Horizontal type vibratory stirring machine with spiral vibration exciter

A technology of vibrators and mixers, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problems of poor bearing stress state, aggravated bearing wear, and complicated stress, so as to improve the mixing quality Good effect with efficiency, enhanced interface bonding strength, and bearing stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is further described:

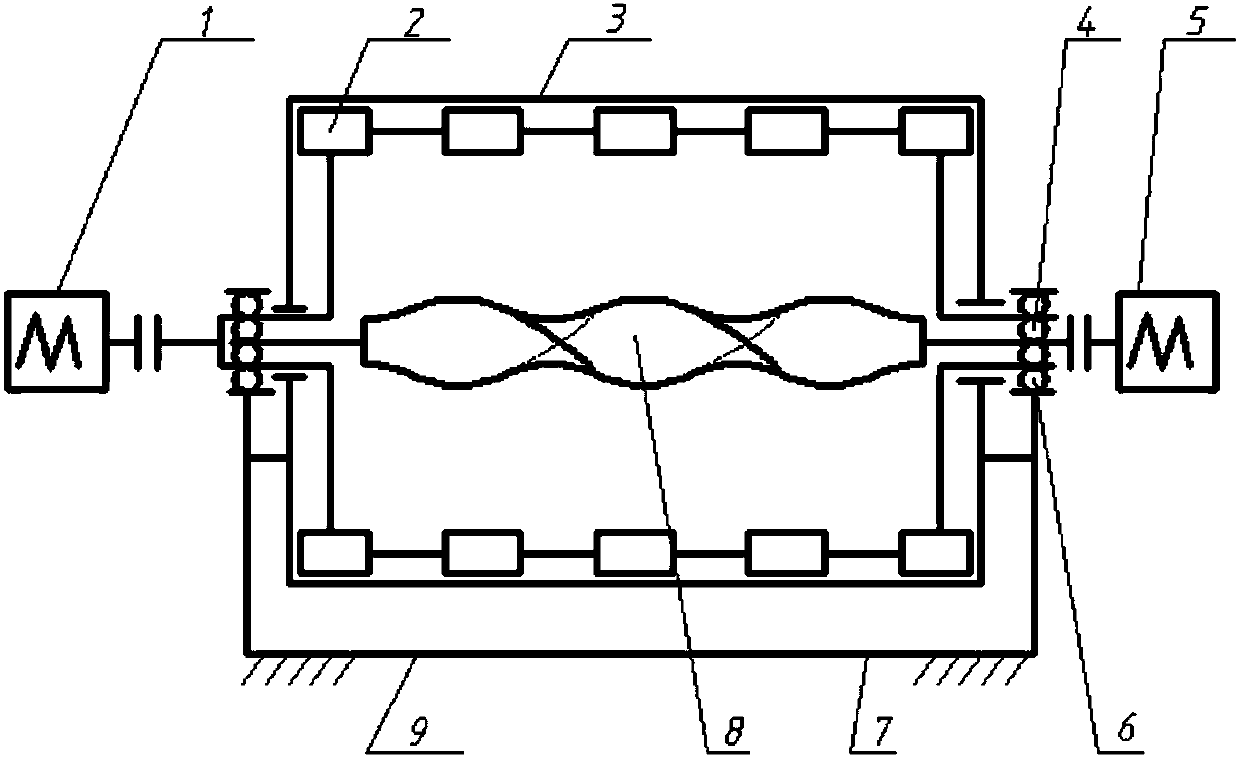

[0024] see Figure 1-Figure 3 , a horizontal vibration mixer with a spiral exciter, comprising a vibration power unit 5, a stirring power unit 1, a mixing drum 3, a stirring device 2, a frame 9 and a spiral vibration exciter 8; the mixing drum 3 is horizontally arranged, The vibration power device 5 and the stirring power device 1 are respectively arranged at both ends of the mixing drum 3 or at the same end of the mixing drum 3, the stirring device 2 is arranged in the mixing drum 3, and holes are arranged on both ends of the mixing drum 3 , the two ends of the stirring device 2 are supported on the frame 9 through the holes of the two ends of the mixing drum 3; the center of the stirring device 2 is provided with a helical vibrator 8; 5 connection, one end of the stirring device 2 is connected with the stirring power device 1;

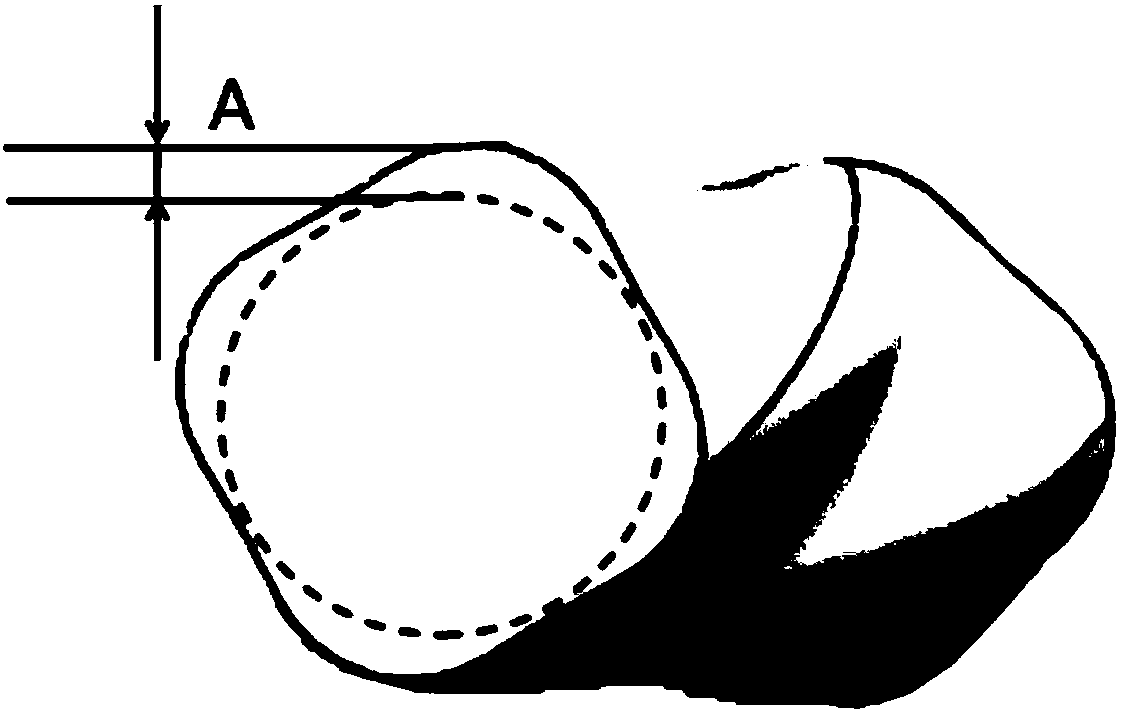

[0025] The spiral vibrator 8 is a polygon wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com