Bottle opening dispenser

A liquid dispenser and liquid outlet technology, applied in the field of liquid treatment, can solve problems such as poor accuracy, operator's hand joint strain, mental fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

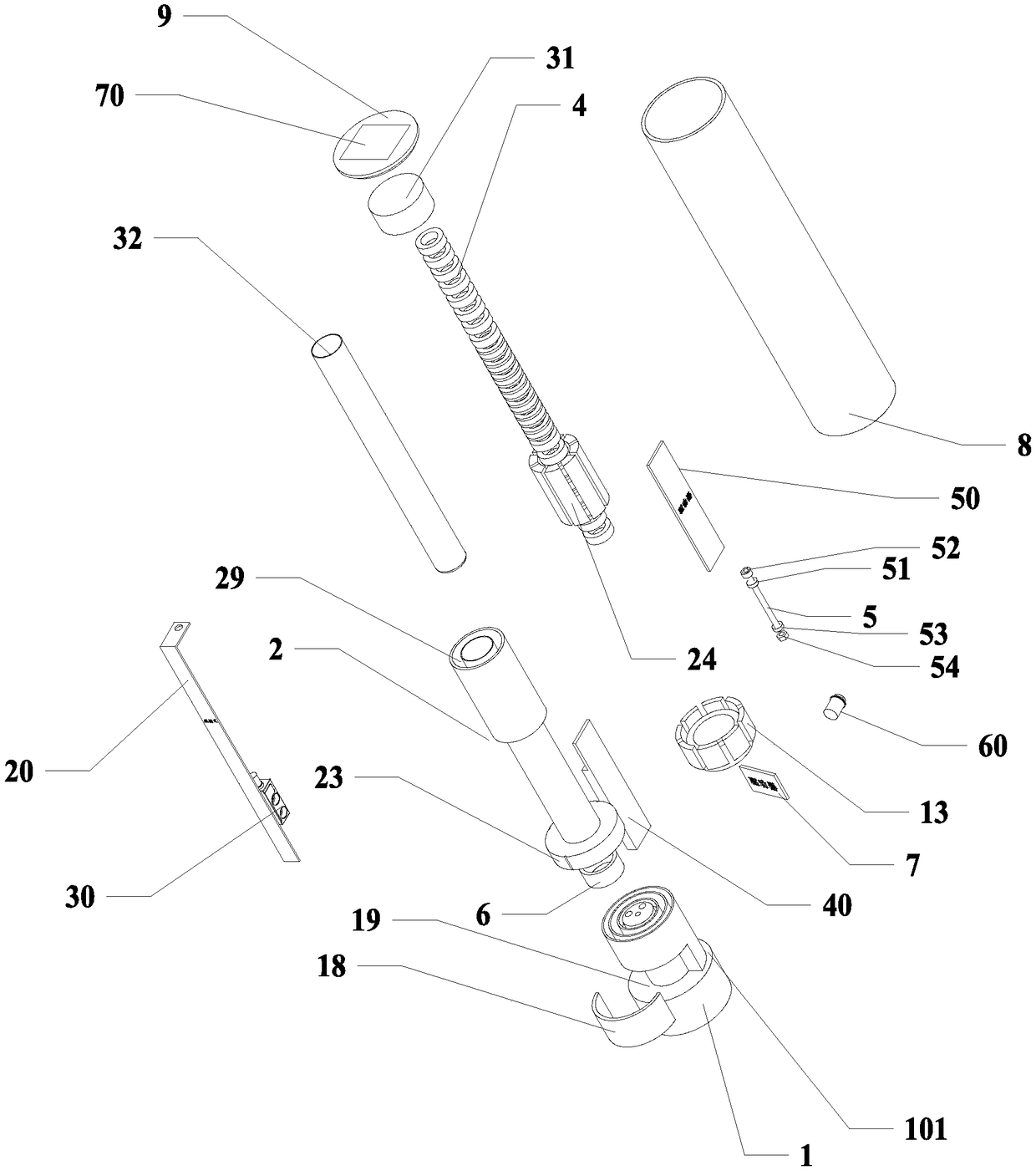

[0049] Attached below Figure 1-11 The technical solutions of the present invention are further described through specific implementation methods.

[0050] The invention provides a bottle mouth dispenser.

