Equipment for laying curing agent flooring materials

A floor material and curing agent technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of manually adjusting the output volume and the inability to change the spraying volume, so as to increase the laying efficiency and evenly lay the materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

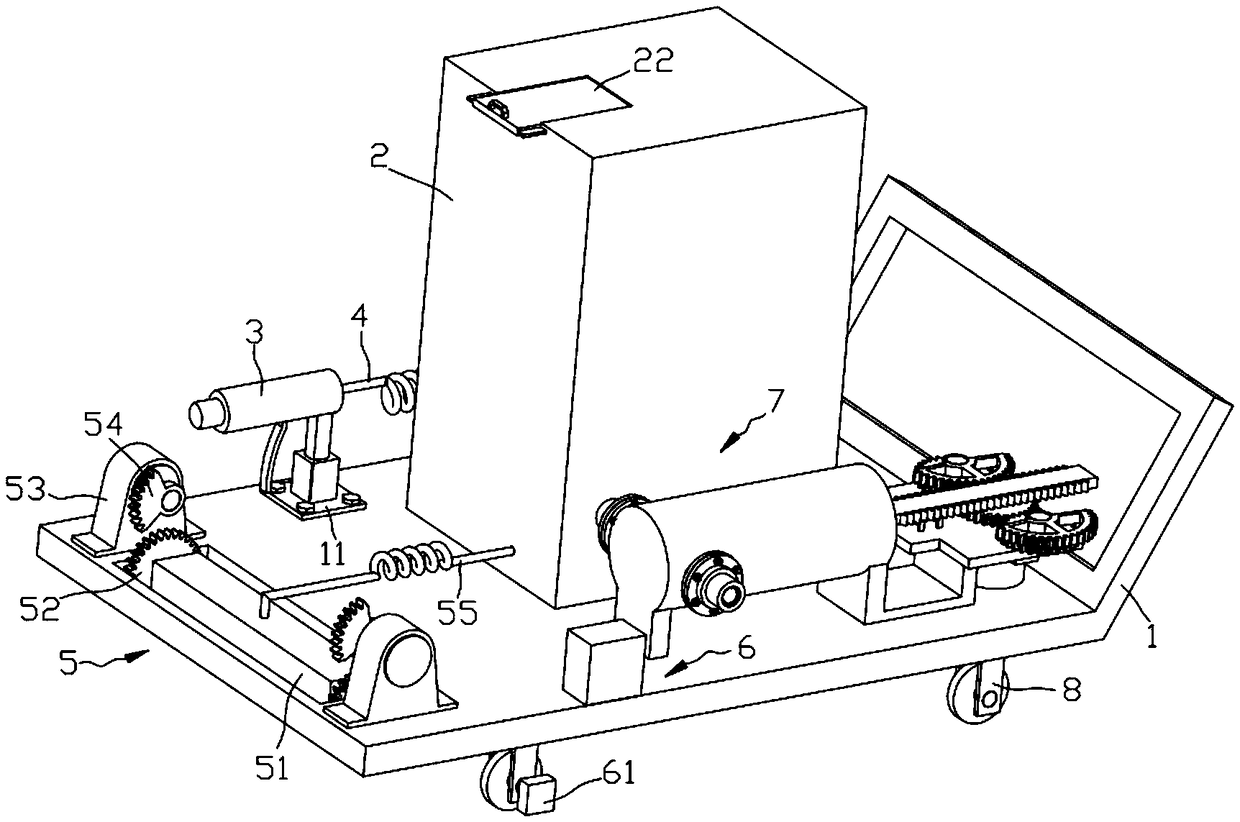

[0033] see Figure 1 to Figure 9 , the present invention provides a technical solution:

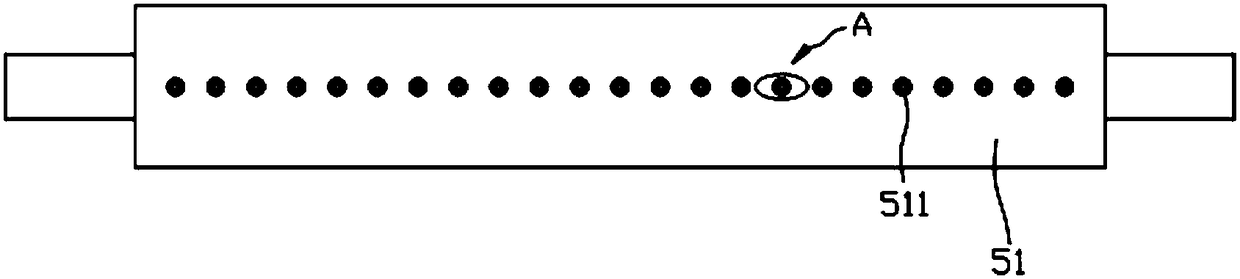

[0034] A curing agent floor material laying equipment, including a vehicle frame 1, a material box 2, a spray gun 3, a hose I 4, a laying mechanism 5, a control unit 6, a pressurizing mechanism 7 and wheels 8, and the bottom of the vehicle frame 1 is equipped with four 8 wheels, of which:

