Leakage guiding device of a B-type enclosure system of an LNG ship

A technology of LNG ship and diversion device, which is applied in ship components, ship construction, transportation and packaging, etc. It can solve problems such as structural cracks in B-type cargo tanks, increase the evaporation rate of liquid cargo, and seawater entering the cargo tank, so as to simplify the laying process, Effects of improving mechanical strength and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

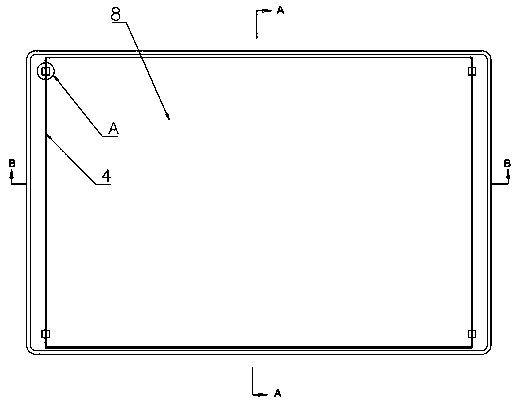

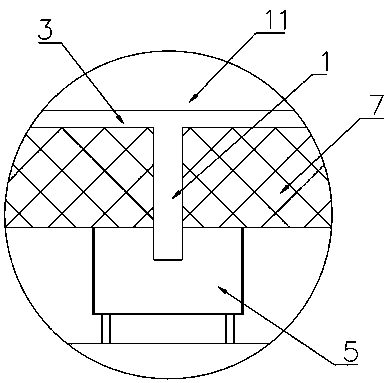

[0041] Example: such as Figure 1 to Figure 10 As shown, a leakage diversion device for a B-type containment system of an LNG ship includes a diversion mechanism, a diversion pipe 1, a lap plate 2 and a support mechanism, and the diversion mechanism includes a plurality of diversion devices with diversion grooves 3 Deflector, the plurality of deflectors are connected end-to-end on the upper surface of the B-type containment system insulation layer 7 of the LNG ship to form an annular liquid collection tank 4, and the annular liquid collection tank 4 and the collection device of the LNG ship 5 are connected through the diversion pipe 1, and two adjacent diversion plates are connected by a transition plate 6, and the lower surface of the diversion mechanism is connected with the upper surface of the insulating layer 7 of the B-type containment system of the LNG ship. Both sides of the diversion mechanism are connected to the splash screen 8 through the lap plate 2, and the upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com