A low-rise fully assembled concrete shear wall structure system

A concrete shear wall and full assembly technology, which is applied in building construction and construction, can solve the problems of low assembly rate, shortened construction period, and large wet work volume, and achieves the advantages of convenient structural connection, shortened construction period, and improved construction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

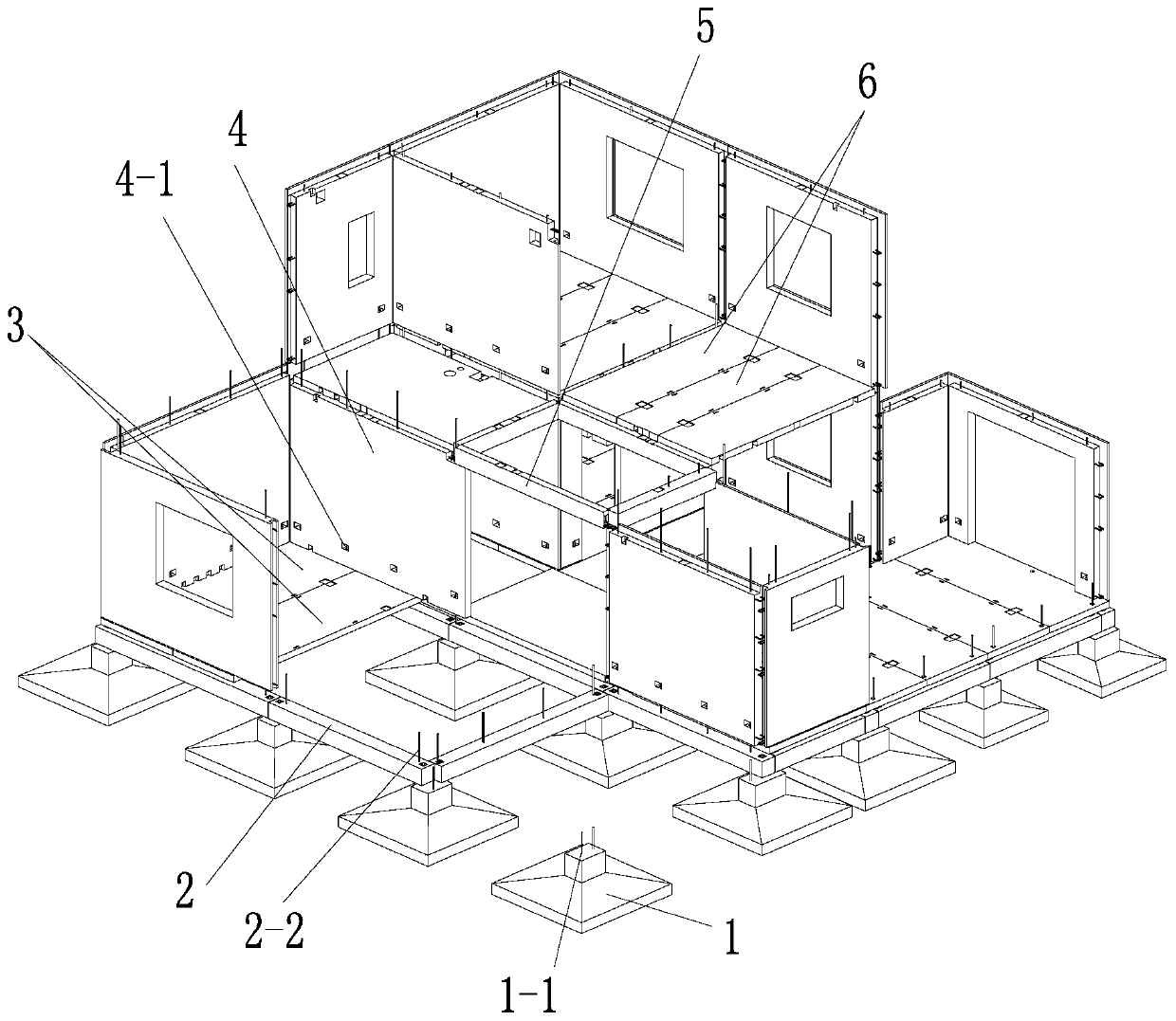

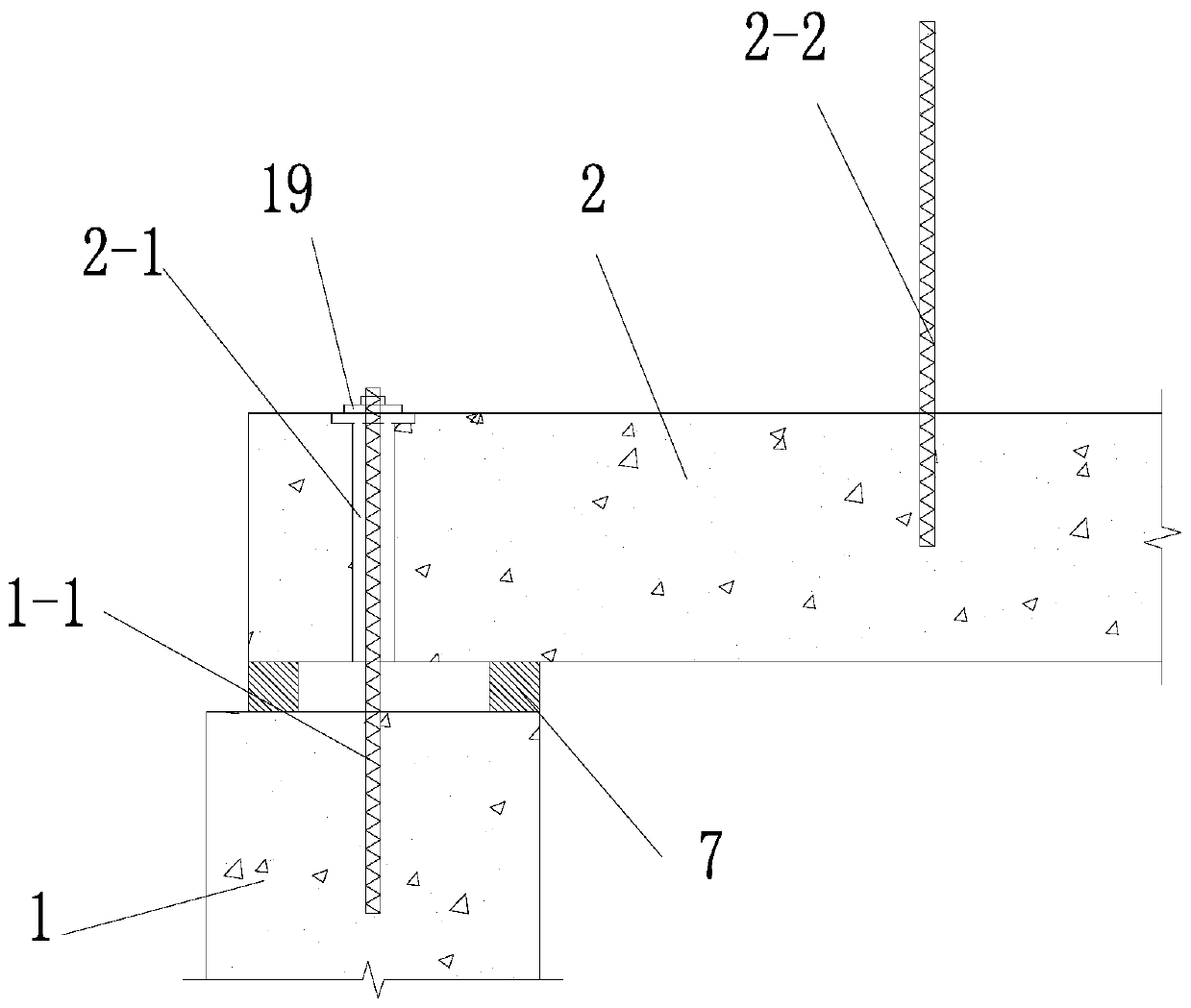

