Homogenizing-sheet control platform for follow spotlights

A technology for controlling a platform and a homogenizer, applied in the field of follow-spot lights, can solve the problems of complex focusing process, troublesome adjustment of the homogenizer, and inability to adjust accurately, so as to achieve safe and convenient use, good stage effects, and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

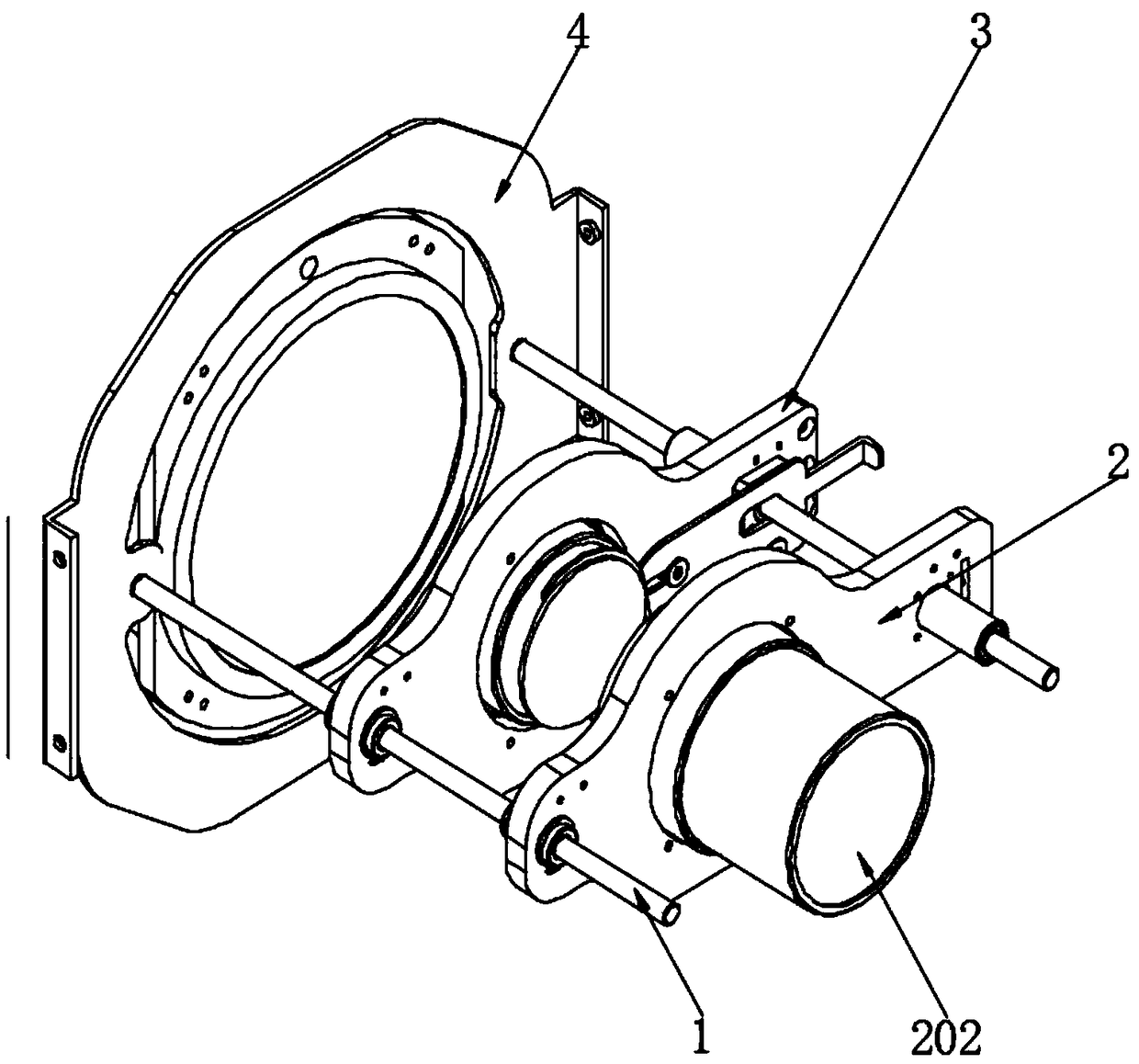

