Design method of a two-dimensional thermal invisibility cloak with internal heat source in the concealed area

A design method and technology of internal heat source, applied in the field of heat transfer, can solve problems such as temperature increase, inability to design internal heat source, background temperature field disturbance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

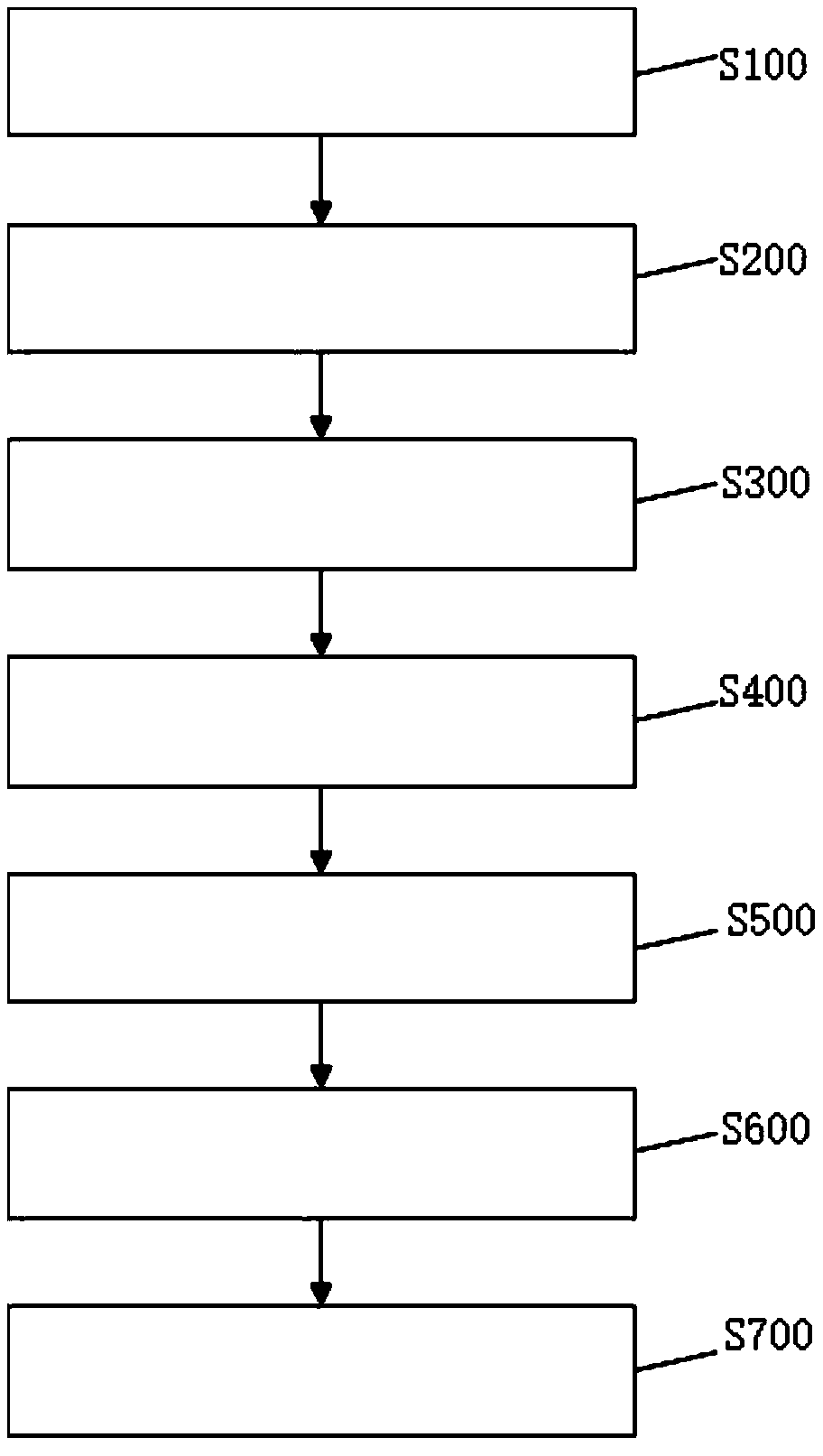

[0095] combine figure 1 , figure 2 A method for designing a two-dimensional thermal invisibility cloak with an internal heat source in the concealed area provided by an embodiment of the present invention includes the following steps:

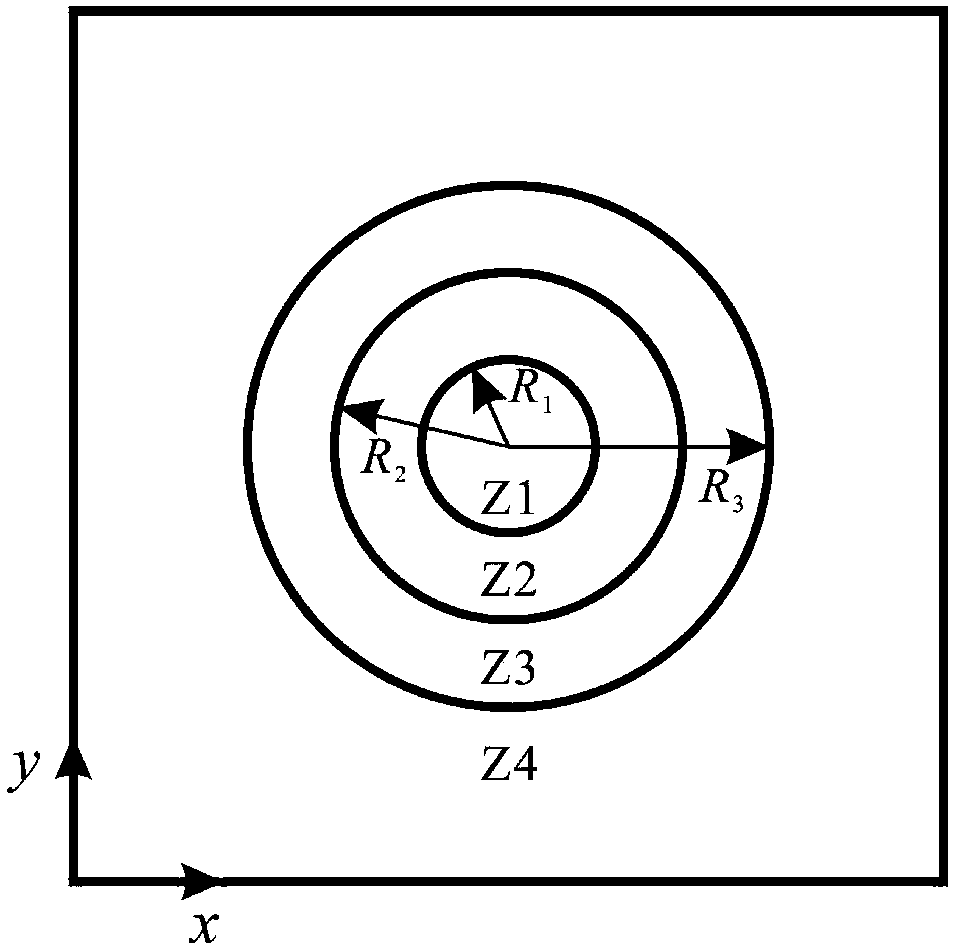

[0096] Step S100: Establish a two-dimensional coordinate system x-y and determine the area surrounded by the coordinate system as the design area, such as figure 1 shown. In this embodiment, the upper boundary temperature of the design area is set as T 1 , the lower boundary temperature setting T 2 , the left and right boundaries are adiabatic. The design area includes four areas, which are set as Z1, Z2, Z3 and Z4, and Z2, Z3 and Z1 are arranged concentrically. Among them, the Z1 area is the hidden area, and the area radius is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com