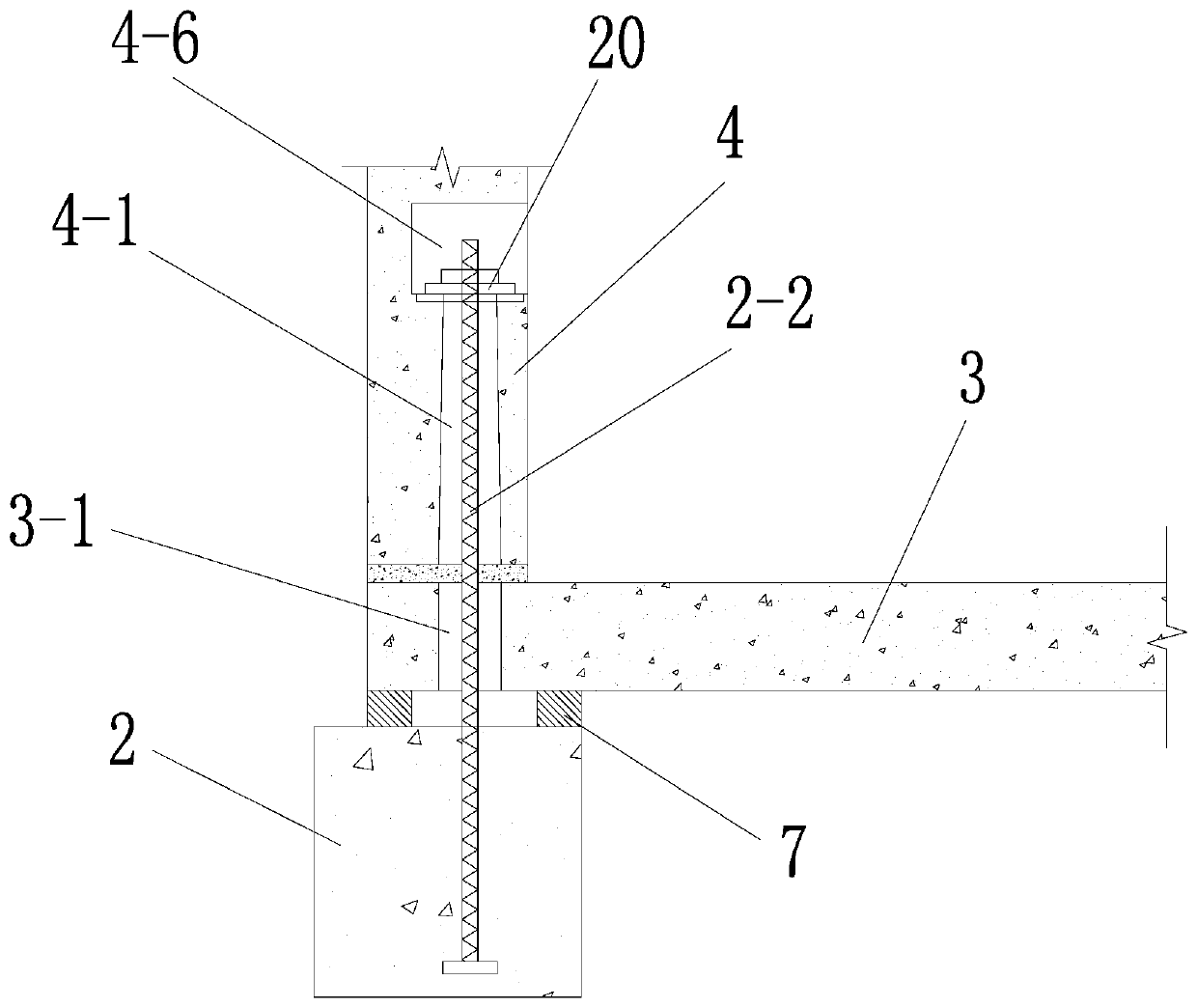

[0044] Such as Figure 1 to Figure 8 As shown, the present invention includes a prefabricated independent foundation 1, a prefabricated ground beam 2 installed on the prefabricated independent foundation 1, a prefabricated bottom plate 3 installed on the prefabricated ground beam 2 and a prefabricated shear vertically installed on the prefabricated bottom plate 3 The force wall 4, and the prefabricated beam 5 erected between two opposite prefabricated shear walls 4 and the prefabricated floor slab 6 laid on the prefabricated shear wall 4 and the prefabricated beam 5, the top of the prefabricated independent foundation 1 is pre-buried There is a first pre-embedded steel bar 1-1, the two ends of the prefabricated ground beam 2 are provided with a first pouring hole 2-1 for the first pre-embedded steel bar 1-1 to pass through, and the top of the prefabricated ground beam 2 is pre-buried with A plurality of second pre-embedded steel bars 2-2, the prefabricated floor 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com