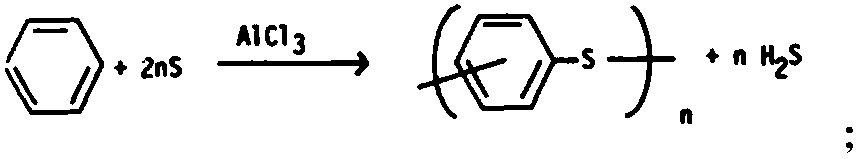

Method for preparing polyphenylene sulfide from benzene and sulfur

A technology of polyphenylene sulfide and polyphenylene sulfide resin, which is applied in the production process of polyphenylene sulfide, can solve the problems of high crystallinity of polyphenylene sulfide, difficulty in processing, limitation of application field and use range, etc., and achieve washing The effect of less frequency, improved production efficiency, and expanded application field and use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

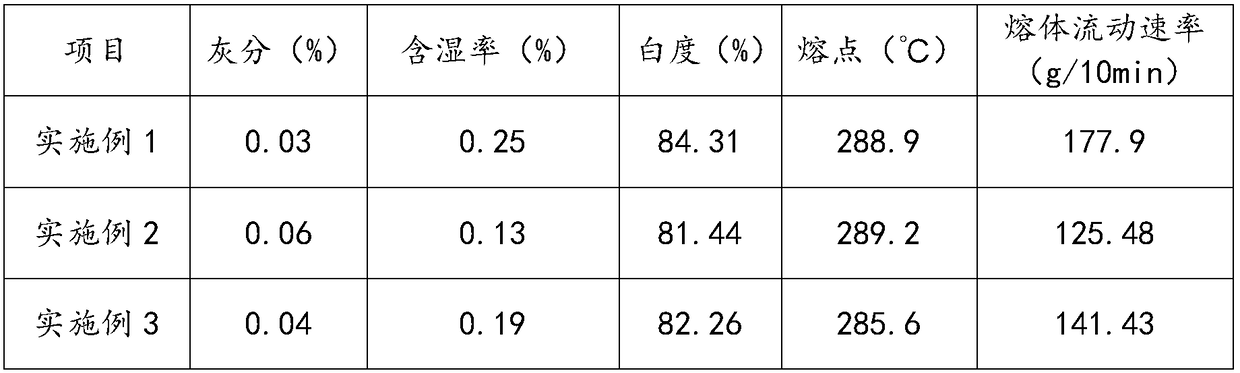

Embodiment 1

[0032] A method for preparing polyphenylene sulfide with benzene and sulfur as raw materials, comprising the following steps:

[0033] (1) Add 1 mol of 1,2,4-trichlorobenzene and 0.04 mol of nano-copper oxide into the reactor in sequence, start stirring, then add 1 mol of sulfur, and continue stirring until a uniform suspension is formed in the reactor;

[0034] (2) Add 0.51mol benzene to the suspension formed in step (1), adjust the temperature in the reactor to 80°C at a heating rate of 5-6°C / min, and react at a constant temperature for 1.5h;

[0035] (3) Adjust the temperature in the reactor to 130°C at a heating rate of 5-6°C / min, and react at a constant temperature for 4 hours;

[0036] (4) Adjust the temperature in the reactor to be lower than 40°C, send the materials in the reactor to a centrifuge for solid-liquid separation to obtain crude polyphenylene sulfide resin, and send the separated liquid to the mother liquor temporary storage tank for recycling use;

[0037...

Embodiment 2

[0039] A method for preparing polyphenylene sulfide with benzene and sulfur as raw materials, comprising the following steps:

[0040] (1) Add 1 mol of 1,2,4-trichlorobenzene and 0.03 mol of nano-aluminum chloride to the reactor in sequence, start stirring, then add 1 mol of sulfur, and continue stirring until a uniform suspension is formed in the reactor;

[0041] (2) Add 0.51mol benzene to the suspension formed in step (1), adjust the temperature in the reactor to 90°C at a heating rate of 5-6°C / min, and react at a constant temperature for 1.5h;

[0042] (3) Adjust the temperature in the reactor to 150°C at a heating rate of 5-6°C / min, and react at a constant temperature for 4 hours;

[0043] (4) Adjust the temperature in the reactor to be lower than 40°C, send the materials in the reactor to a centrifuge for solid-liquid separation to obtain crude polyphenylene sulfide resin, and send the separated liquid to the mother liquor temporary storage tank for recycling use;

[0...

Embodiment 3

[0046]A method for preparing polyphenylene sulfide with benzene and sulfur as raw materials, comprising the following steps:

[0047] (1) Add 1mol 1,2,4-trichlorobenzene and 0.05mol nano-copper iodide to the reaction kettle in turn, start stirring, then add 1mol sulfur, and continue stirring until a uniform suspension is formed in the reaction kettle;

[0048] (2) Add 0.52mol of benzene to the suspension formed in step (1), adjust the temperature in the reactor to 95°C at a heating rate of 5-6°C / min, and react at a constant temperature for 1.5h;

[0049] (3) Adjust the temperature in the reactor to 160°C at a heating rate of 5-6°C / min, and react at a constant temperature for 4 hours;

[0050] (4) Adjust the temperature in the reactor to be lower than 40°C, send the materials in the reactor to a centrifuge for solid-liquid separation to obtain crude polyphenylene sulfide resin, and send the separated liquid to the mother liquor temporary storage tank for recycling use;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com