Small automatic wall building machine

A wall-laying machine and automatic technology, which is applied in construction, building structure, and processing of building materials, etc., can solve problems such as low labor efficiency, consumption of manpower, material and financial resources, and increased risk factor of workers, so as to improve work efficiency, The effect of improving project quality and reducing labor level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

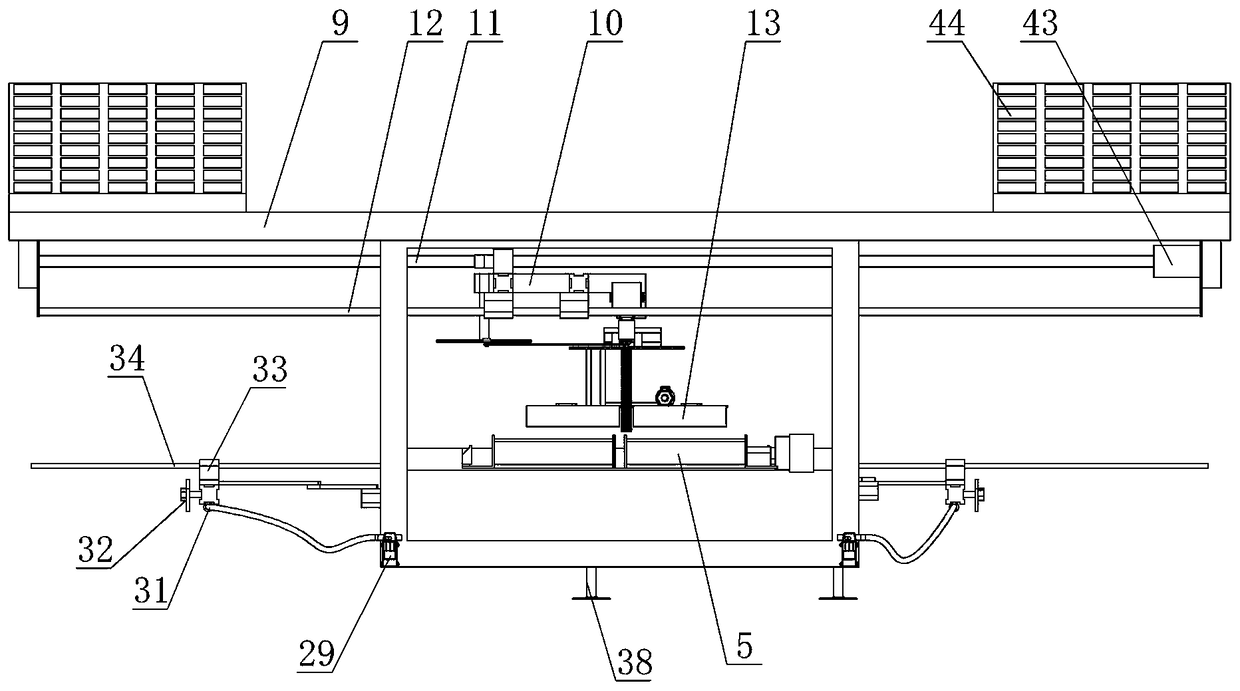

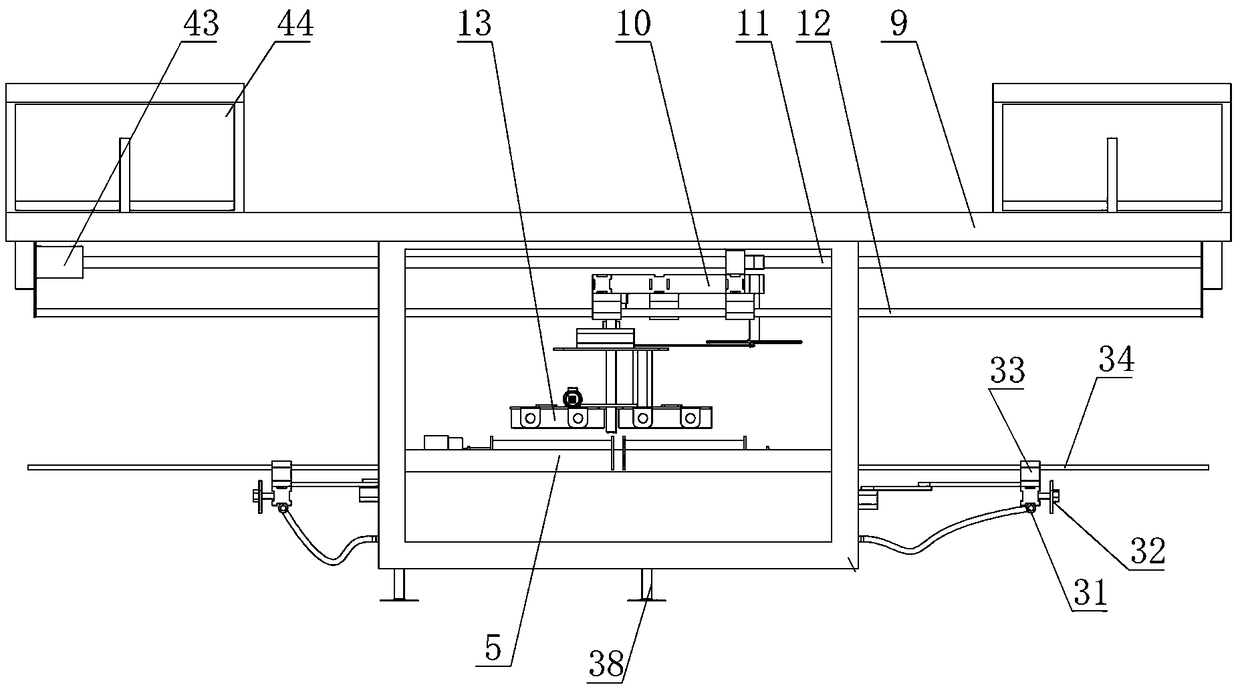

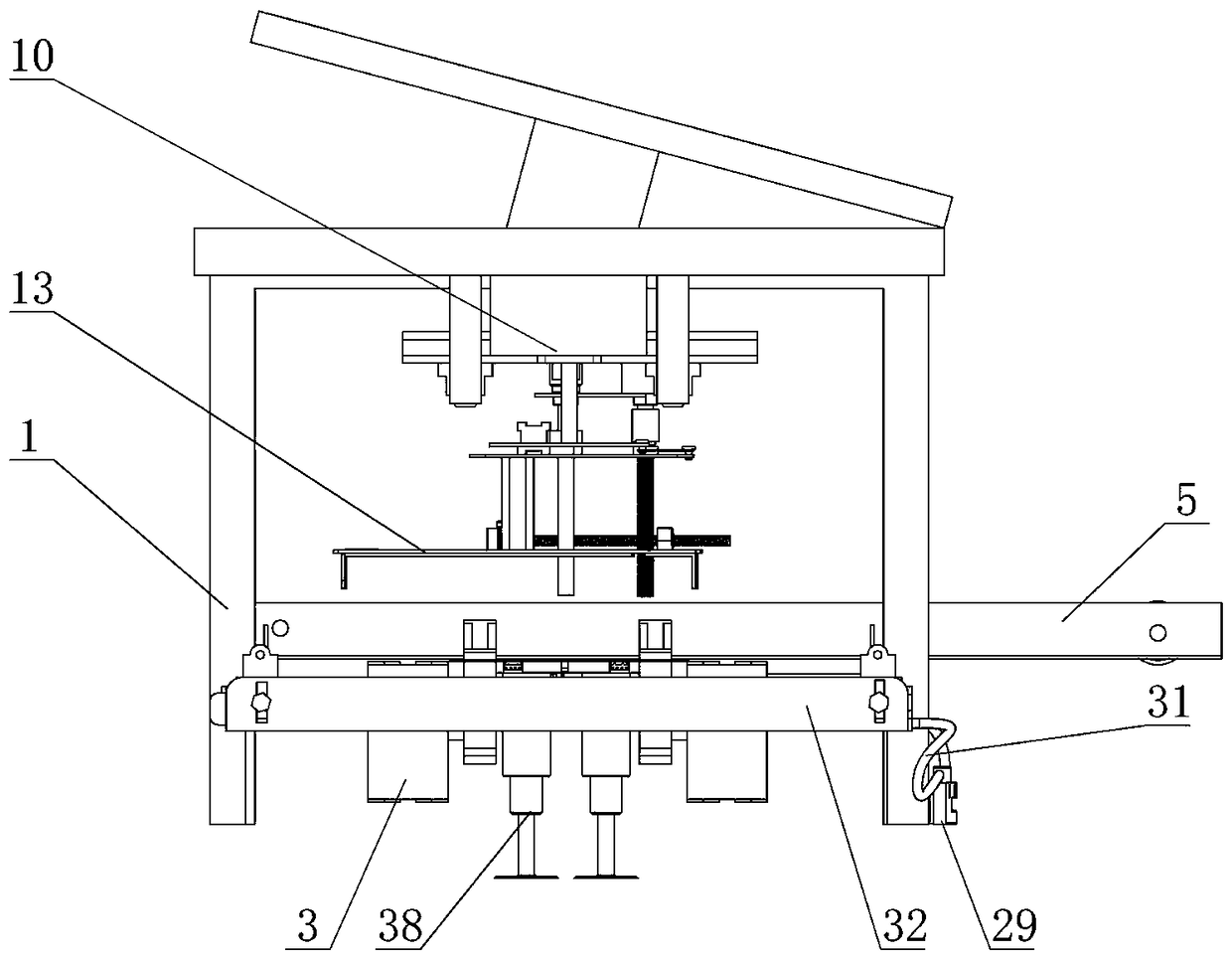

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as Figure 1 to Figure 5 As shown, the front view, rear view, left view, right view and bottom view of the small automatic wall-laying machine of the present invention are provided respectively, Image 6 , Figure 7 Both provide the perspective view of the small automatic wall-building machine of the present invention, the shown small-scale automatic wall-building machine is made up of frame 1, walking mechanism, transmission mechanism, clamping mechanism, moving mechanism, injection mechanism, lifting mechanism, machine The frame 1 plays a role of fixing and supporting, the upper end of the frame 1 is provided with a top plate 9, and the lower end forms a gap matched with the brick wall, and the traveling mechanism is arranged in the lower end gap of the frame 1. The walking mechanism shown is composed of a traveling motor 2, two crawler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com