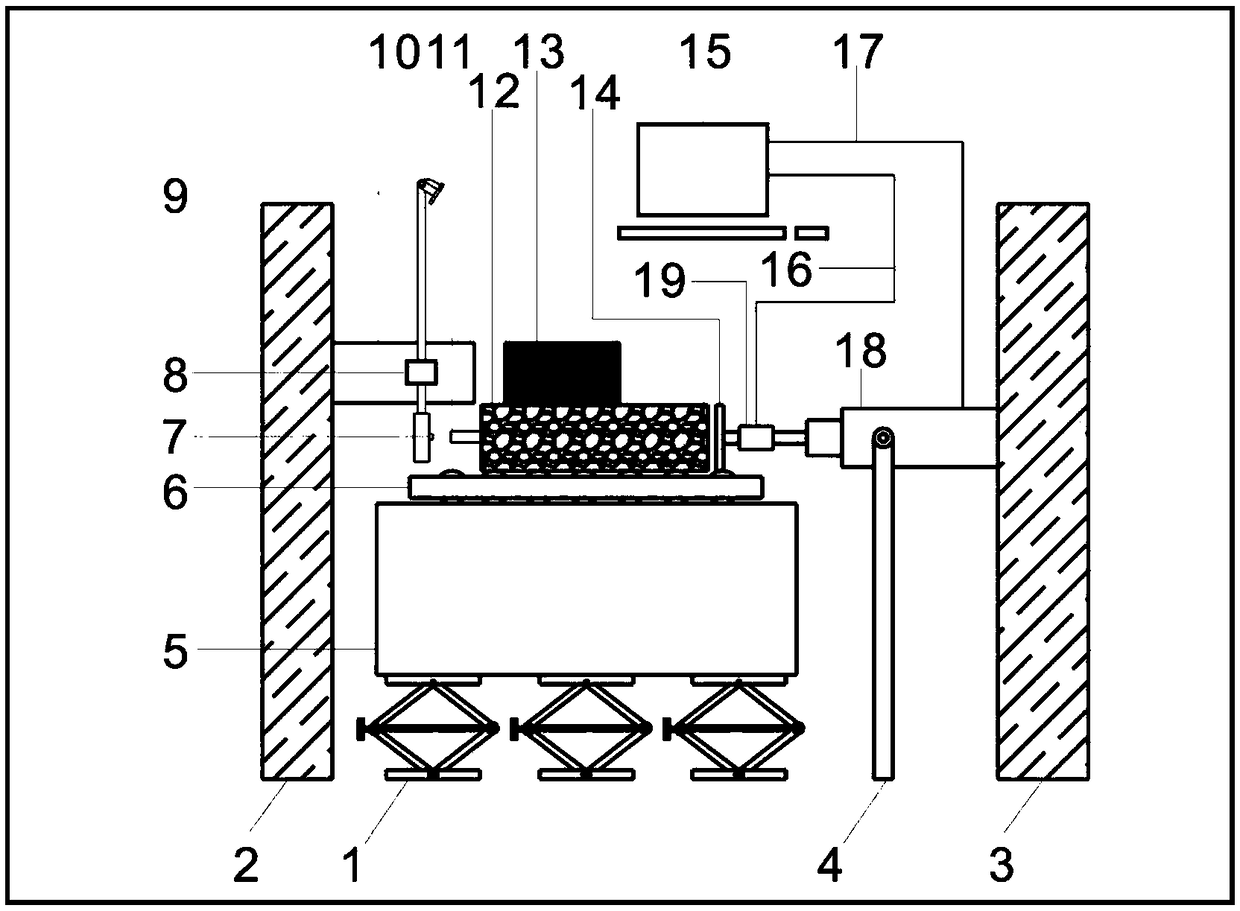

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] The reference signs in the accompanying drawings of the specification include:

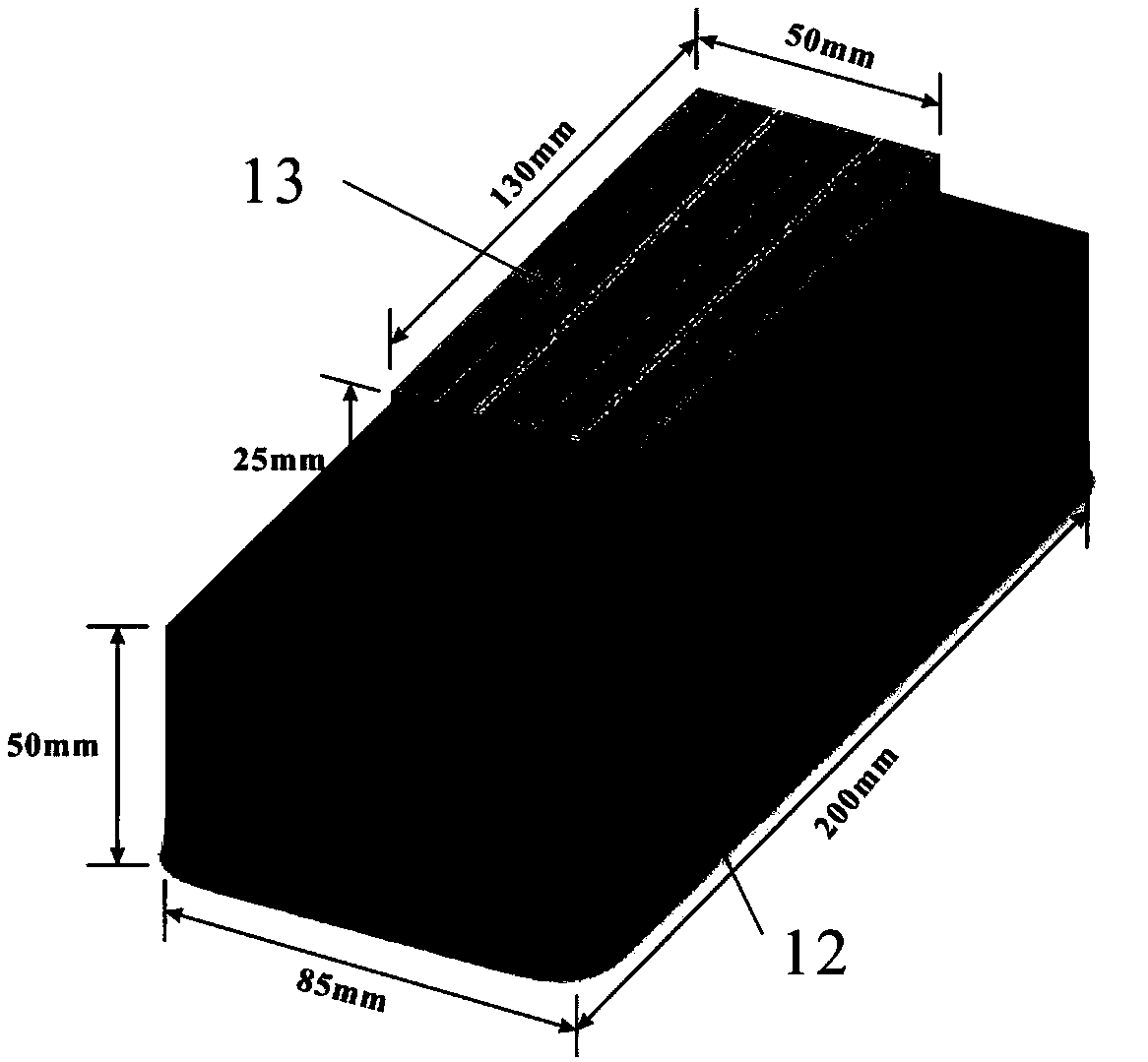

[0026] Diamond jack 1, first reaction wall 2, second reaction wall 3, support rod 4, rigid block 5, ball base 6, selfie stick button 7, selfie stick 8, mobile phone 9, fixed pole 10, trigger terminal 11 , rock base 12, concrete test piece 13, push plate 14, computer 15, first wire 16, second wire 17, hydraulic jack 18, pressure sensor 19.

[0027] Such as figure 1 A device for simulating the shear friction between the pipe jacking pipe joint and the rock surrounding rock is shown, including a cuboid rigid block 5 and a lifting mechanism installed at the bottom of the rigid block 5. The lifting mechanisms are three groups evenly arranged on the rigid block 5 The rhombus jack 1 at the bottom can realize the lifting of the rigid block 5 pads by the rhombu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com