Turnover bag moving and locating structure and method

A technology of mobile positioning and positioning method, applied in garbage collection, household appliances, applications, etc., can solve the problems of sanitation, hidden dangers, high labor costs, cumbersome operations, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

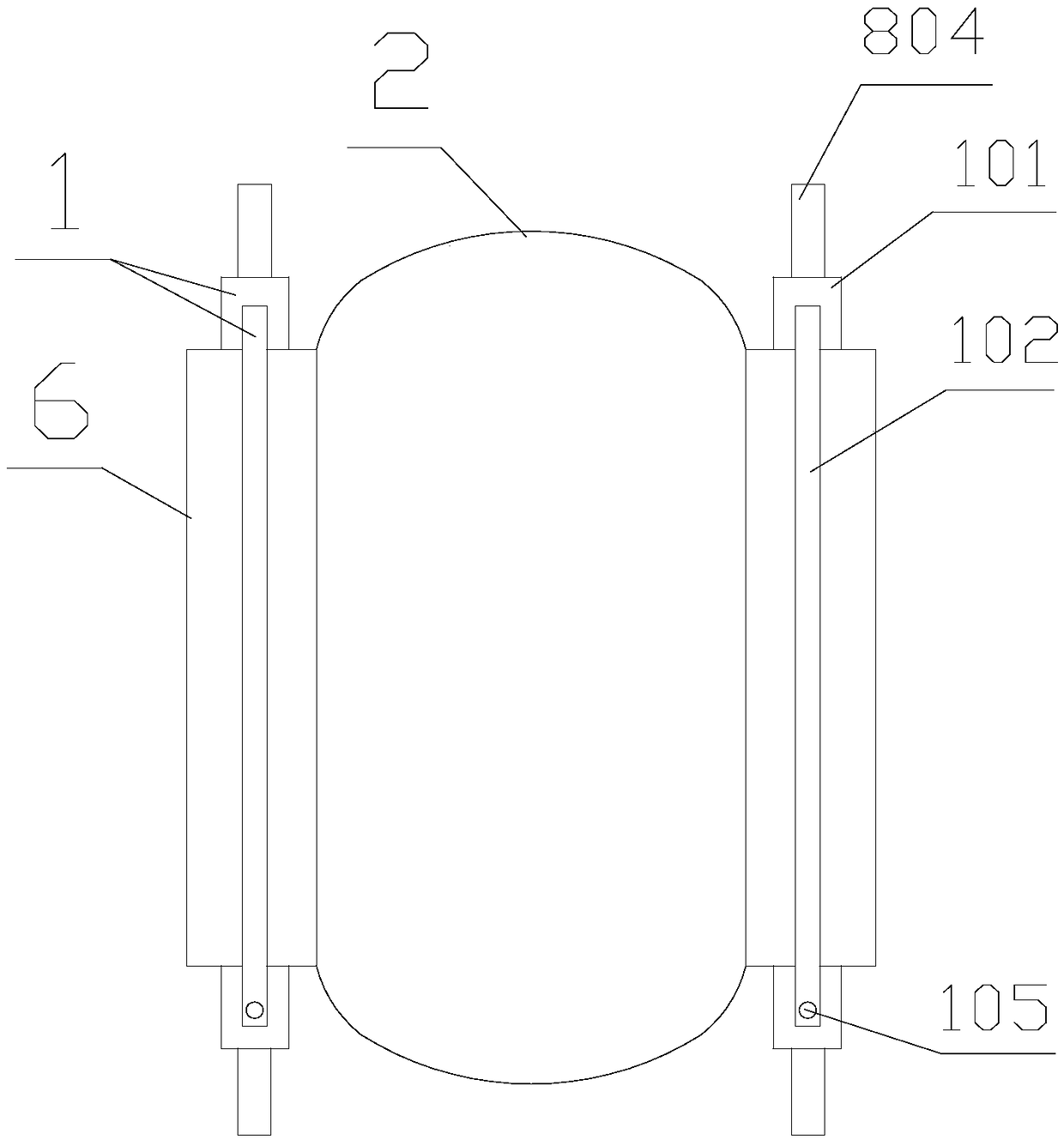

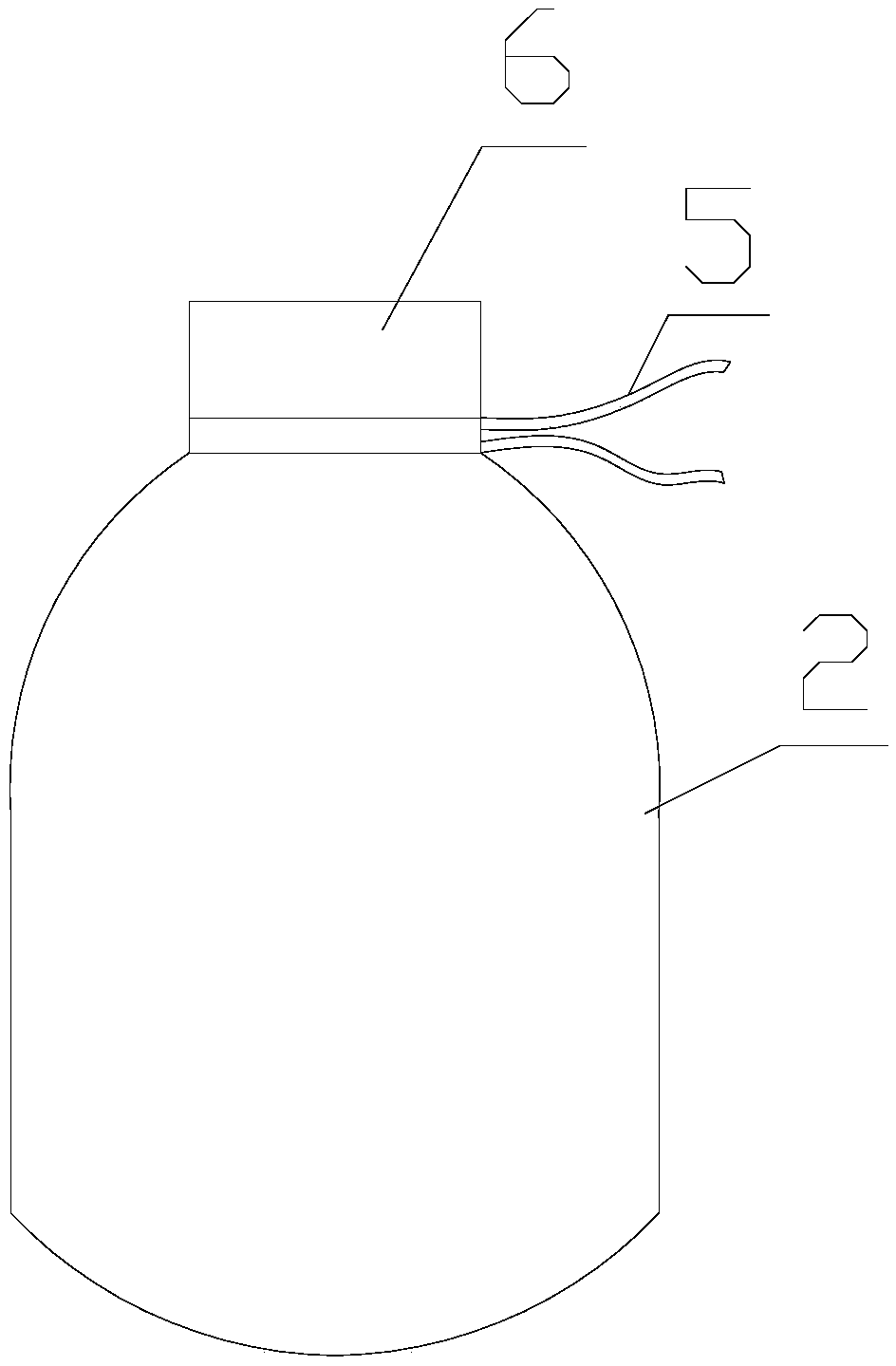

[0044] The invention provides a mobile positioning structure for a turnover bag, which includes a positioning splint 1, a guide mechanism 8 and a control terminal; There are several virtual positions 4, the positioning splint 1 is erected at the mouth of the corresponding virtual position 4 on the storage bin 3, the turnover bag 2 is accommodated in the virtual position 4, the axis direction of the positioning splint 1 is perpendicular to the axis direction of the storage bin 3, The axial length of positioning splint 1 is greater than the radial length of storage bin 3; Described guiding mechanism 8 comprises linear guide rail 801 and slide block 802, and linear guide rail 801 is located at the warehouse mouth place of storage bin 3, and the axial direction and storage bin 3 The axial directions of the two slides are parallel, and the slide block 802 slides along the linear guide rail 801; two slide blocks 802 are symmetrically arranged on both sides of the mouth of each virtua...

