Slicing device for functional food processing

A technology of functional food and slicing device, which is applied in metal processing and other directions, can solve the problems of insufficient smoothness and rules of slicing, and achieve the effects of strong comprehensive practicability, easy promotion and use, and simple design and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

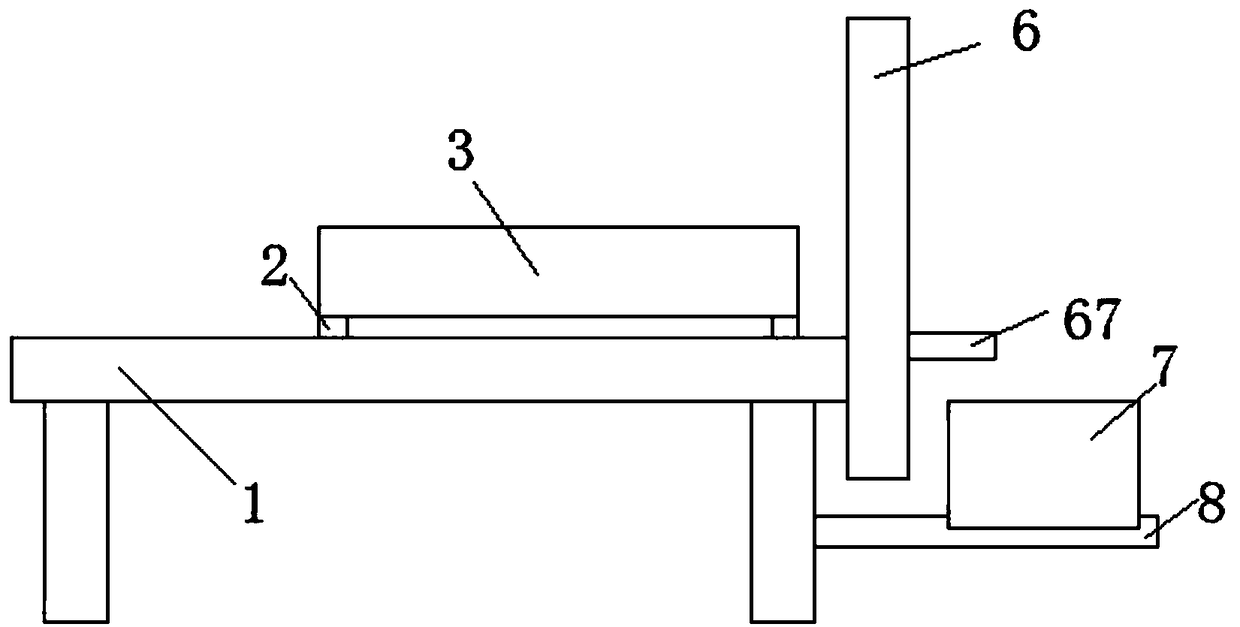

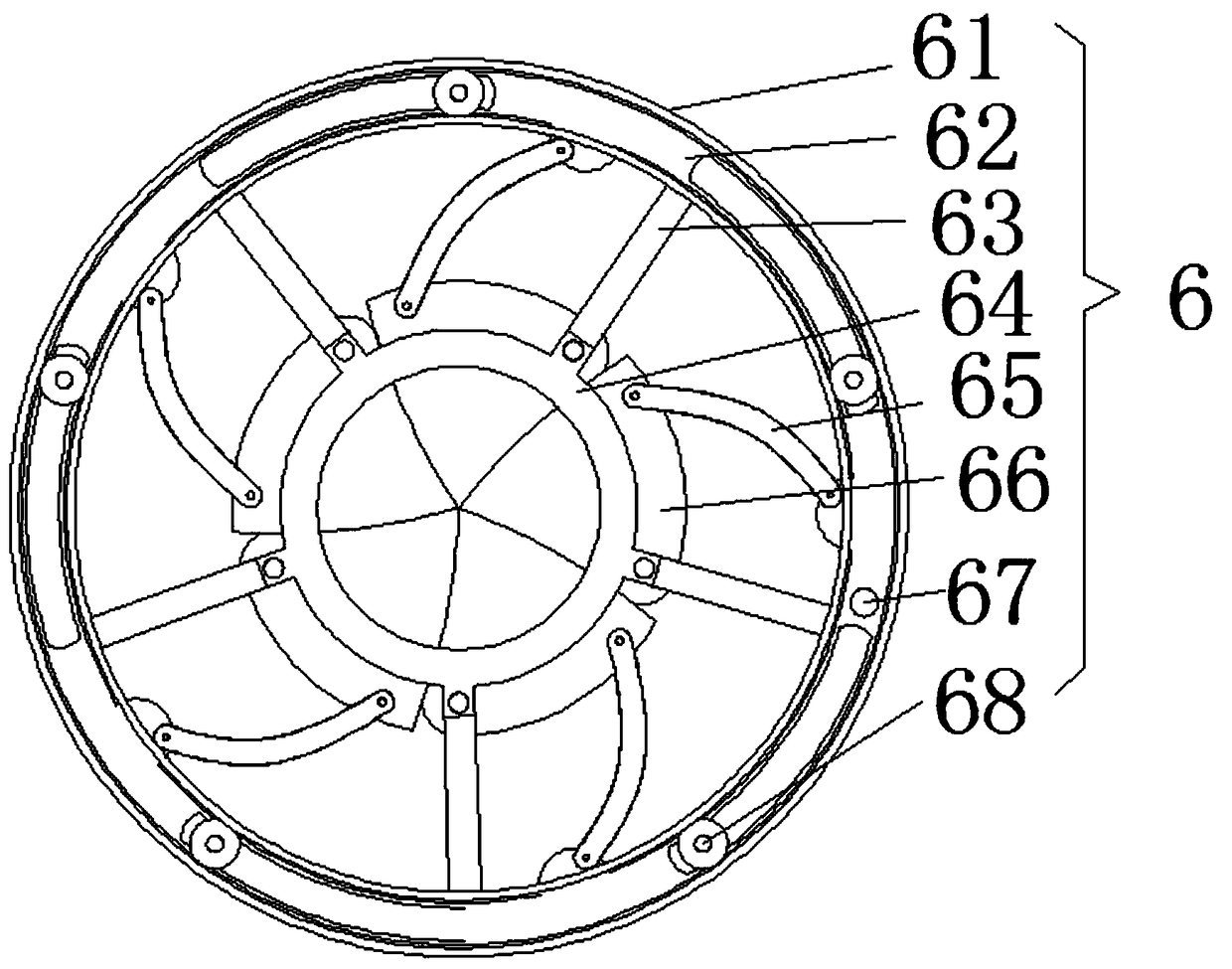

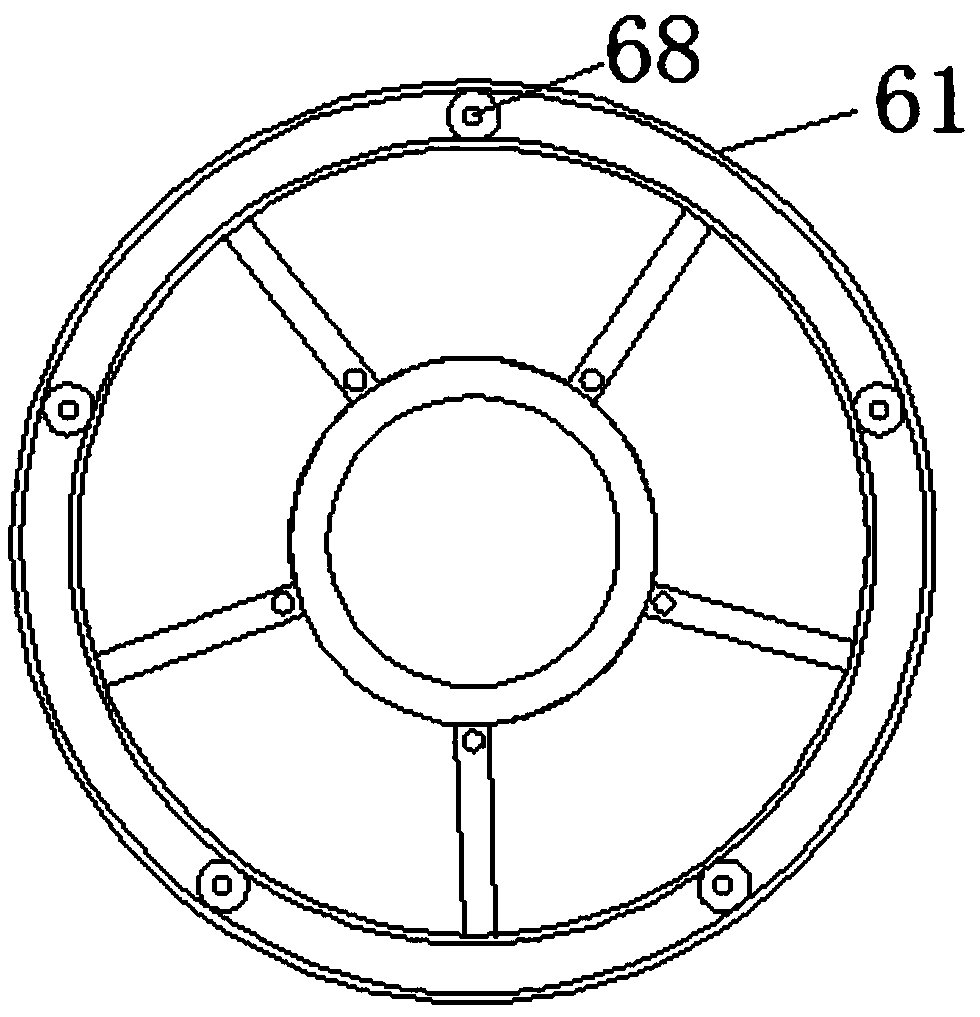

Embodiment 1

[0026] see Figure 1-6 , the present embodiment provides a functional food processing slicing device, a functional food processing slicing device, including a workbench 1 and a collection box 7, a support frame 2 is fixedly installed on the workbench 1, and the top of the support frame 2 The feed pipe 3 is fixedly installed, the