Guide rail conveying device and use method thereof

A technology for handling devices and guide rails, which is applied in transportation and packaging, ship parts, ships, etc. It can solve the problems of difficult handling and positioning of guide rails, and achieve the effects of convenient transportation and installation, enhanced stability, and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

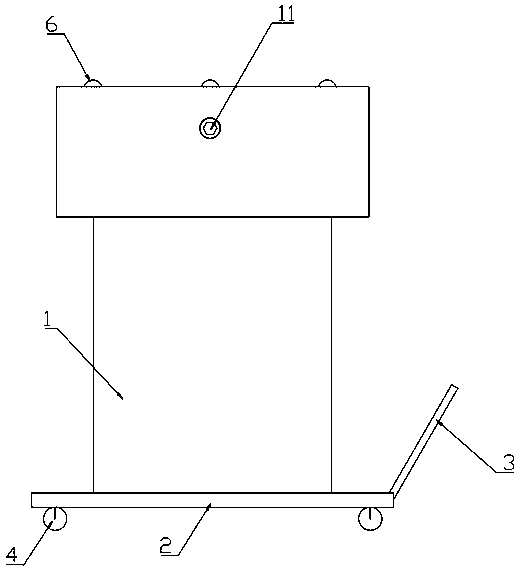

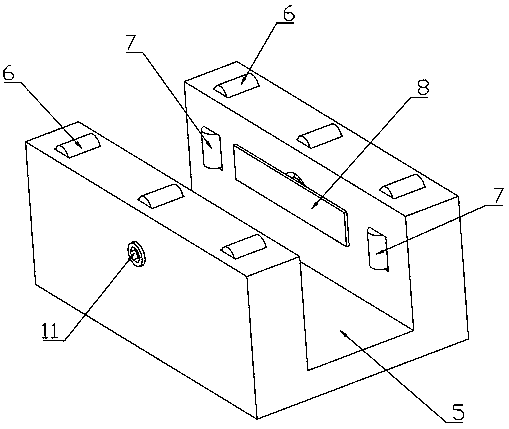

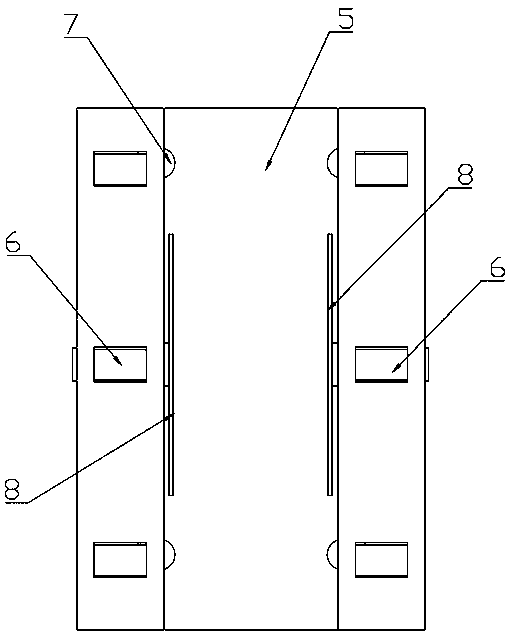

[0047] Embodiment 1: as Figure 1 to Figure 6 As shown, a kind of guide rail handling device comprises a trolley, a lifting mechanism 1 and a top carrying mechanism, and the trolley comprises a base plate 2 and a handle 3, and the handle 3 is arranged on one side of the base plate 2, and the lower surface of the base plate 2 is The four corners of each are provided with a caster 4 with brakes, the lifting mechanism 1 is arranged on the upper surface of the base plate 2, and the top carrying mechanism is arranged on the top of the lifting mechanism 1, and the top carrying mechanism includes a bearing groove 5 and Two locking mechanisms, the tops of the two side walls of the bearing groove 5 are provided with more than two horizontal rollers 6, the central axes of the horizontal rollers 6 are perpendicular to the bearing groove 5, and the bearing groove 5 has two The inner sides of the side walls are provided with more than two vertical rollers 7, and a horizontal threaded hole ...

Embodiment 2

[0073] Embodiment 2: As a kind of improved scheme of embodiment 1, such as Figure 7 As shown, as a further preference, the handling device further includes an upper cover 14 , the upper cover 14 covers the top carrying mechanism, and the upper cover 14 and the top carrying mechanism are connected by a lock 15 mechanism.

[0074] The handling device also includes an upper cover 14, which improves the flatness of the upper end of the top bearing mechanism and facilitates the operator to work on the upper cover 14, thereby increasing the function of the device.

[0075] Preferably, there are four locking buckles 15, and the four locking buckles 15 are respectively arranged at the four corners of the top carrying mechanism.

[0076] The upper cover 14 and the top carrying mechanism are connected by four locks 15, thereby enhancing the stability of the connection between the top carrying mechanism and the upper cover 14, and improving the safety of the operator standing on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com