Embodiment 2

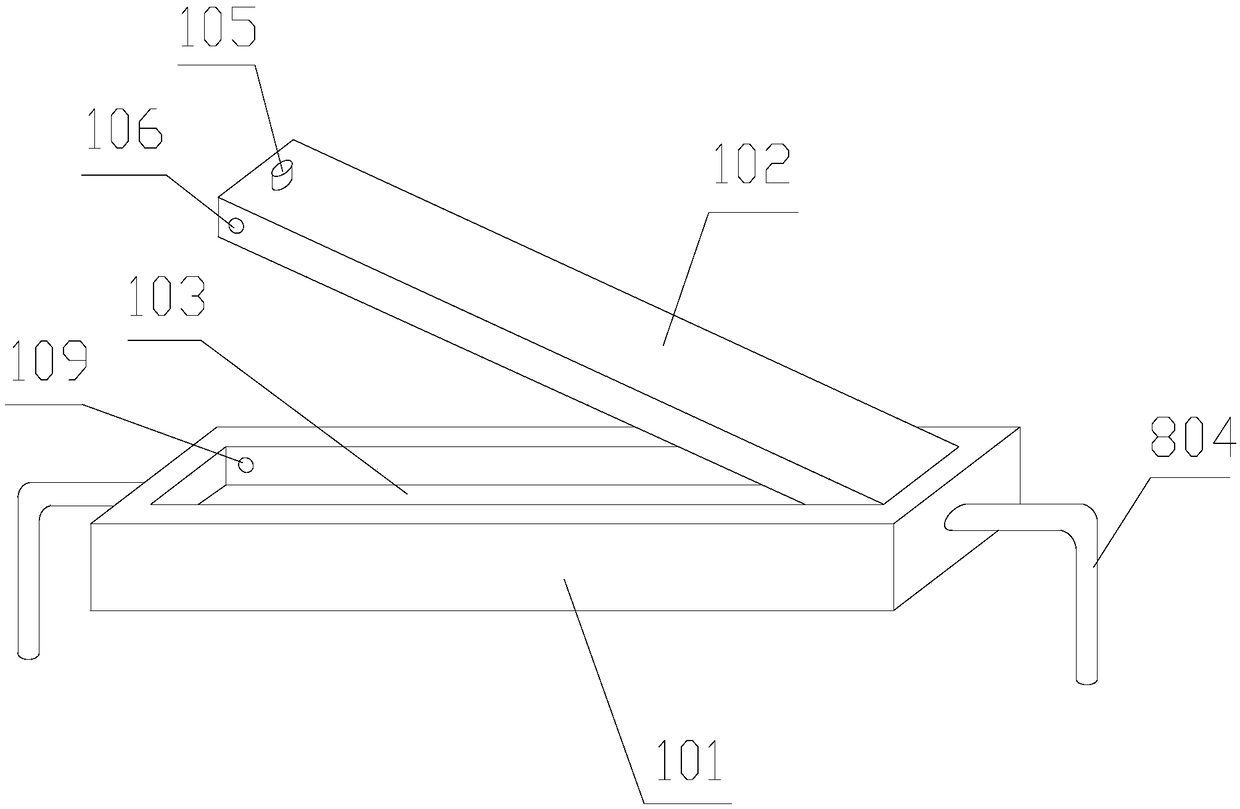

[0046] Further improvement on the basis of Embodiment 1, the positioning splint 1 includes a fixing plate 101 and a pressing plate 102, the upper surface of the fixing plate 101 is provided with a fixing groove 103 embedded in the holding pressing plate 102; the pressing plate 102 One end of the axial direction is connected to the inner wall of one end of the fixing groove 103 through a pin shaft, and the axial direction of the pin shaft is perpendicular to the axial direction of the pressure plate 102; the other axial end of the pressure plate 102 is detachably connected to the other axial end of the fixing groove 103; The pocket edge of the turnover bag 2 is pressed between the fixing groove 103 and the pressing plate 102.

Embodiment 3

[0048] Further improvement on the basis of Embodiment 2, the pressure plate 102 is provided with a mounting hole 104 on the surface away from the rotating connection end plate, and also includes an adjustment column 105, one axial end of the adjustment column 105 is inserted into the installation hole 104, and the other end is The protruding pressure plate 102 is set on the plate surface; the two sides of the pressure plate 102 are symmetrically provided with fixing holes 106, the fixing holes 106 communicate with the installation hole 104, and the axis direction of the fixing hole 106 is perpendicular to the axis direction of the installation hole 104; The fixing hole 106 is provided with a limit post 107, the limit post 107 is covered with a return spring 108, and the fixing hole 106 and the limit post 107 are provided with an adapted spring stopper, the spring stopper includes a stop ring plate 111 and positioning sleeve 112, the limit ring plate 111 is sleeved on the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com