PVC carpet raw material mixing device with high discharge rate

A mixing device and carpet technology, which is applied in the field of PVC carpet raw material mixing device with high discharge rate, can solve the problems of poor mixing effect, complex structure, poor fluidity, etc., and achieve good mixing effect, less raw material residue, and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

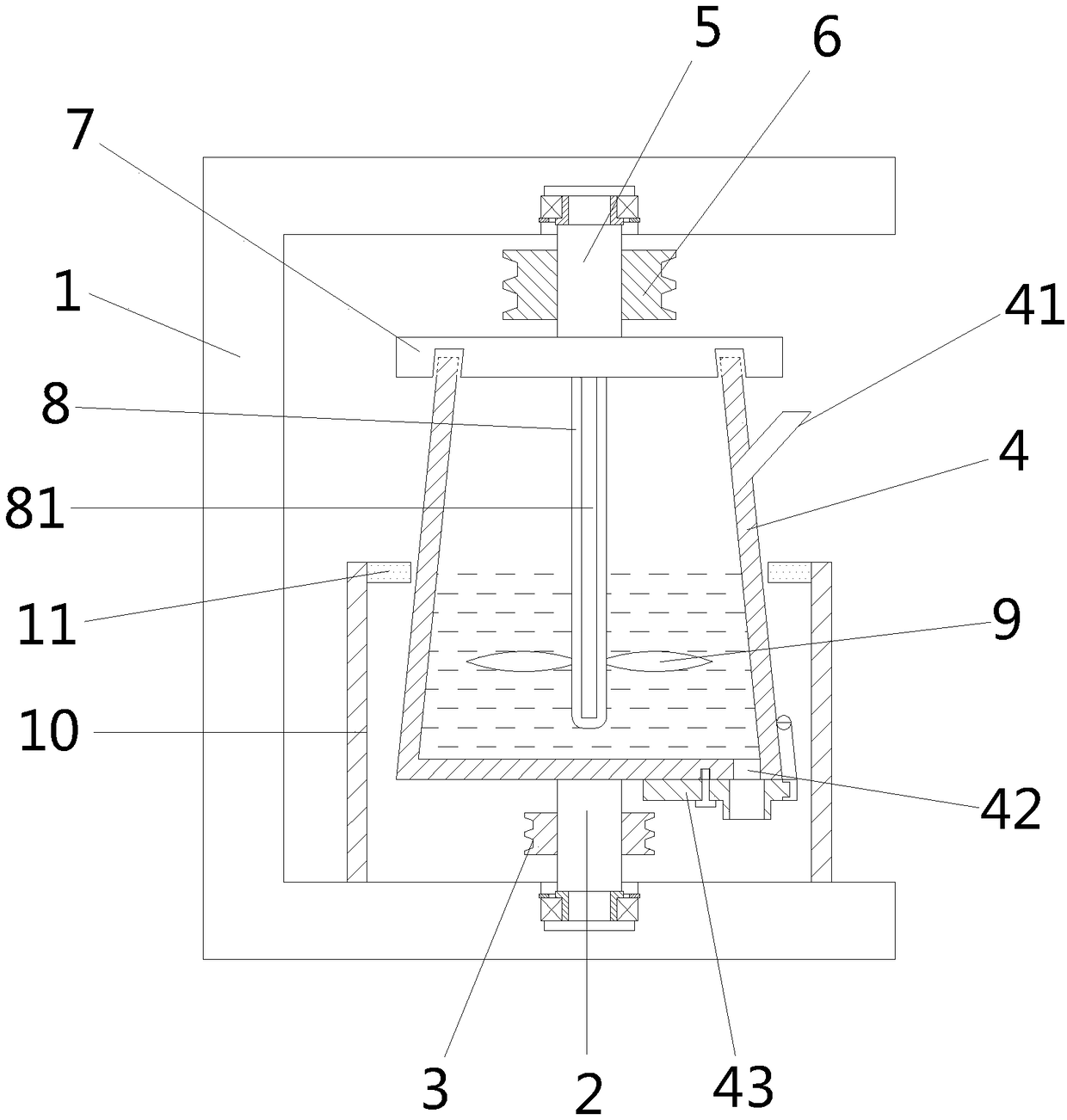

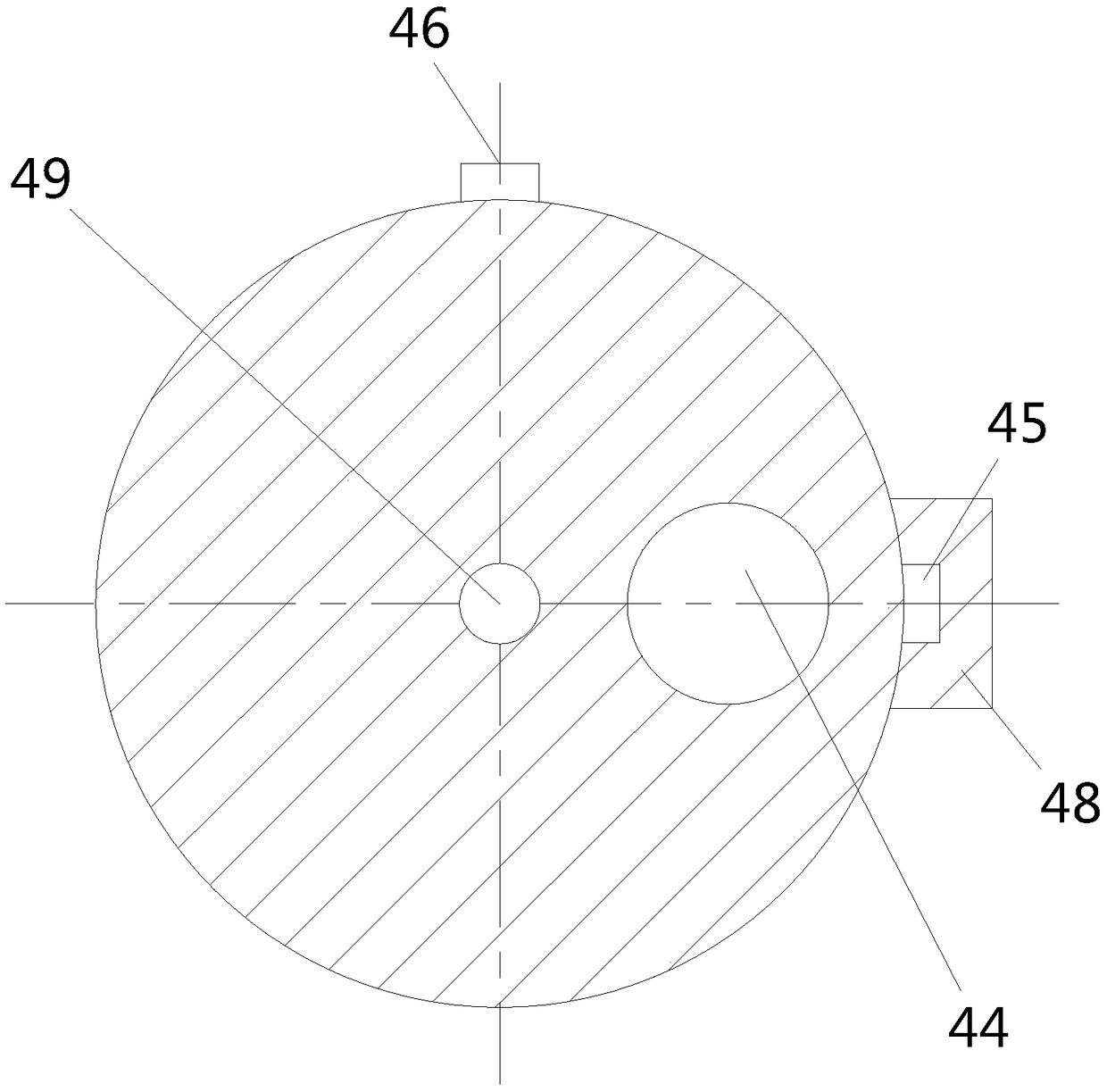

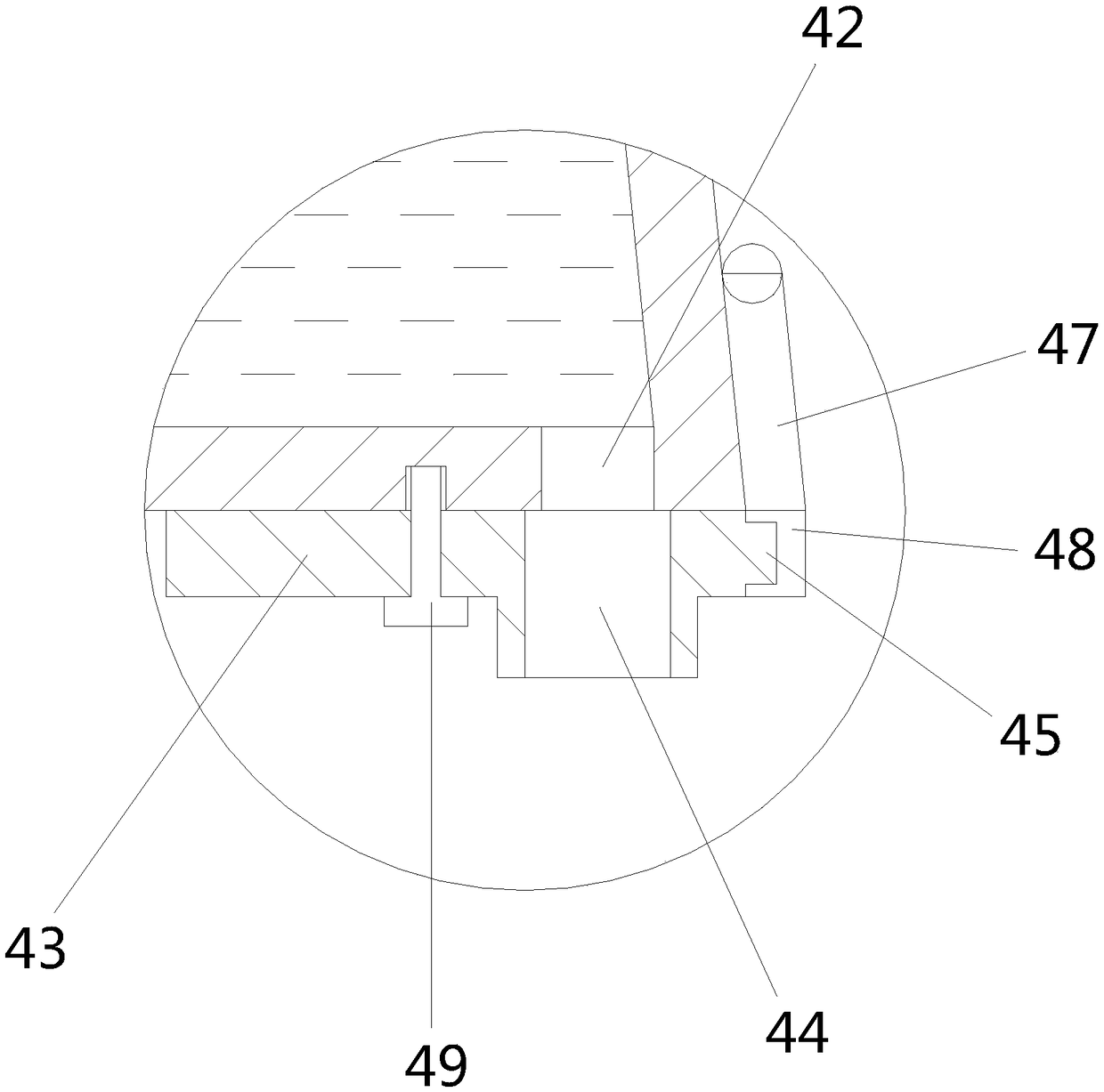

[0023] Embodiment: a kind of high discharging rate PVC carpet raw material mixing device, structure such as Figure 1 to Figure 6 As shown, it includes a C-shaped frame 1, the bottom surface of the C-shaped frame 1 is connected with a first rotating shaft 2 through a bearing, the first rotating shaft 2 is provided with a first pulley 3, and the end of the first rotating shaft 2 is connected with a drum 4 without a cover. The top surface of the C-shaped frame 1 is connected with a second rotating shaft 5 through bearings, the second rotating shaft 5 is provided with a second pulley 6, the end of the second rotating shaft 5 is connected with a cover 7, and the lower surface of the cover 7 is provided with a roller 4 The ring groove 71 that the top is fitted is vertical to the lower surface of the cover body 7 and is provided with a stirring shaft 8, and the stirring shaft 8 is provided with a stirring blade 9; the side wall of the drum 4 is provided with a feed inlet 41, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com