concrete mixer

An agitator and concrete technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of not easy to carry, low mixing efficiency, large volume, etc. The effect of small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

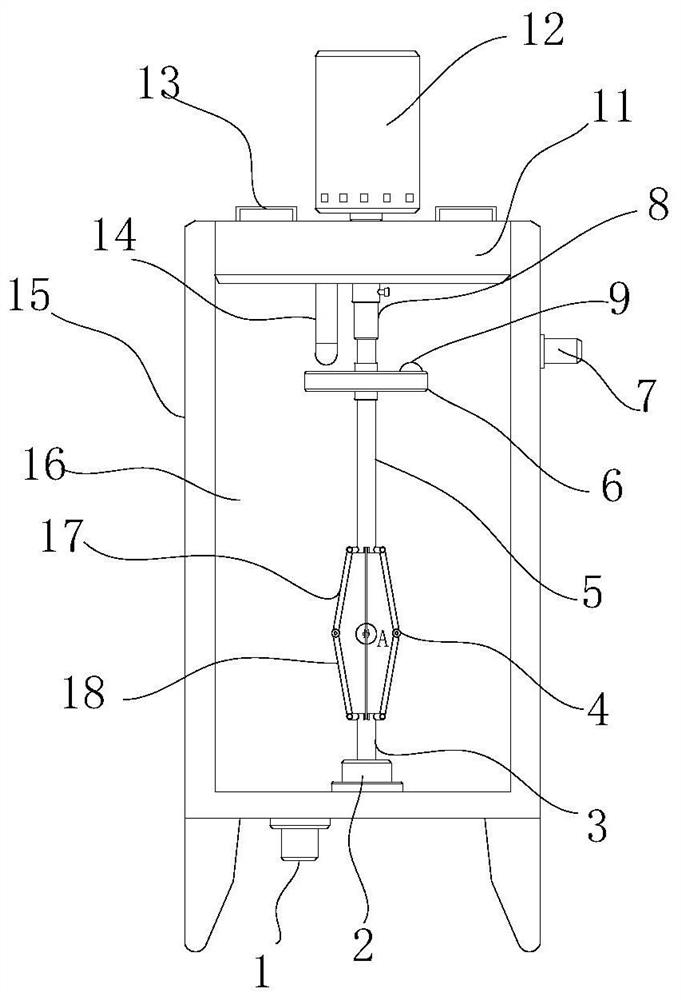

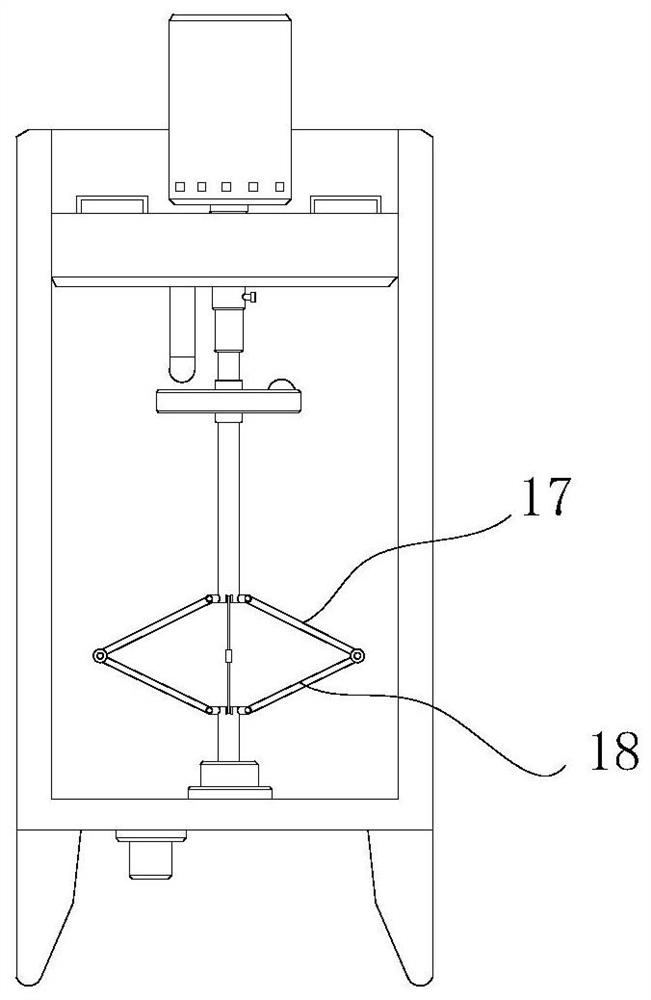

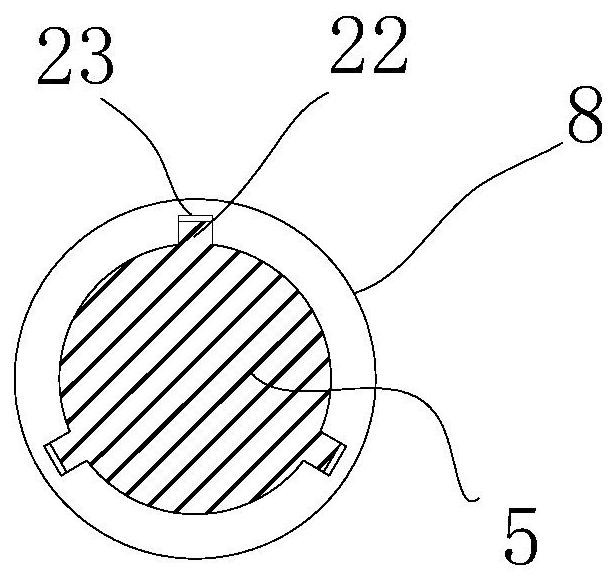

[0020] Such as figure 1 As shown, the concrete mixer includes a mixer shell 15, the upper end of the mixer shell 15 is open, the inner wall of the opening end is provided with an internal thread, and the opening end is threaded into a rotating cover 11, and the outer wall of the rotating cover 11 is engaged with the internal thread of the opening end. , a driving motor 12 is installed on the top of the rotating cover 11, and the motor shaft of the driving motor 12 is connected to a connecting rod 8 by a coupling, and a first rotating rod 5 is telescopically loaded into the connecting rod 8, and the first rotating rod 5 The top is telescopically loaded into the connecting rod 8;

[0021] The bottom of the first rotating rod 5 is provided with more than one first stirring blade 17 around the first rotating rod 5, and the other side of the first stirring blade 17 passes through the hinged structure 4 (such as Figure 4 shown) is hinged to a second stirring piece 18, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com