Tunnel full-section pre-reinforcement operation vehicle

A working vehicle and full-section technology, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of reduced equipment supporting capacity and mechanization degree, inability to lead engineering technology revolution, low construction technology content, etc., and achieve equipment manufacturing Convenience, cost-effectiveness, and easy-to-move effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

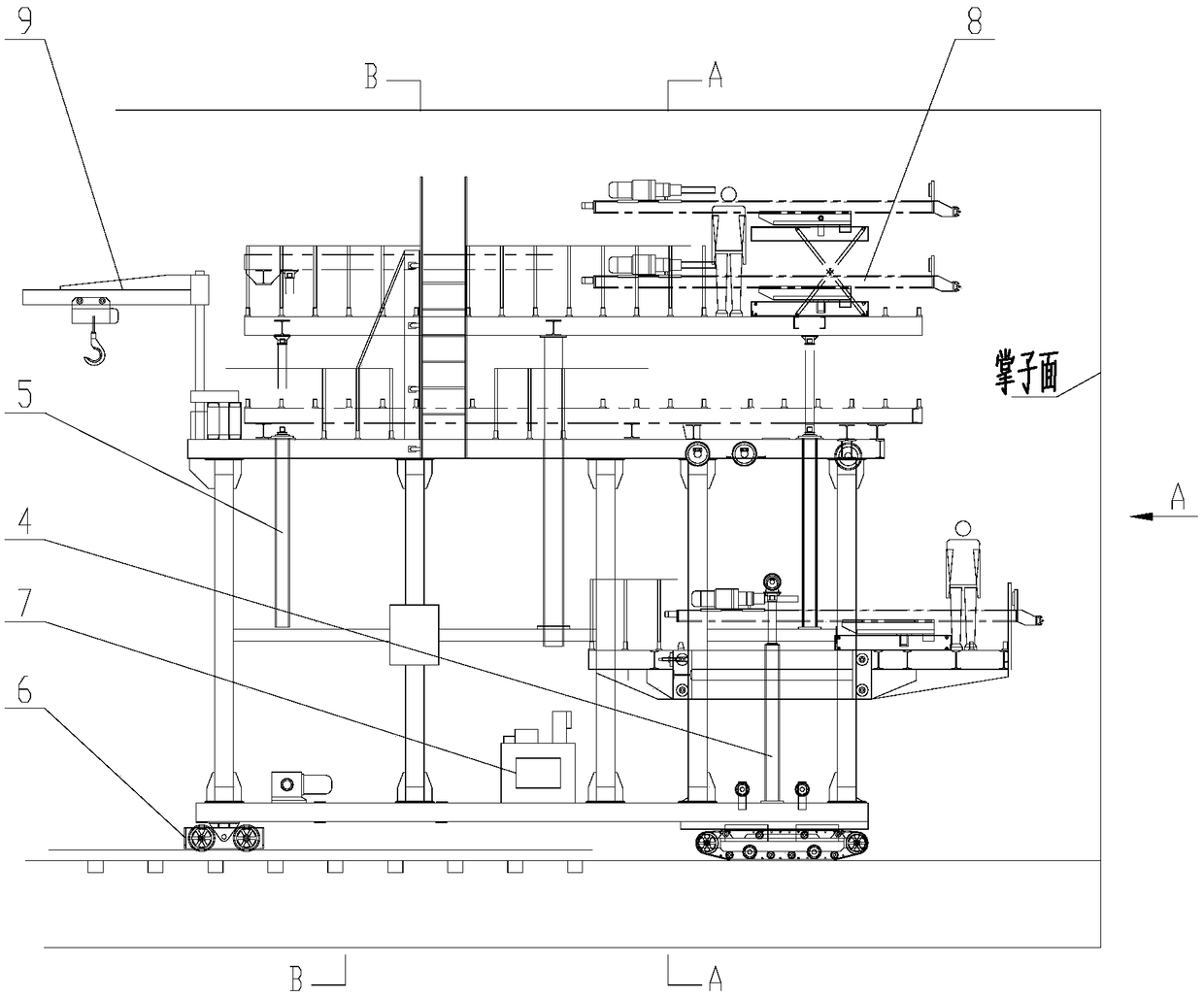