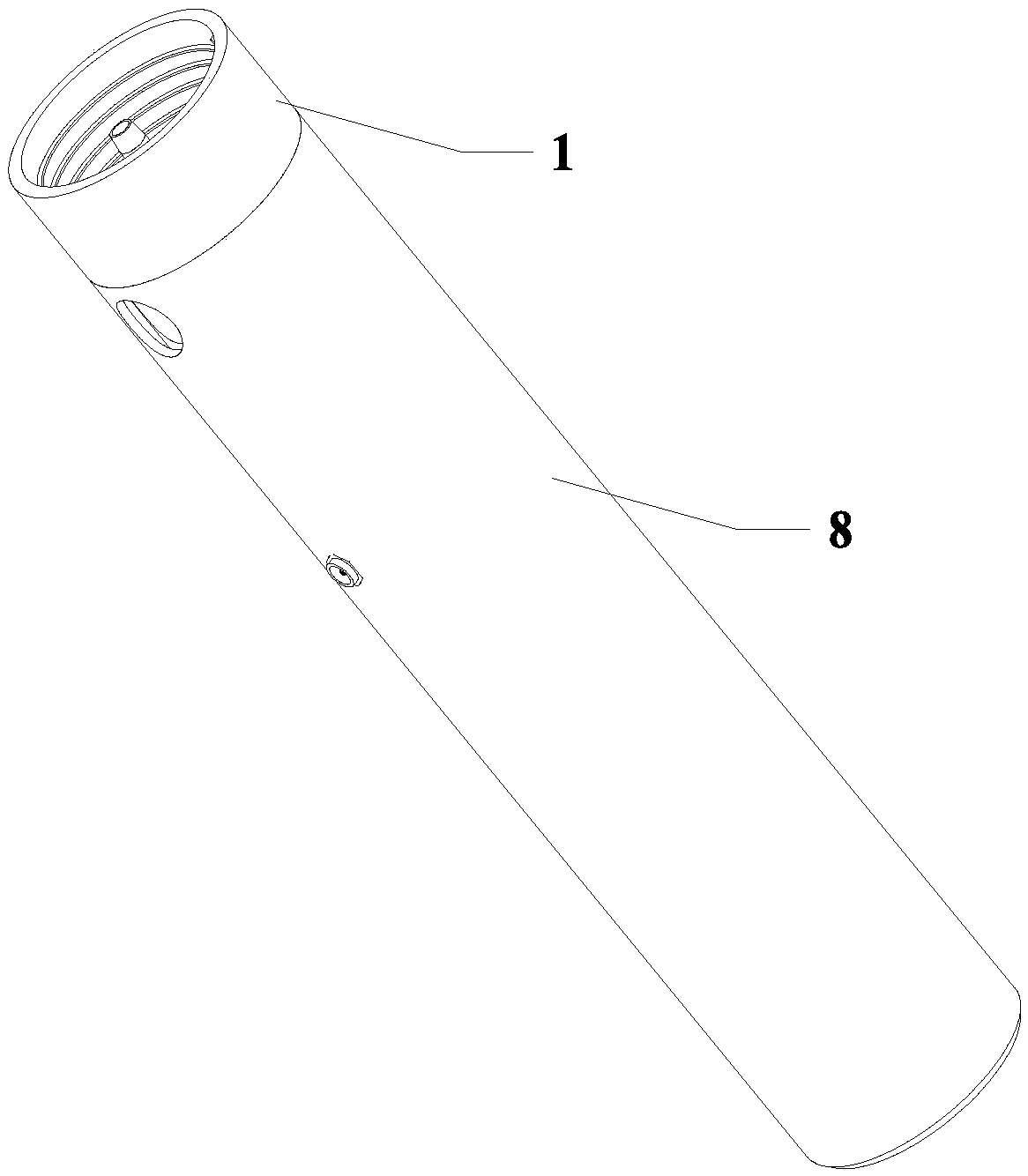

[0051] A bottle dispenser, comprising a base 1, a piston pump body 2 and a piston rod 3, the base 1 is arranged at the bottom of the piston pump body 2, and the piston rod 3 is arranged inside the piston pump body 2;

[0052] The base 1 is provided with a first liquid suction hole 11 and a first liquid outlet hole 12, and the bottom of the piston pump body 2 is provided with a second liquid suction hole 21 and a second liquid outlet hole 22;

[0053] The peripheral side of the base 1 is embedded with a rotary motor stator 13, and the bottom peripheral side of the piston pump body 2 is provided with a rotary motor rotor 23;

[0054]The upper peripheral side of the piston pump body 2 is provided with a lifting motor stator 24, and the high direction of the piston rod 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com