Comb handling trolley and synchronous aligning device thereof

A technology of comb teeth and racks, which is applied in the field of comb-tooth handling trolleys and their synchronous push-up devices, can solve the problems of small storage volume and the gradual elimination of small garages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiment of the comb-tooth carrying trolley of the present invention:

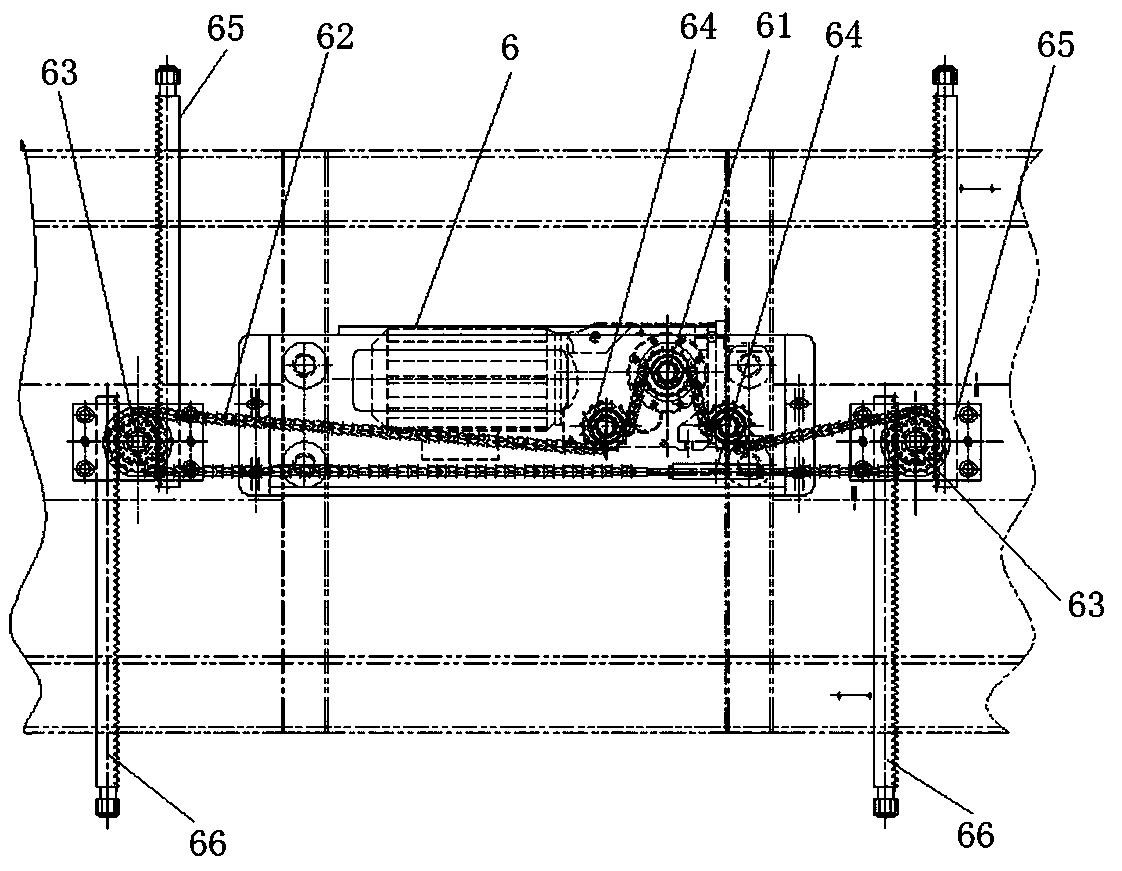

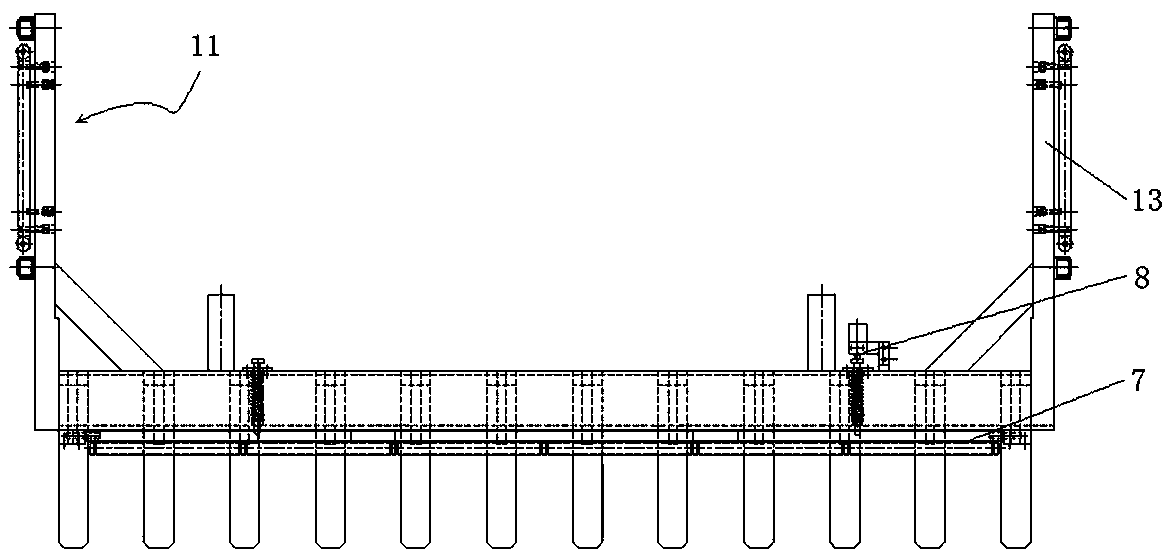

[0031] The comb-tooth handling trolley of the present invention comprises a synchronous straightening device, and the specific structure of the synchronous straightening device is as follows: Figure 1 to Figure 7As shown, it includes a frame 5, a rear push mechanism 2, a front push mechanism 3, a rear comb assembly 1 for lifting the rear wheels of the vehicle and a front comb assembly 4 for lifting the front wheels of the vehicle.

[0032] The rear comb assembly 1 includes a first rear comb frame 11 and a second rear comb frame 12 arranged symmetrically. The front comb assembly 4 includes a first front comb frame 41 and a second front comb frame 42 arranged symmetrically.

[0033] The first rear comb frame 11 and the second rear comb frame 12 are all slidably installed on the frame 5, and the push-back mechanism 2 is used to drive the first rear comb frame 11 and the second rear comb frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com