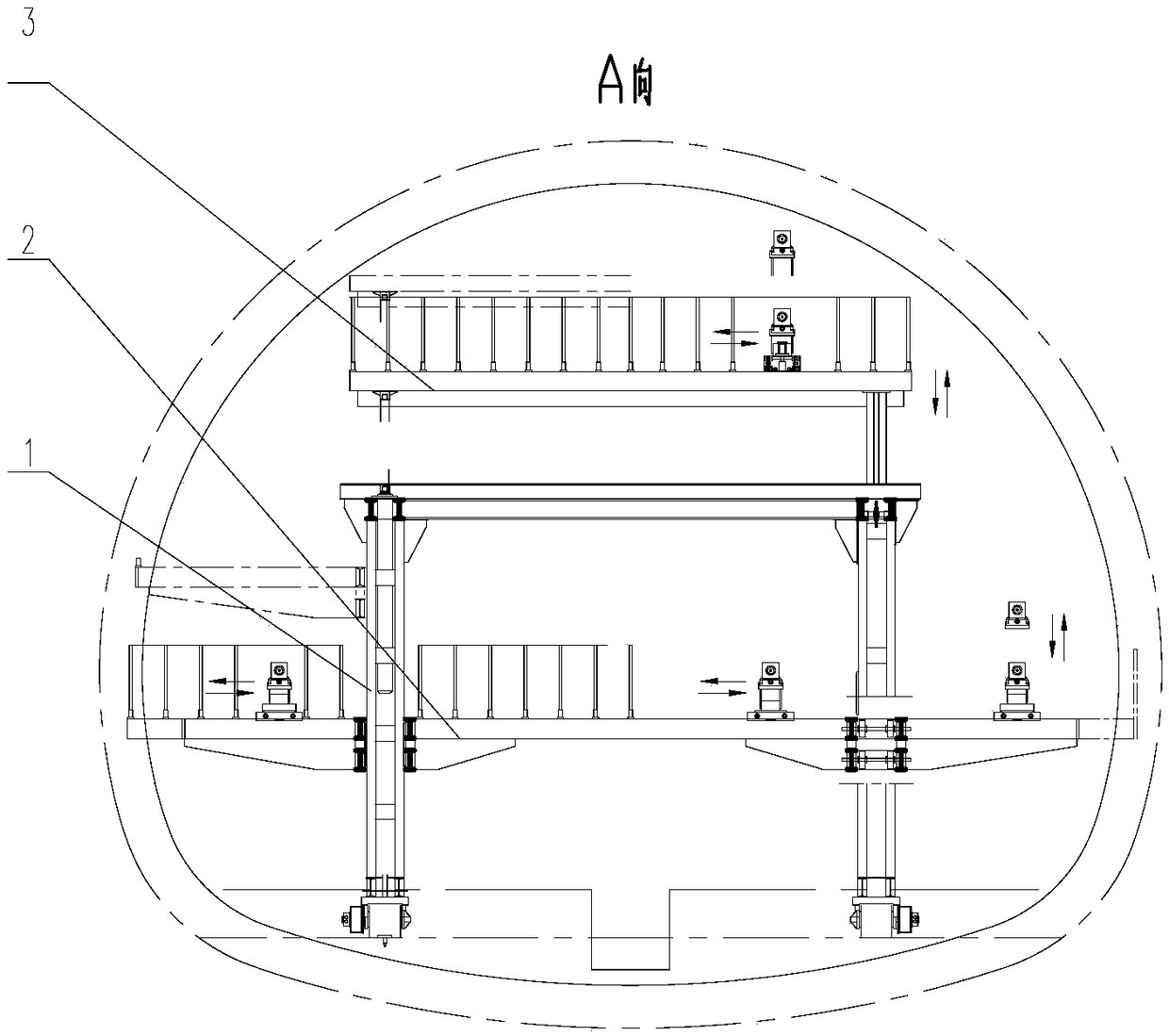

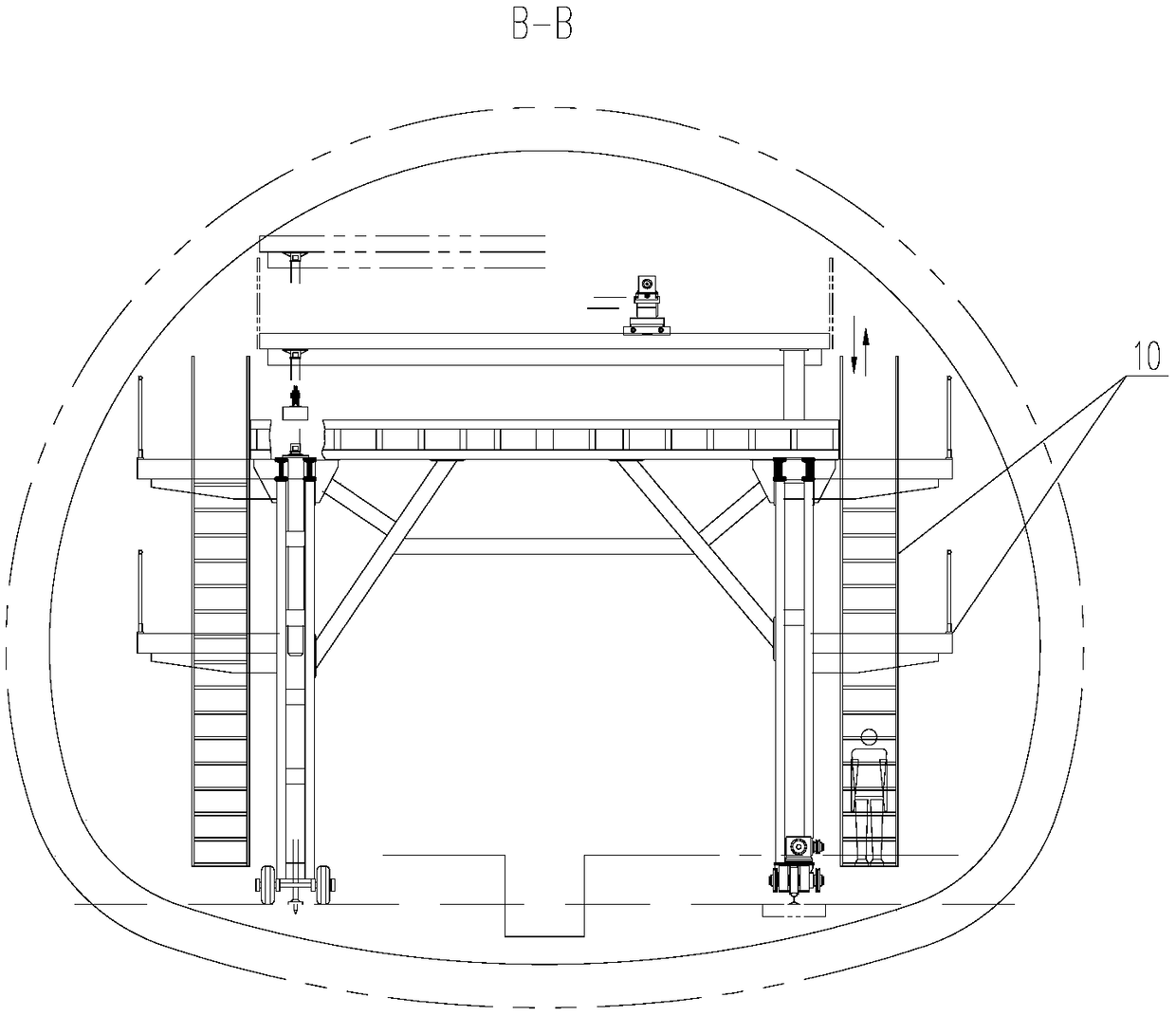

[0063] like Figure 1-3 As shown, the tunnel full-section pre-reinforcement vehicle of the present invention includes a trolley frame 1, a main lifting platform 2, a top lifting platform 3, a main platform lifting system 4, a top platform lifting system 5, a walking drive system 6, and a main control system. System 7 and several drilling rigs 8 . The main platform lifting system 4 and the top platform lifting system 5 are all installed on the trolley frame 1. The main platform lifting system 4 is also connected with the main lifting platform 2 to drive the main lifting platform 2 to move up and down. The top platform lifting system 5 is also connected with the top platform. The lifting platforms 3 are connected to drive the top lifting platform 3 to move up and down; the main lifting platform 2 and the top lifting platform 3 are provided with guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com