Rail-mounted dust suppression device used for construction site

A construction site, track-type technology, applied in cleaning methods, using liquid separating agents, road cleaning, etc., can solve problems such as increasing the labor intensity of operators, inconvenient movement of spraying devices, and impact on the health of construction workers, etc. performance, preventing derailment, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

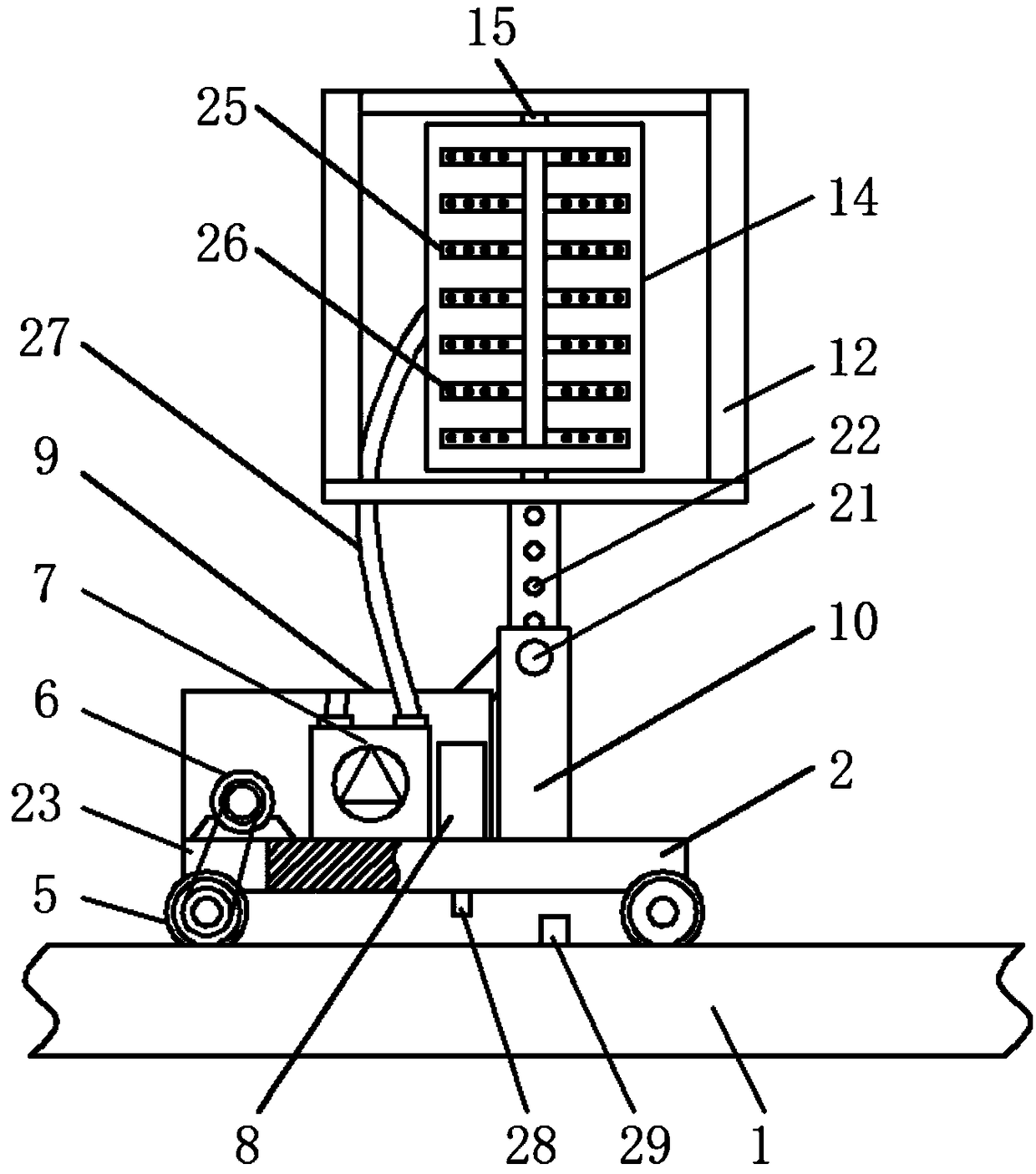

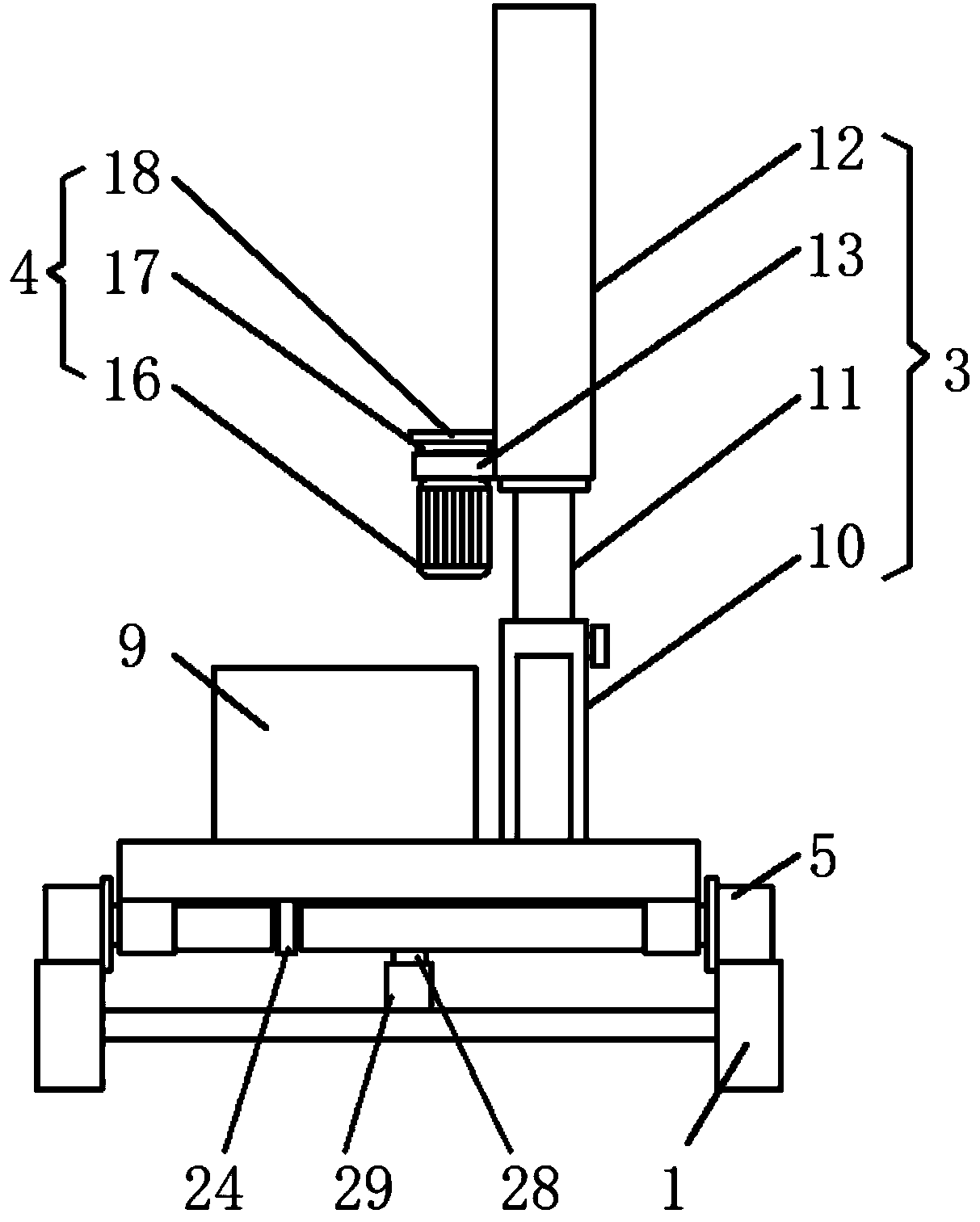

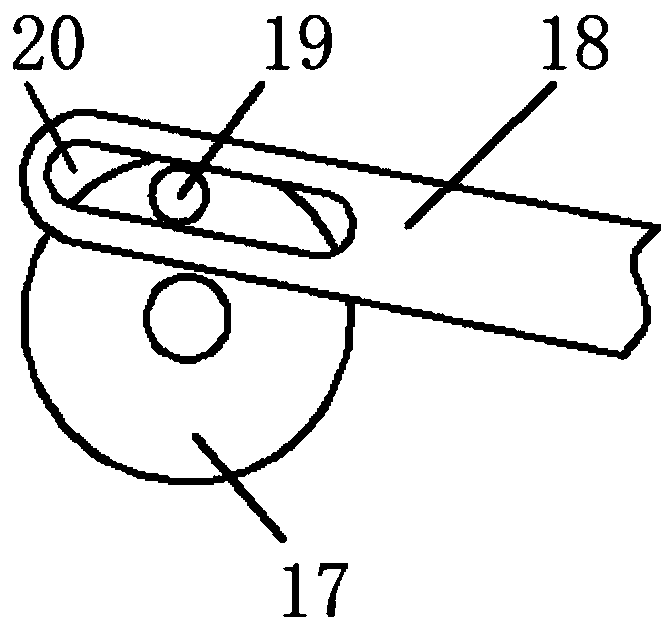

[0021] see Figure 1-3 The present invention provides a technical solution: a track 1 type dust suppression device for a construction site, including a track 1, a base 2, a support frame 3 and a swing mechanism 4, the base 2 is located on the surface of the track 1 and is slidably connected with the track 1 , the surface of the base 2 is fixedly connected with a support frame 3, and the side wall of the support frame 3 is fixedly connected with a swing mechanism 4; 1 contact connection, the upper surface of the base 2 is fixedly connected with the first motor 6, the water pump 7, the PLC controller 8 and the protective cover 9, and the first motor 6, the water pump 7 and the PLC controller 8 are located in the protective cover 9 The support frame 3 includes a sleeve 10, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com