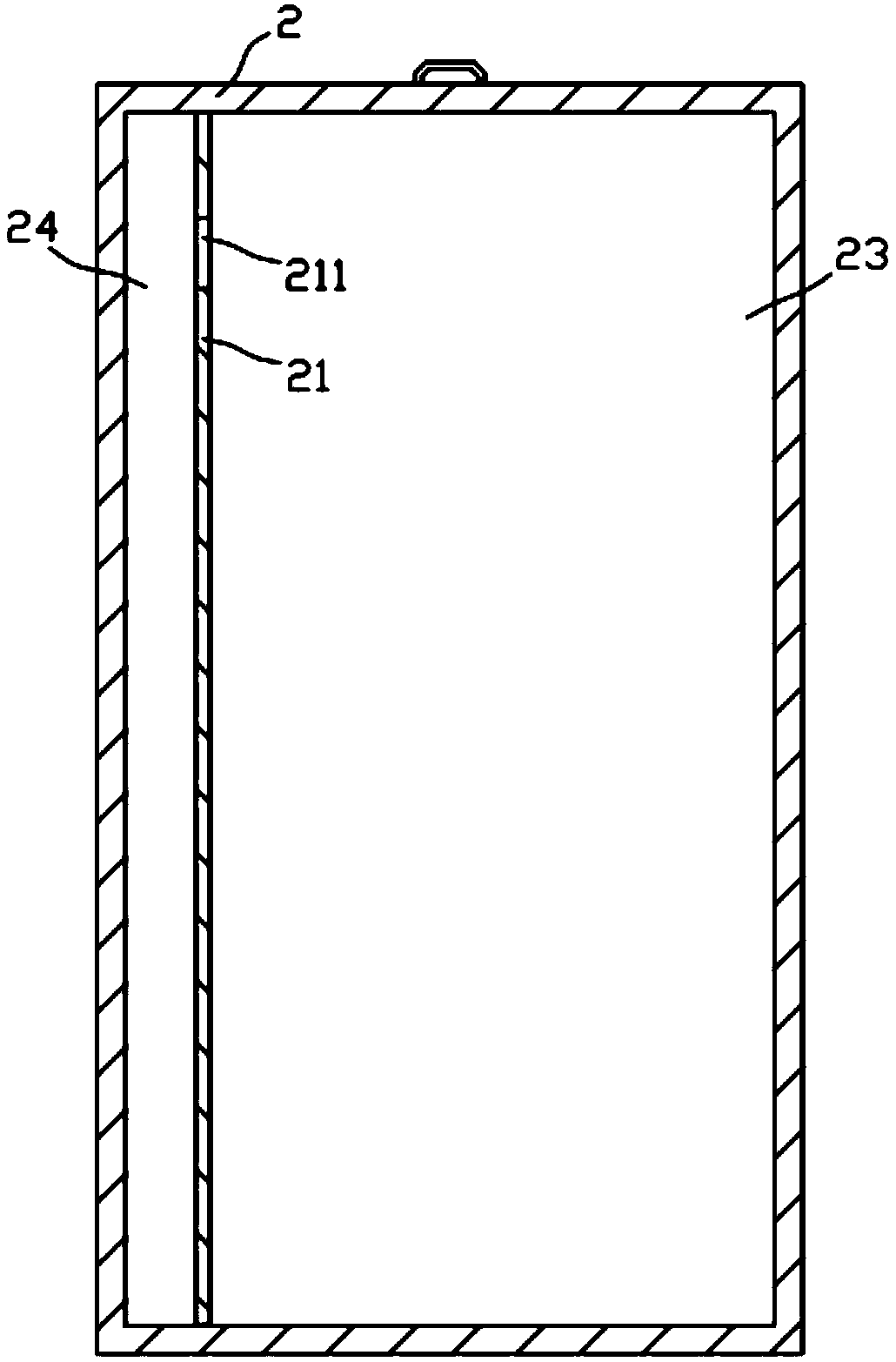

[0035] The material box 2 is fixedly installed on the vehicle frame 1, and a partition 21 is arranged in the material box 2, and an air outlet 211 is provided on the partition 21, wherein the partition divides the material box 2 into a material cavity 23 and an air cavity 24, and the material cavity 23 communicates with the air chamber 24 through the air outlet 211 on the partition 21, and a pumping plate 22 is movably installed on the material box 2, wherein the pumping plate 22 is located above the material chamber 23, and between the pumping plate 22 and the material box 2 There is a sealing strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com