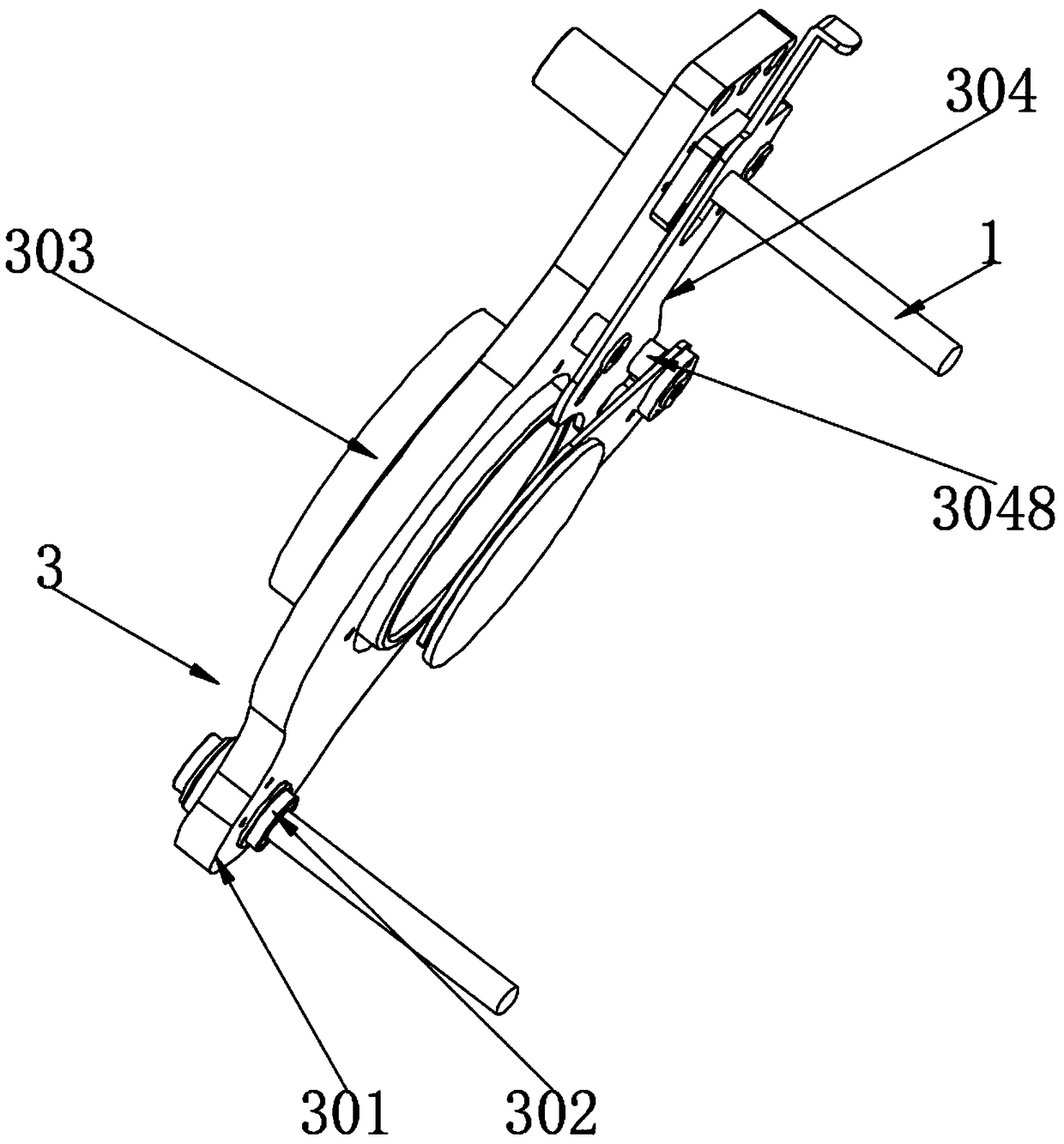

[0026] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a homogenizing film control platform for follow spot lights, including an adjustment slide bar 1, a focusing lens assembly 2 is installed at one end of the adjustment slide bar 1, and the middle part of the adjustment slide bar 1 is installed There is a magnifying glass assembly 3, and an objective lens assembly 4 is installed at the other end of the adjustment slide bar 1.