side of the workbench 1 is respectively fixedly installed with a slicing device 6 and a placement table 8, the collection box 7 is placed on the placement table 8, and the cutting device 6 includes an annular installation table 61, an annular workbench 62, and a support rod. 63. Annular limiter 64, connecting rod 65, cutting knife 66, hand rocker 67 and limiter column 68, limiter column 68 is fixedly installed on the inner wall of the chute of annular installation platform 61, and annular limiter 64 passes through the support bar 63 is fixed on the inside of the ring mounting table 61, the ring table 62 is slidingly connected with the ring mounting tab...

Embodiment 2

[0029] see Figure 7 , made a further improvement on the basis of Embodiment 1: the cutting knife 66 can also be hinged on the end of the support rod 63 near the annular limiter 64, which increases the length of the cutting knife 66 and facilitates the rotation of the cutting knife 66, making the food It is easier to slice and improve slice efficiency.

[0030] Wherein, the ring-shaped workbench 62 is provided with five limit openings, and the ring-shaped mounting table 61 is stuck in the chute of the ring-shaped workbench 62 by the limit post 68. This enables the ring-shaped worktable 62 to slide in the chute of the ring-shaped workbench 62 in an orderly manner, thereby improving the slicing efficiency.

[0031] Wherein, the shape of the connecting rod 65 is not limited, as a preferred connecting rod is an arc rod, so that the annular worktable 62 can better drive the cutting knife 66 to rotate. In addition, there are five cutting knives 66 , and the five cutting knives 66 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com