Preparation method for alcohol-free fountain solution

A technology of alcohol dampening and preparation steps, applied in the field of printing, can solve the problems of poor stability of alcohol-free dampening solution, increased auxiliary time, and high frequency of replacing dampening solution and cleaning water hopper, and achieves good detergency and improved detergency. The effect of dispersion uniformity and adhesion enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

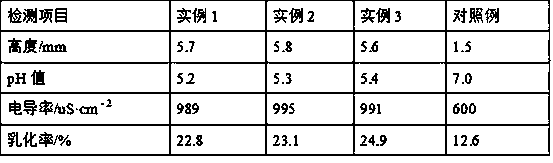

Examples

example 1

[0020] Mix sodium dodecylbenzene sulfonate and lauryl amidopropyl betaine evenly at a mass ratio of 1:1 to obtain a mixture. At a rotational speed of 30r / min, mix NEUF-160h and D114 at a mass ratio of 1:1:5 Add it into the mixture and stir for 30 minutes to obtain a compound surfactant; mix 0.2mol / L disodium hydrogen phosphate and 0.1mol / L citric acid uniformly at a volume ratio of 10:9 to obtain a buffer solution; in parts by weight, Weigh 100 parts of deionized water, 30 parts of phosphoric acid, 20 parts of compound surfactant, 10 parts of buffer solution, 20 parts of gum arabic, and 6 parts of silica sol, first mix the buffer solution, phosphoric acid and deionized water, and stir After stirring at a speed of 60r / min until it is completely dissolved, a mixed solution A is obtained. Heat the mixed solution A to 40°C, add gum arabic and silica sol, stir at a stirring speed of 100r / min until the materials are completely dissolved and dispersed, and then cool to At room temper...

example 2

[0022] Mix sodium dodecylbenzene sulfonate and lauryl amidopropyl betaine evenly at a mass ratio of 1:1 to obtain a mixture. At a rotational speed of 40r / min, mix NEUF-160h and D114 at a mass ratio of 1:1:5 Add it into the mixture and stir for 40 minutes to obtain a compound surfactant; mix 0.2mol / L disodium hydrogen phosphate and 0.1mol / L citric acid uniformly at a volume ratio of 10:9 to obtain a buffer solution; in parts by weight, Weigh 110 parts of deionized water, 40 parts of phosphoric acid, 30 parts of compound surfactant, 13 parts of buffer solution, 24 parts of gum arabic, and 11 parts of silica sol, first mix the buffer solution, phosphoric acid and deionized water, and stir After stirring at a speed of 70r / min until it is completely dissolved, a mixed solution A is obtained. Heat the mixed solution A to 45°C, add gum arabic and silica sol, stir at a stirring speed of 125r / min until the materials are completely dissolved and dispersed, and then cool to At room tempe...

example 3

[0024] Mix sodium dodecylbenzenesulfonate and lauryl amidopropyl betaine evenly at a mass ratio of 1:1 to obtain a mixture, and mix NEUF-160h and D114 at a mass ratio of 1:1:5 at a rotational speed of 50r / min Add it into the mixture and stir for 50 minutes to obtain a compound surfactant; mix 0.2mol / L disodium hydrogen phosphate and 0.1mol / L citric acid uniformly at a volume ratio of 10:9 to obtain a buffer solution; in parts by weight, Weigh 120 parts of deionized water, 50 parts of phosphoric acid, 40 parts of compound surfactant, 16 parts of buffer solution, 28 parts of gum arabic, and 16 parts of silica sol, first mix buffer solution, phosphoric acid and deionized water, and stir Stir at a speed of 80r / min until completely dissolved to obtain a mixed solution A. Heat the mixed solution A to 50°C, add gum arabic and silica sol, stir at a stirring speed of 150r / min until the materials are completely dissolved and dispersed, then cool to At room temperature, the mixture B was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com