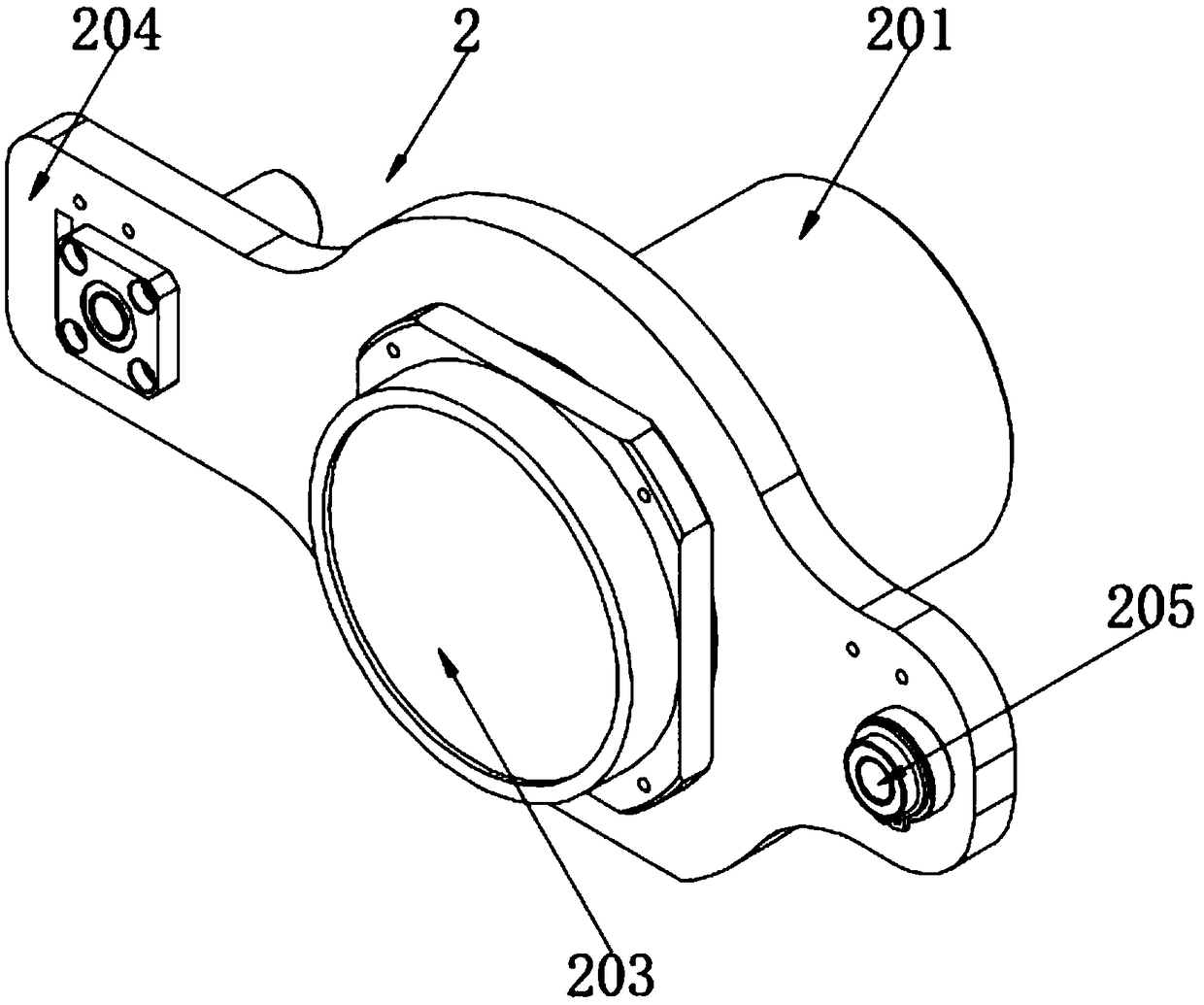

[0027] The focusing lens assembly 2 includes a fixed tube 201, a light inlet lens 202, a focusing lens 203, a first fixing frame 204 and a first fixing sliding hole 205, and first fixing sliding holes 205 are provided at both ends of the first fixing frame 204, The middle part of the first fixing bracket 204 is interspersed with a fixed tube 201, one end of the fixed tube 201 is embedded with a light-incoming lens 202, and the other end of the fixed tube 201 is embedded with a focusing lens 203, in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com